Manual on the Development of Cleaner Production Policies ... - Unido

Manual on the Development of Cleaner Production Policies ... - Unido

Manual on the Development of Cleaner Production Policies ... - Unido

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DEVELOPMENT OF CP POLICY<br />

MODULE 1: INTRODUCING CP<br />

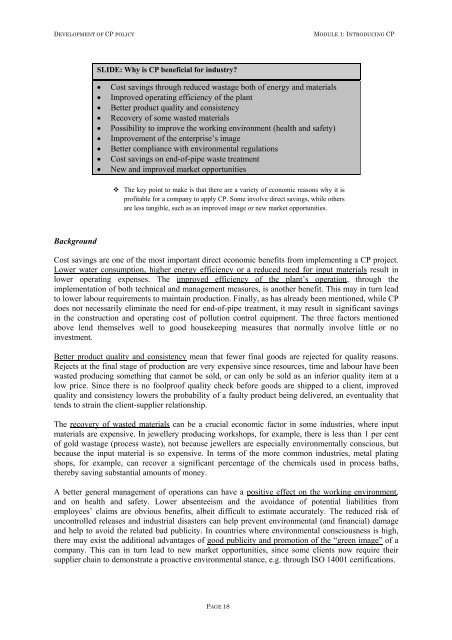

SLIDE: Why is CP beneficial for industry?<br />

• Cost savings through reduced wastage both <strong>of</strong> energy and materials<br />

• Improved operating efficiency <strong>of</strong> <strong>the</strong> plant<br />

• Better product quality and c<strong>on</strong>sistency<br />

• Recovery <strong>of</strong> some wasted materials<br />

• Possibility to improve <strong>the</strong> working envir<strong>on</strong>ment (health and safety)<br />

• Improvement <strong>of</strong> <strong>the</strong> enterprise’s image<br />

• Better compliance with envir<strong>on</strong>mental regulati<strong>on</strong>s<br />

• Cost savings <strong>on</strong> end-<strong>of</strong>-pipe waste treatment<br />

• New and improved market opportunities<br />

The key point to make is that <strong>the</strong>re are a variety <strong>of</strong> ec<strong>on</strong>omic reas<strong>on</strong>s why it is<br />

pr<strong>of</strong>itable for a company to apply CP. Some involve direct savings, while o<strong>the</strong>rs<br />

are less tangible, such as an improved image or new market opportunities.<br />

Background<br />

Cost savings are <strong>on</strong>e <strong>of</strong> <strong>the</strong> most important direct ec<strong>on</strong>omic benefits from implementing a CP project.<br />

Lower water c<strong>on</strong>sumpti<strong>on</strong>, higher energy efficiency or a reduced need for input materials result in<br />

lower operating expenses. The improved efficiency <strong>of</strong> <strong>the</strong> plant’s operati<strong>on</strong>, through <strong>the</strong><br />

implementati<strong>on</strong> <strong>of</strong> both technical and management measures, is ano<strong>the</strong>r benefit. This may in turn lead<br />

to lower labour requirements to maintain producti<strong>on</strong>. Finally, as has already been menti<strong>on</strong>ed, while CP<br />

does not necessarily eliminate <strong>the</strong> need for end-<strong>of</strong>-pipe treatment, it may result in significant savings<br />

in <strong>the</strong> c<strong>on</strong>structi<strong>on</strong> and operating cost <strong>of</strong> polluti<strong>on</strong> c<strong>on</strong>trol equipment. The three factors menti<strong>on</strong>ed<br />

above lend <strong>the</strong>mselves well to good housekeeping measures that normally involve little or no<br />

investment.<br />

Better product quality and c<strong>on</strong>sistency mean that fewer final goods are rejected for quality reas<strong>on</strong>s.<br />

Rejects at <strong>the</strong> final stage <strong>of</strong> producti<strong>on</strong> are very expensive since resources, time and labour have been<br />

wasted producing something that cannot be sold, or can <strong>on</strong>ly be sold as an inferior quality item at a<br />

low price. Since <strong>the</strong>re is no foolpro<strong>of</strong> quality check before goods are shipped to a client, improved<br />

quality and c<strong>on</strong>sistency lowers <strong>the</strong> probability <strong>of</strong> a faulty product being delivered, an eventuality that<br />

tends to strain <strong>the</strong> client-supplier relati<strong>on</strong>ship.<br />

The recovery <strong>of</strong> wasted materials can be a crucial ec<strong>on</strong>omic factor in some industries, where input<br />

materials are expensive. In jewellery producing workshops, for example, <strong>the</strong>re is less than 1 per cent<br />

<strong>of</strong> gold wastage (process waste), not because jewellers are especially envir<strong>on</strong>mentally c<strong>on</strong>scious, but<br />

because <strong>the</strong> input material is so expensive. In terms <strong>of</strong> <strong>the</strong> more comm<strong>on</strong> industries, metal plating<br />

shops, for example, can recover a significant percentage <strong>of</strong> <strong>the</strong> chemicals used in process baths,<br />

<strong>the</strong>reby saving substantial amounts <strong>of</strong> m<strong>on</strong>ey.<br />

A better general management <strong>of</strong> operati<strong>on</strong>s can have a positive effect <strong>on</strong> <strong>the</strong> working envir<strong>on</strong>ment,<br />

and <strong>on</strong> health and safety. Lower absenteeism and <strong>the</strong> avoidance <strong>of</strong> potential liabilities from<br />

employees’ claims are obvious benefits, albeit difficult to estimate accurately. The reduced risk <strong>of</strong><br />

unc<strong>on</strong>trolled releases and industrial disasters can help prevent envir<strong>on</strong>mental (and financial) damage<br />

and help to avoid <strong>the</strong> related bad publicity. In countries where envir<strong>on</strong>mental c<strong>on</strong>sciousness is high,<br />

<strong>the</strong>re may exist <strong>the</strong> additi<strong>on</strong>al advantages <strong>of</strong> good publicity and promoti<strong>on</strong> <strong>of</strong> <strong>the</strong> “green image” <strong>of</strong> a<br />

company. This can in turn lead to new market opportunities, since some clients now require <strong>the</strong>ir<br />

supplier chain to dem<strong>on</strong>strate a proactive envir<strong>on</strong>mental stance, e.g. through ISO 14001 certificati<strong>on</strong>s.<br />

PAGE 18