Download the file. - Groupe Seb

Download the file. - Groupe Seb

Download the file. - Groupe Seb

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

30<br />

FUNDAMENTALS<br />

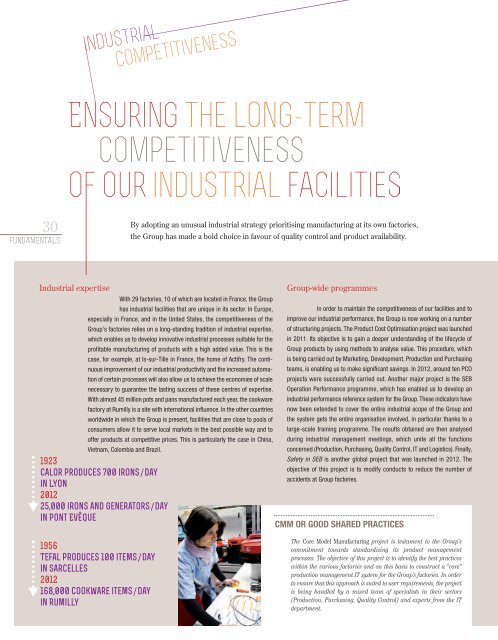

By adopting an unusual industrial strategy prioritising manufacturing at its own factories,<br />

<strong>the</strong> Group has made a bold choice in favour of quality control and product availability.<br />

Industrial expertise<br />

With 29 factories, 10 of which are located in France, <strong>the</strong> Group<br />

has industrial facilities that are unique in its sector. In Europe,<br />

especially in France, and in <strong>the</strong> United States, <strong>the</strong> competitiveness of <strong>the</strong><br />

Group's factories relies on a long-standing tradition of industrial expertise,<br />

which enables us to develop innovative industrial processes suitable for <strong>the</strong><br />

profitable manufacturing of products with a high added value. This is <strong>the</strong><br />

case, for example, at Is-sur-Tille in France, <strong>the</strong> home of Actifry. The continuous<br />

improvement of our industrial productivity and <strong>the</strong> increased automation<br />

of certain processes will also allow us to achieve <strong>the</strong> economies of scale<br />

necessary to guarantee <strong>the</strong> lasting success of <strong>the</strong>se centres of expertise.<br />

With almost 45 million pots and pans manufactured each year, <strong>the</strong> cookware<br />

factory at Rumilly is a site with international influence. In <strong>the</strong> o<strong>the</strong>r countries<br />

worldwide in which <strong>the</strong> Group is present, facilities that are close to pools of<br />

consumers allow it to serve local markets in <strong>the</strong> best possible way and to<br />

offer products at competitive prices. This is particularly <strong>the</strong> case in China,<br />

Vietnam, Colombia and Brazil.<br />

1923<br />

Calor produces 700 irons/day<br />

in Lyon<br />

2012<br />

25,000 irons and generators/day<br />

in Pont Evêque<br />

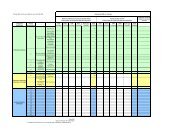

Group-wide programmes<br />

In order to maintain <strong>the</strong> competitiveness of our facilities and to<br />

improve our industrial performance, <strong>the</strong> Group is now working on a number<br />

of structuring projects. The Product Cost Optimisation project was launched<br />

in 2011. Its objective is to gain a deeper understanding of <strong>the</strong> lifecycle of<br />

Group products by using methods to analyse value. This procedure, which<br />

is being carried out by Marketing, Development, Production and Purchasing<br />

teams, is enabling us to make significant savings. In 2012, around ten PCO<br />

projects were successfully carried out. Ano<strong>the</strong>r major project is <strong>the</strong> SEB<br />

Operation Performance programme, which has enabled us to develop an<br />

industrial performance reference system for <strong>the</strong> Group. These indicators have<br />

now been extended to cover <strong>the</strong> entire industrial scope of <strong>the</strong> Group and<br />

<strong>the</strong> system gets <strong>the</strong> entire organisation involved, in particular thanks to a<br />

large-scale training programme. The results obtained are <strong>the</strong>n analysed<br />

during industrial management meetings, which unite all <strong>the</strong> functions<br />

concerned (Production, Purchasing, Quality Control, IT and Logistics). Finally,<br />

Safety in SEB is ano<strong>the</strong>r global project that was launched in 2012. The<br />

objective of this project is to modify conducts to reduce <strong>the</strong> number of<br />

accidents at Group factories.<br />

cmm or good Shared practiceS<br />

1956<br />

Tefal produces 100 items/day<br />

in Sarcelles<br />

2012<br />

168,000 cookware items/day<br />

in Rumilly<br />

The Core Model Manufacturing project is testament to <strong>the</strong> Group's<br />

commitment towards standardising its product management<br />

processes. The objective of this project is to identify <strong>the</strong> best practices<br />

within <strong>the</strong> various factories and on this basis to construct a "core"<br />

production management IT system for <strong>the</strong> Group's factories. In order<br />

to ensure that this approach is suited to user requirements, <strong>the</strong> project<br />

is being handled by a mixed team of specialists in <strong>the</strong>ir sectors<br />

(Production, Purchasing, Quality Control) and experts from <strong>the</strong> IT<br />

department.