Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

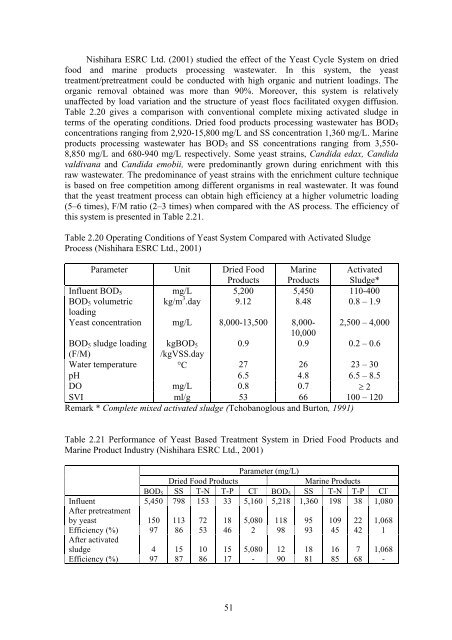

Nishihara ESRC Ltd. (2001) studied <strong>th</strong>e effect <strong>of</strong> <strong>th</strong>e Yeast Cycle System on dried<br />

food and marine products processing wastewater. In <strong>th</strong>is system, <strong>th</strong>e yeast<br />

treatment/pretreatment could be conducted wi<strong>th</strong> high organic and nutrient loadings. The<br />

organic removal obtained was more <strong>th</strong>an 90%. Moreover, <strong>th</strong>is system is relatively<br />

unaffected by load variation and <strong>th</strong>e structure <strong>of</strong> yeast flocs f<strong>ac</strong>ilitated oxygen diffusion.<br />

Table 2.20 gives a comparison wi<strong>th</strong> conventional complete mixing <strong>ac</strong>tivated sludge in<br />

terms <strong>of</strong> <strong>th</strong>e operating conditions. Dried food products processing wastewater has BOD5<br />

concentrations ranging from 2,920-15,800 mg/L and SS concentration 1,360 mg/L. Marine<br />

products processing wastewater has BOD5 and SS concentrations ranging from 3,550-<br />

8,850 mg/L and 680-940 mg/L respectively. Some yeast strains, Candida edax, Candida<br />

valdivana and Candida emobii, were predominantly grown during enrichment wi<strong>th</strong> <strong>th</strong>is<br />

raw wastewater. The predominance <strong>of</strong> yeast strains wi<strong>th</strong> <strong>th</strong>e enrichment culture technique<br />

is based on free competition among different organisms in real wastewater. It was found<br />

<strong>th</strong>at <strong>th</strong>e yeast treatment process can obtain high efficiency at a higher volumetric loading<br />

(5–6 times), F/M ratio (2–3 times) when compared wi<strong>th</strong> <strong>th</strong>e AS process. The efficiency <strong>of</strong><br />

<strong>th</strong>is system is presented in Table 2.21.<br />

Table 2.20 Operating Conditions <strong>of</strong> Yeast System Compared wi<strong>th</strong> Activated Sludge<br />

Process (Nishihara ESRC Ltd., 2001)<br />

Parameter Unit Dried Food Marine Activated<br />

Products Products Sludge*<br />

Influent BOD5<br />

BOD5 volumetric<br />

loading<br />

mg/L<br />

kg/m<br />

5,200 5,450 110-400<br />

3 .day 9.12 8.48 0.8 – 1.9<br />

Yeast concentration mg/L 8,000-13,500 8,000-<br />

10,000<br />

2,500 – 4,000<br />

BOD5 sludge loading kgBOD5 0.9 0.9 0.2 – 0.6<br />

(F/M)<br />

/kgVSS.day<br />

Water temperature °C 27 26 23 – 30<br />

pH 6.5 4.8 6.5 – 8.5<br />

DO mg/L 0.8 0.7 ≥ 2<br />

SVI ml/g 53 66 100 – 120<br />

Remark * Complete mixed <strong>ac</strong>tivated sludge (Tchobanoglous and Burton, 1991)<br />

Table 2.21 Performance <strong>of</strong> Yeast Based Treatment System in Dried Food Products and<br />

Marine Product Industry (Nishihara ESRC Ltd., 2001)<br />

Parameter (mg/L)<br />

Dried Food Products Marine Products<br />

BOD5 SS T-N T-P Cl -<br />

BOD5 SS T-N T-P Cl -<br />

Influent<br />

After pretreatment<br />

5,450 798 153 33 5,160 5,218 1,360 198 38 1,080<br />

by yeast 150 113 72 18 5,080 118 95 109 22 1,068<br />

Efficiency (%)<br />

After <strong>ac</strong>tivated<br />

97 86 53 46 2 98 93 45 42 1<br />

sludge 4 15 10 15 5,080 12 18 16 7 1,068<br />

Efficiency (%) 97 87 86 17 - 90 81 85 68 -<br />

51