Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

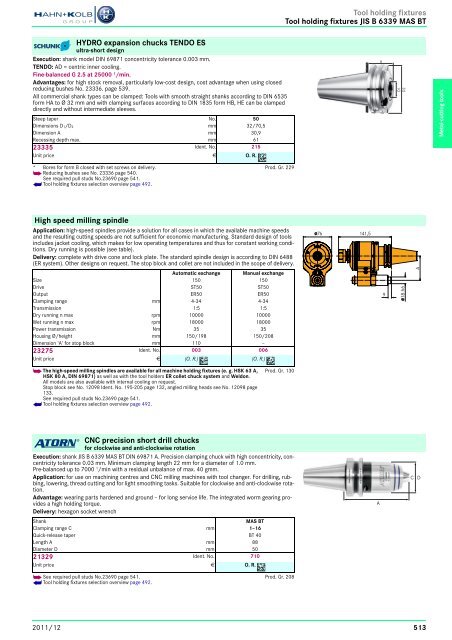

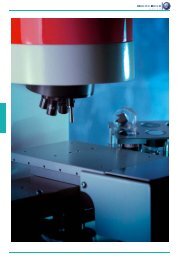

Tool holding fixturesTool holding fixtures JIS B 6339 MAS BTContinued next pageHYDRO expansion chucks T<strong>EN</strong>DO ESultra-short designExecution: shank model DIN 69871 concentricity tolerance 0.003 mm.T<strong>EN</strong>DO: AD = centric inner cooling.Fine-balanced G 2.5 at 25000 1 /min.Advantages: for high stock removal, particularly low-cost design, cost advantage when using closedreducing bushes No. 23336. page 539.All commercial shank types can be clamped: <strong>Tools</strong> with smooth straight shanks according to DIN 6535form HA to Ø 32 mm and with clamping surfaces according to DIN 1835 form HB, HE can be clampeddirectly and without intermediate sleeves.Steep taper No. 50Dimensions D 1/D 2 mm 32/70,5Dimension A mm 30,9Recessing depth max. mm 6123335 Ident. No. 215Unit price E O. R.AD1D2Metal-cutting tools* Bores for form B closed with set screws on delivery.h Reducing bushes see No. 23336 page 540.See required pull studs No.23690 page 541.i Tool holding fixtures selection overview page 492.Prod. Gr. 229Continued next pageHigh speed milling spindleApplication: high-speed spindles provide a solution for all cases in which the available machine speedsand the resulting cutting speeds are not sufficient for economic manufacturing. Standard design of toolsincludes jacket cooling, which makes for low operating temperatures and thus for constant working conditions.Dry running is possible (see table).Delivery: complete with drive cone and lock plate. The standard spindle design is according to DIN 6488(ER system). Other designs on request. The stop block and collet are not included in the scope of delivery.Automatic exchange Manual exchangeSize 150 150Drive ST50 ST50Output ER50 ER50<strong>Clamping</strong> range mm 4-34 4-34Transmission 1:5 1:5Dry running n max rpm 10000 10000Wet running n max rpm 18000 18000Power transmission Nm 35 35Housing Ø/height mm 150/198 150/208Dimension 'A' for stop block mm 110 –23275 Ident. No. 003 006Unit price E (O. R.) (O. R.)76 141,5918 h6Ah The high-speed milling spindles are available for all machine holding fixtures (e. g. HSK 63 A,HSK 80 A, DIN 69871) as well as with the tool holders ER collet chuck system and Weldon.All models are also available with internal cooling on request.Stop block see No. 12098 Ident. No. 195-205 page 132, angled milling heads see No. 12098 page133.See required pull studs No.23690 page 541.i Tool holding fixtures selection overview page 492.Prod. Gr. 130Continued next pageCNC precision short drill chucksfor clockwise and anti-clockwise rotationExecution: shank JIS B 6339 MAS BT DIN 69871 A. Precision clamping chuck with high concentricity, concentricitytolerance 0.03 mm. Minimum clamping length 22 mm for a diameter of 1.0 mm.Pre-balanced up to 7000 1 /min with a residual unbalance of max. 40 gmm.Application: for use on machining centres and CNC milling machines with tool changer. For drilling, rubbing,lowering, thread cutting and for light smoothing tasks. Suitable for clockwise and anti-clockwise rotation.Advantage: wearing parts hardened and ground – for long service life. The integrated worm gearing providesa high holding torque.Delivery: hexagon socket wrenchShankMAS BT<strong>Clamping</strong> range C mm 1–16Quick-release taper BT 40Length A mm 88Diameter D mm 5021329 Ident. No. 710Unit price E O. R.AC Dh See required pull studs No.23690 page 541.i Tool holding fixtures selection overview page 492.Prod. Gr. 2082011/12513