You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

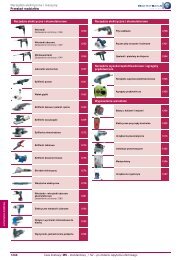

Lathe and rounding machine accessoriesTool holders for NC lathesMetal-cutting toolsContinued next pageVDI Solid Clampstool holding fixtureApplication: for assembling and dismantling.Tool holding fixtures VDI (69880)Size 30 40 5023912 Ident. No. 530 540 550Unit price E O. R. O. R. O. R.Prod. Gr. 280DIN 69880Continued next pageTool headsfor geared tools on CNC lathesThe tool heads are intended for mounting in the turret of a (4-axis) CNC turning machine with DIN 69880-1 shank (shank Ø 20/30/40/50). Drive coupling designed as front coupling or multi-spline profile,depending on the machine design and type. Profiles according to DIN 5480 and 5482 are as common frontcouplings, e g. DIN 1809.High-precision axial and radial tool heads are suitable for both clockwise and anti-clockwise rotation; theinput direction of rotation corresponds to the output direction of rotation. Different gear ratios allow for theadjustment of required cutting conditions, depending on the tool used for the individual application.The tool heads are manufactured with external and also with internal coolant supply. Safe sealing and permanentgrease lubrication ensure long service life.The machine brand, type and shank holder must be indicated on enquiries and orders.Continued next pageExamples:Tool headsfor geared tools, with shank DIN 69880 for use on CNC lathes (4 axes)Drilling and milling head adjustablethrough 0°-90°Milling head DIN 6358radialDrilling and milling headradial offsetDrilling and milling headaxial offsetDrilling and milling headradialDrilling and milling headaxialContinued next pageRevolving interfacesDIN 5480 withtwisting security deviceDIN 5482 DIN 1809 TOEM INDEXContinued next pageBasic holders and insertsfor geared toolsThis system allows for flexible and high-precision changing of toolheads on the machine tool. Major benefits include:•cutting tools lie preset on the machine•quick change via one tightening position only•clamping of inserts free of transverse force•tool change without risks of injury•secure torque transmission•short designh Additional information, advice and quotations availableon request.Product video:use your mobile phone to scan the QR code.582 2011/12