Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

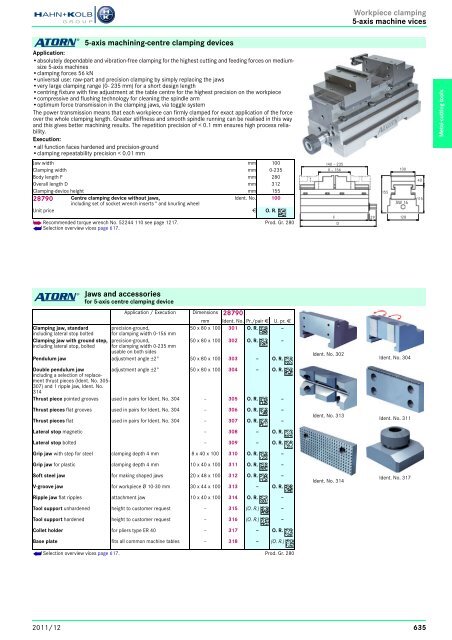

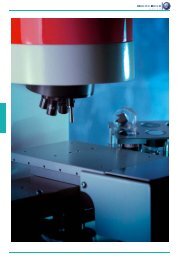

Workpiece clamping5-axis machine vicesContinued next page5-axis machining-centre clamping devicesApplication:•absolutely dependable and vibration-free clamping for the highest cutting and feeding forces on mediumsize5-axis machines•clamping forces 56 kN•universal use: raw-part and precision clamping by simply replacing the jaws•very large clamping range (0- 235 mm) for a short design length•centring fixture with fine adjustment at the table centre for the highest precision on the workpiece•compressive and flushing technology for cleaning the spindle arm•optimum force transmission in the clamping jaws, via toggle systemThe power transmission means that each workpiece can firmly clamped for exact application of the forceover the whole clamping length. Greater stiffness and smooth spindle running can be realised in this wayand this gives better machining results. The repetition precision of < 0.1 mm ensures high process reliability.Execution:•all function faces hardened and precision-ground•clamping repeatability precision < 0.01 mmMetal-cutting toolsJaw width mm 100<strong>Clamping</strong> width mm 0-235Body length F mm 280Overall length D mm 312<strong>Clamping</strong>-device height mm 15528790 Centre clamping device without jaws,Ident. No. 100including set of socket wrench inserts " and knurling wheelUnit price E O. R.h Recommended torque wrench No. 52244 110 see page 1217.i Selection overview vices page 617.Prod. Gr. 280140 – 2350 – 156F 29D155100SW 1612840115Continued next pageJaws and accessoriesfor 5-axis centre clamping deviceApplication / Execution Dimensions 28790mm Ident. No. Pr./pair E U. pr. E<strong>Clamping</strong> jaw, standard precision-ground,50 x 80 x 100 301 O. R. –including lateral stop bolted for clamping width 0-156 mm<strong>Clamping</strong> jaw with ground step, precision-ground,50 x 80 x 100 302 O. R. –including lateral stop, bolted for clamping width 0-235 mmusable on both sidesPendulum jaw adjustment angle ±2° 50 x 80 x 100 303 – O. R.Double pendulum jawadjustment angle ±2° 50 x 80 x 100 304 – O. R.including a selection of replacementthrust pieces (Ident. No. 305-307) and 1 ripple jaw, Ident. No.314Thrust piece pointed grooves used in pairs for Ident. No. 304 – 305 O. R. –Thrust pieces flat grooves used in pairs for Ident. No. 304 – 306 O. R. –Thrust pieces flat used in pairs for Ident. No. 304 – 307 O. R. –Lateral stop magnetic – 308 – O. R.Lateral stop bolted – 309 – O. R.Grip jaw with step for steel clamping depth 4 mm 8 x 40 x 100 310 O. R. –Grip jaw for plastic clamping depth 4 mm 10 x 40 x 100 311 O. R. –Soft steel jaw for making shaped jaws 20 x 48 x 100 312 O. R. –V-groove jaw for workpiece Ø 10-30 mm 30 x 44 x 100 313 – O. R.Ripple jaw flat ripples attachment jaw 10 x 40 x 100 314 O. R. –Tool support unhardened height to customer request – 315 (O. R.) –Tool support hardened height to customer request – 316 (O. R.) –Collet holder for pliers type ER 40 – 317 – O. R.Base plate fits all common machine tables – 318 – (O. R.)Ident. No. 302Ident. No. 313Ident. No. 314Ident. No. 304Ident. No. 311Ident. No. 317i Selection overview vices page 617. Prod. Gr. 2802011/12635