Structural Health Monitoring Using Smart Sensors - ideals ...

Structural Health Monitoring Using Smart Sensors - ideals ...

Structural Health Monitoring Using Smart Sensors - ideals ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

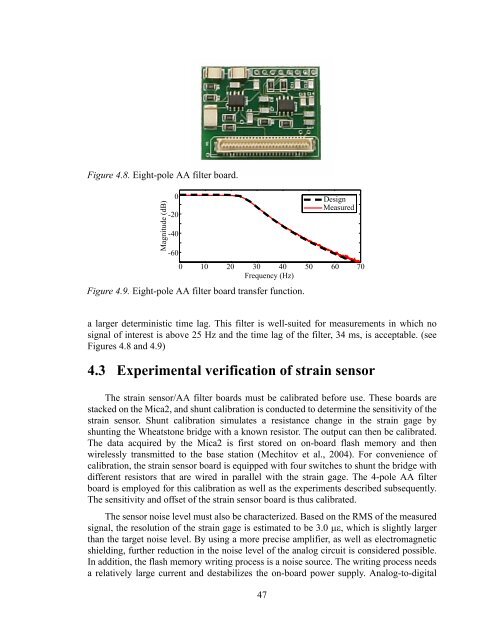

Figure 4.8. Eight-pole AA filter board.<br />

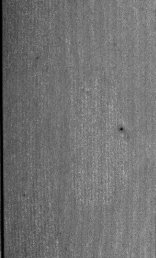

Magnitude (dB)<br />

0<br />

-20<br />

-40<br />

-60<br />

0 10 20 30 40 50 60 70<br />

Frequency (Hz)<br />

Figure 4.9. Eight-pole AA filter board transfer function.<br />

Design<br />

Measured<br />

a larger deterministic time lag. This filter is well-suited for measurements in which no<br />

signal of interest is above 25 Hz and the time lag of the filter, 34 ms, is acceptable. (see<br />

Figures 4.8 and 4.9)<br />

4.3 Experimental verification of strain sensor<br />

The strain sensor/AA filter boards must be calibrated before use. These boards are<br />

stacked on the Mica2, and shunt calibration is conducted to determine the sensitivity of the<br />

strain sensor. Shunt calibration simulates a resistance change in the strain gage by<br />

shunting the Wheatstone bridge with a known resistor. The output can then be calibrated.<br />

The data acquired by the Mica2 is first stored on on-board flash memory and then<br />

wirelessly transmitted to the base station (Mechitov et al., 2004). For convenience of<br />

calibration, the strain sensor board is equipped with four switches to shunt the bridge with<br />

different resistors that are wired in parallel with the strain gage. The 4-pole AA filter<br />

board is employed for this calibration as well as the experiments described subsequently.<br />

The sensitivity and offset of the strain sensor board is thus calibrated.<br />

The sensor noise level must also be characterized. Based on the RMS of the measured<br />

signal, the resolution of the strain gage is estimated to be 3.0 , which is slightly larger<br />

than the target noise level. By using a more precise amplifier, as well as electromagnetic<br />

shielding, further reduction in the noise level of the analog circuit is considered possible.<br />

In addition, the flash memory writing process is a noise source. The writing process needs<br />

a relatively large current and destabilizes the on-board power supply. Analog-to-digital<br />

47