Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

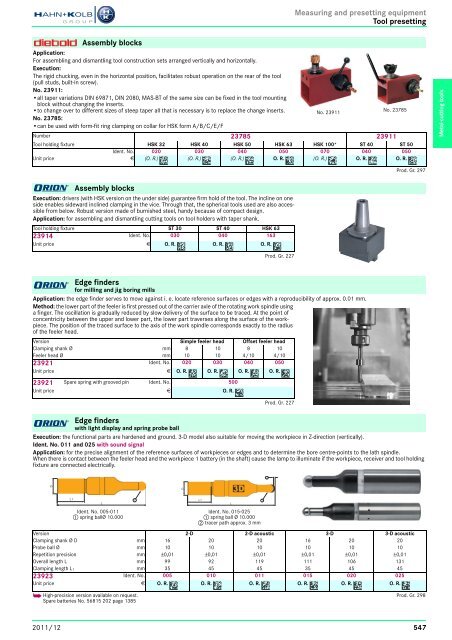

Measuring and presetting equipmentTool presettingContinued next pageAssembly blocksApplication:For assembling and dismantling tool construction sets arranged vertically and horizontally.Execution:The rigid chucking, even in the horizontal position, facilitates robust operation on the rear of the tool(pull studs, built-in screw).No. 23911:•all taper variations DIN 69871, DIN 2080, MAS-BT of the same size can be fixed in the tool mountingblock without changing the inserts.•to change over to different sizes of steep taper all that is necessary is to replace the change inserts.No. 23785:•can be used with form-fit ring clamping on collar for HSK form A/B/C/E/FNo. 23911No. 23785Number 23785 23911Tool holding fixture HSK 32 HSK 40 HSK 50 HSK 63 HSK 100* ST 40 ST 50Ident. No. 020 030 040 050 070 040 050Unit price E (O. R.) (O. R.) (O. R.) O. R. (O. R.) O. R. O. R.Metal-cutting toolsProd. Gr. 297Continued next pageAssembly blocksExecution: drivers (with HSK version on the under side) guarantee firm hold of the tool. The incline on oneside enables sideward inclined clamping in the vice. Through that, the spherical tools used are also accessiblefrom below. Robust version made of burnished steel, handy because of compact design.Application: for assembling and dismantling cutting tools on tool holders with taper shank.Tool holding fixture ST 30 ST 40 HSK 6323914 Ident. No. 030 040 163Unit price E O. R. O. R. O. R.Prod. Gr. 227Continued next pageEdge findersfor milling and jig boring millsApplication: the edge finder serves to move against i. e. locate reference surfaces or edges with a reproducibility of approx. 0.01 mm.Method: the lower part of the feeler is first pressed out of the carrier axle of the rotating work spindle usinga finger. The oscillation is gradually reduced by slow delivery of the surface to be traced. At the point ofconcentricity between the upper and lower part, the lower part traverses along the surface of the workpiece.The position of the traced surface to the axis of the work spindle corresponds exactly to the radiusof the feeler head.Version Simple feeler head Offset feeler head<strong>Clamping</strong> shank Ø mm 8 10 8 10Feeler head Ø mm 10 10 4/10 4/1023921 Ident. No. 020 030 040 050Unit price E O. R. O. R. O. R. O. R.23921 Spare spring with grooved pin Ident. No. 500Unit price E O. R.Prod. Gr. 227Continued next pageEdge finderswith light display and spring probe ballExecution: the functional parts are hardened and ground. 3-D model also suitable for moving the workpiece in Z-direction (vertically).Ident. No. 011 and 025 with sound signalApplication: for the precise alignment of the reference surfaces of workpieces or edges and to determine the bore centre-points to the lath spindle.When there is contact between the feeler head and the workpiece 1 battery (in the shaft) cause the lamp to illuminate if the workpiece, receiver and tool holdingfixture are connected electrically.2DDL1Ident. No. 005-0111 spring ballØ 10.000L1 L1Ident. No. 015-0251 spring ball Ø 10.0002 tracer path approx. 3 mmVersion 2-D 2-D acoustic 3-D 3-D acoustic<strong>Clamping</strong> shank Ø D mm 16 20 20 16 20 20Probe ball Ø mm 10 10 10 10 10 10Repetition precision mm ±0,01 ±0,01 ±0,01 ±0,01 ±0,01 ±0,01Overall length L mm 99 92 119 111 106 131<strong>Clamping</strong> length L 1 mm 35 45 45 35 45 4523923 Ident. No. 005 010 011 015 020 025Unit price E O. R. O. R. O. R. O. R. O. R. O. R.L1h High-precision version available on request.Spare batteries No. 56815 202 page 1385Prod. Gr. 2982011/12547