You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

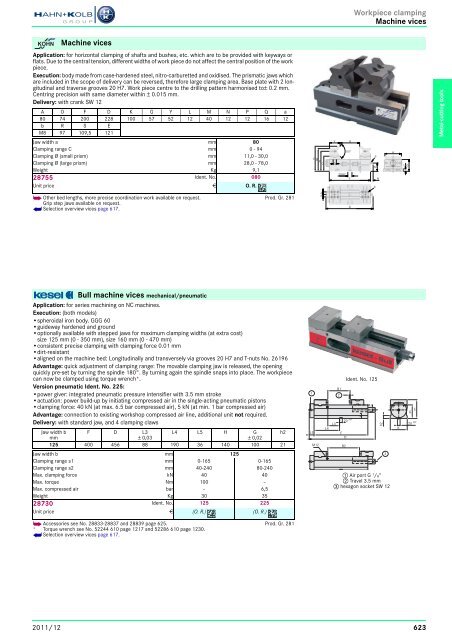

Workpiece clampingMachine vicesContinued next pageMachine vicesApplication: for horizontal clamping of shafts and bushes, etc. which are to be provided with keyways orflats. Due to the central tension, different widths of work piece do not affect the central position of the workpiece.Execution: body made from case-hardened steel, nitro-carburetted and oxidised. The prismatic jaws whichare included in the scope of delivery can be reversed, therefore large clamping area. Base plate with 2 longitudinaland traverse grooves 20 H7. Work piece centre to the drilling pattern harmonised to± 0.2 mm.Centring precision with same diameter within ± 0.015 mm.Delivery: with crank SW 12A O F D K G Y L M N P Q a80 74 200 228 100 57 52 12 40 12 12 16 12b R S EM8 97 109,5 121Metal-cutting toolsJaw width a mm 80<strong>Clamping</strong> range C mm 0 - 94<strong>Clamping</strong> Ø (small prism) mm 11,0 - 30,0<strong>Clamping</strong> Ø (large prism) mm 28,0 - 78,0Weight Kg 9,128755 Ident. No. 080Unit price E O. R.E SROY B110°Q20H7FPMNbAL Gh Other bed lengths, more precise coordination work available on request.Grip step jaws available on request.i Selection overview vices page 617.Prod. Gr. 281aDBull machine vices mechanical/pneumaticApplication: for series machining on NC machines.Execution: (both models)•spheroidal iron body. GGG 60•guideway hardened and ground•optionally available with stepped jaws for maximum clamping widths (at extra cost)size 125 mm (0 - 350 mm), size 160 mm (0 - 470 mm)•consistent precise clamping with clamping force 0.01 mm•dirt-resistant•aligned on the machine bed: Longitudinally and transversely via grooves 20 H7 and T-nuts No. 26196Advantage: quick adjustment of clamping range: The movable clamping jaw is released, the openingquickly pre-set by turning the spindle 180°. By turning again the spindle snaps into place. The workpiececan now be clamped using torque wrench*.Version pneumatic Ident. No. 225:•power giver: integrated pneumatic pressure intensifier with 3.5 mm stroke•actuation: power build-up by initiating compressed air in the single-acting pneumatic pistons•clamping force: 40 kN (at max. 6.5 bar compressed air), 5 kN (at min. 1 bar compressed air)Advantage: connection to existing workshop compressed air line, additional unit not required.Delivery: with standard jaw, and 4 clamping clawsJaw width b F D L3 L4 L5 H G h2mm± 0,03± 0,02125 400 456 88 190 36 140 100 21Jaw width b mm 125<strong>Clamping</strong> range s1 mm 0-165 0-165<strong>Clamping</strong> range s2 mm 40-240 80-240Max. clamping force kN 40 40Max. torque Nm 100 –Max. compressed air bar – 6,5Weight Kg 30 3528730 Ident. No. 125 225Unit price E (O. R.) (O. R.)1L5M12L4L3B12Ident. No. 12520 H7FDB2h21 Air port G 1 / 8"2 Travel 3.5 mm3 hexagon socket SW 123KG E20 H7Continued next pageh Accessories see No. 28833-28837 and 28839 page 625.* Torque wrench see No. 52244 610 page 1217 and 52286 610 page 1230.i Selection overview vices page 617.Prod. Gr. 2812011/12623