Structural Health Monitoring Using Smart Sensors - ideals ...

Structural Health Monitoring Using Smart Sensors - ideals ...

Structural Health Monitoring Using Smart Sensors - ideals ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

equirements, appropriate middleware services will need to be adopted, modified, or<br />

developed.<br />

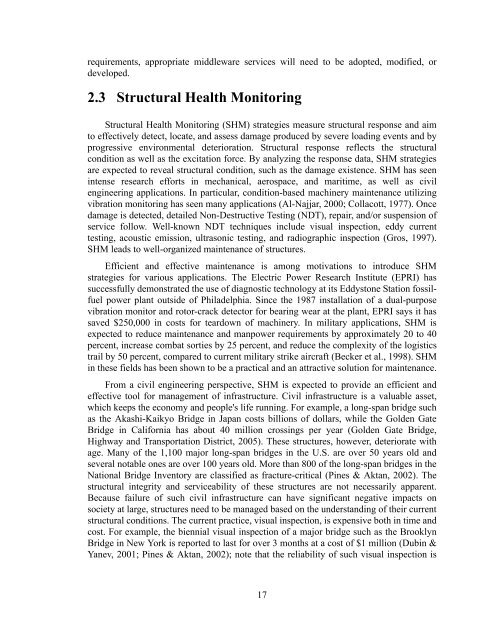

2.3 <strong>Structural</strong> <strong>Health</strong> <strong>Monitoring</strong><br />

<strong>Structural</strong> <strong>Health</strong> <strong>Monitoring</strong> (SHM) strategies measure structural response and aim<br />

to effectively detect, locate, and assess damage produced by severe loading events and by<br />

progressive environmental deterioration. <strong>Structural</strong> response reflects the structural<br />

condition as well as the excitation force. By analyzing the response data, SHM strategies<br />

are expected to reveal structural condition, such as the damage existence. SHM has seen<br />

intense research efforts in mechanical, aerospace, and maritime, as well as civil<br />

engineering applications. In particular, condition-based machinery maintenance utilizing<br />

vibration monitoring has seen many applications (Al-Najjar, 2000; Collacott, 1977). Once<br />

damage is detected, detailed Non-Destructive Testing (NDT), repair, and/or suspension of<br />

service follow. Well-known NDT techniques include visual inspection, eddy current<br />

testing, acoustic emission, ultrasonic testing, and radiographic inspection (Gros, 1997).<br />

SHM leads to well-organized maintenance of structures.<br />

Efficient and effective maintenance is among motivations to introduce SHM<br />

strategies for various applications. The Electric Power Research Institute (EPRI) has<br />

successfully demonstrated the use of diagnostic technology at its Eddystone Station fossilfuel<br />

power plant outside of Philadelphia. Since the 1987 installation of a dual-purpose<br />

vibration monitor and rotor-crack detector for bearing wear at the plant, EPRI says it has<br />

saved $250,000 in costs for teardown of machinery. In military applications, SHM is<br />

expected to reduce maintenance and manpower requirements by approximately 20 to 40<br />

percent, increase combat sorties by 25 percent, and reduce the complexity of the logistics<br />

trail by 50 percent, compared to current military strike aircraft (Becker et al., 1998). SHM<br />

in these fields has been shown to be a practical and an attractive solution for maintenance.<br />

From a civil engineering perspective, SHM is expected to provide an efficient and<br />

effective tool for management of infrastructure. Civil infrastructure is a valuable asset,<br />

which keeps the economy and people's life running. For example, a long-span bridge such<br />

as the Akashi-Kaikyo Bridge in Japan costs billions of dollars, while the Golden Gate<br />

Bridge in California has about 40 million crossings per year (Golden Gate Bridge,<br />

Highway and Transportation District, 2005). These structures, however, deteriorate with<br />

age. Many of the 1,100 major long-span bridges in the U.S. are over 50 years old and<br />

several notable ones are over 100 years old. More than 800 of the long-span bridges in the<br />

National Bridge Inventory are classified as fracture-critical (Pines & Aktan, 2002). The<br />

structural integrity and serviceability of these structures are not necessarily apparent.<br />

Because failure of such civil infrastructure can have significant negative impacts on<br />

society at large, structures need to be managed based on the understanding of their current<br />

structural conditions. The current practice, visual inspection, is expensive both in time and<br />

cost. For example, the biennial visual inspection of a major bridge such as the Brooklyn<br />

Bridge in New York is reported to last for over 3 months at a cost of $1 million (Dubin &<br />

Yanev, 2001; Pines & Aktan, 2002); note that the reliability of such visual inspection is<br />

17