Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

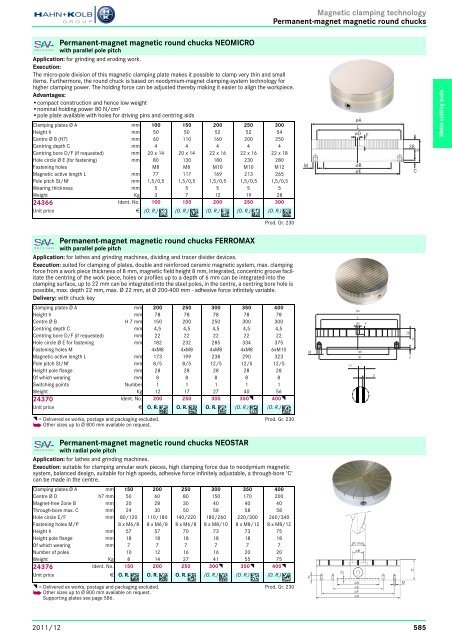

Magnetic clamping technologyPermanent-magnet magnetic round chucksContinued next pagePermanent-magnet magnetic round chucks NEOMICROwith parallel pole pitchApplication: for grinding and eroding work.Execution:The micro-pole division of this magnetic clamping plate makes it possible to clamp very thin and smallitems. Furthermore, the round chuck is based on neodymium-magnet clamping-system technology forhigher clamping power. The holding force can be adjusted thereby making it easier to align the workpiece.Advantages:•compact construction and hence low weight•nominal holding power 80 N/cm²•pole plate available with holes for driving pins and centring aids<strong>Clamping</strong> plates Ø A mm 100 150 200 250 300Height h mm 50 50 52 52 54Centre Ø B (H7) mm 60 110 160 200 250Centring depth C mm 4 4 4 4 4Centring bore D/F (if requested) mm 20 x 14 20 x 14 22 x 16 22 x 16 22 x 18Hole circle Ø E (for fastening) mm 80 130 180 230 280Fastening holes M8 M8 M10 M10 M12Magnetic active length L mm 77 117 169 213 265Pole pitch St/Nf mm 1,5/0,5 1,5/0,5 1,5/0,5 1,5/0,5 1,5/0,5Wearing thickness mm 5 5 5 5 5Weight Kg 3 7 12 19 2824366 Ident. No. 100 150 200 250 300Unit price E (O. R.) (O. R.) (O. R.) (O. R.) (O. R.)MALDBEF28 HCMetal-cutting toolsProd. Gr. 230Continued next pagePermanent-magnet magnetic round chucks FERROMAXwith parallel pole pitchApplication: for lathes and grinding machines, dividing and tracer divider devices.Execution: suited for clamping of plates, double and reinforced ceramic magnetic system, max. clampingforce from a work piece thickness of 8 mm, magnetic field height 8 mm, integrated, concentric groove facilitatethe centring of the work piece, holes or profiles up to a depth of 6 mm can be integrated into theclamping surface, up to 22 mm can be integrated into the steel poles, in the centre, a centring bore hole ispossible, max. depth 22 mm, max. Ø 22 mm, at Ø 200-400 mm - adhesive force infinitely variable.Delivery: with chuck key<strong>Clamping</strong> plates Ø A mm 200 250 300 350 400Height h mm 78 78 78 78 78Centre Ø B H 7 mm 150 200 250 300 300Centring depth C mm 4,5 4,5 4,5 4,5 4,5Centring bore D/F (if requested) mm 22 22 22 22 22Hole circle Ø E for fastening mm 182 232 285 334 375Fastening holes M 4xM8 4xM8 4xM8 4xM8 6xM10Magnetic active length L mm 173 199 238 290 323Pole pitch St/Nf mm 8/5 8/5 12/5 12/5 12/5Height pole flange mm 28 28 28 28 28Of which wearing mm 8 8 8 8 8Switching points Number 1 1 1 1 1Weight Kg 12 17 27 40 5624370 Ident. No. 200 250 300 350d 400dUnit price E O. R. O. R. O. R. (O. R.) (O. R.)d = Delivered ex works, postage and packaging excluded.h Other sizes up to Ø 800 mm available on request.Prod. Gr. 230Continued next pagePermanent-magnet magnetic round chucks NEOSTARwith radial pole pitchApplication: for lathes and grinding machines.Execution: suitable for clamping annular work pieces, high clamping force due to neodymium magneticsystem, balanced design, suitable for high speeds, adhesive force infinitely adjustable, a through-bore 'C'can be made in the centre.<strong>Clamping</strong> plates Ø A mm 150 200 250 300 350 400Centre Ø D h7 mm 50 60 80 150 170 200Magnet-free Zone B mm 20 28 30 40 40 40Through-bore max. C mm 24 30 50 58 58 58Hole circle E/F mm 80/120 110/180 140/220 180/260 220/300 260/340Fastening holes M/P 8 x M6/8 8 x M6/8 8 x M6/8 8 x M8/10 8 x M8/12 8 x M8/12Height h mm 57 57 70 73 73 75Height pole flange mm 18 18 18 18 18 18Of which wearing mm 7 7 7 7 7 7Number of poles 10 12 16 16 20 20Weight Kg 8 14 27 41 55 7524376 Ident. No. 150 200 250 300d 350d 400dUnit price E O. R. O. R. O. R. (O. R.) (O. R.) (O. R.)d = Delivered ex works, postage and packaging excluded.h Other sizes up to Ø 800 mm available on request.Supporting plates see page 586.Prod. Gr. 230PGC max.BDEFAMH2011/12585