Accusetter Manual - BC MacDonald & Co.

Accusetter Manual - BC MacDonald & Co.

Accusetter Manual - BC MacDonald & Co.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Gaging Formulas<br />

The gaging formula under FUNCTION on the <strong>Accusetter</strong> II allows the user to add,<br />

subtract, multiply, or divide inputs from transducers A, B, C, and D. The <strong>Accusetter</strong> II<br />

requires a gaging formula for all applications programmed in the Multiple Check and<br />

Multiple Fixture programs.<br />

For air gaging applications, the gaging formula will always be 1.000 for Input A or Input B.<br />

For electronic gaging applications using LVDTs, the gaging formula will be dependent<br />

upon the specific gaging application.<br />

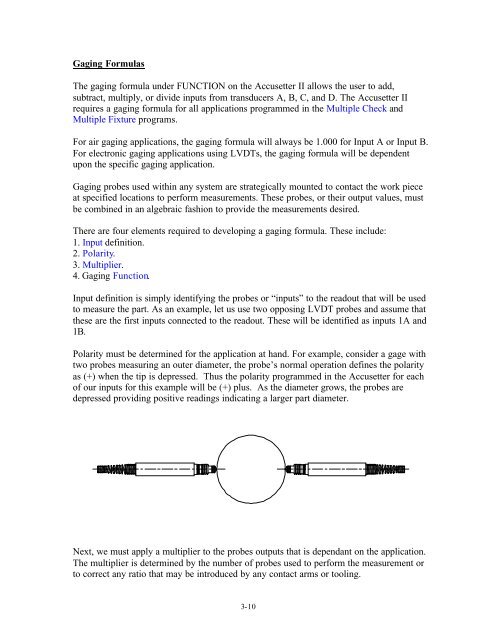

Gaging probes used within any system are strategically mounted to contact the work piece<br />

at specified locations to perform measurements. These probes, or their output values, must<br />

be combined in an algebraic fashion to provide the measurements desired.<br />

There are four elements required to developing a gaging formula. These include:<br />

1. Input definition.<br />

2. Polarity.<br />

3. Multiplier.<br />

4. Gaging Function.<br />

Input definition is simply identifying the probes or “inputs” to the readout that will be used<br />

to measure the part. As an example, let us use two opposing LVDT probes and assume that<br />

these are the first inputs connected to the readout. These will be identified as inputs 1A and<br />

1B.<br />

Polarity must be determined for the application at hand. For example, consider a gage with<br />

two probes measuring an outer diameter, the probe’s normal operation defines the polarity<br />

as (+) when the tip is depressed. Thus the polarity programmed in the <strong>Accusetter</strong> for each<br />

of our inputs for this example will be (+) plus. As the diameter grows, the probes are<br />

depressed providing positive readings indicating a larger part diameter.<br />

Next, we must apply a multiplier to the probes outputs that is dependant on the application.<br />

The multiplier is determined by the number of probes used to perform the measurement or<br />

to correct any ratio that may be introduced by any contact arms or tooling.<br />

3-10