Magnetic clamping technologyPermanent-magnet magnetic round chucksContinued next pagePermanent-magnet magnetic round chucks NEOMICROwith parallel pole pitchApplication: for grinding and eroding work.Execution:The micro-pole division of this magnetic clamping plate makes it possible to clamp very thin and smallitems. Furthermore, the round chuck is based on neodymium-magnet clamping-system technology forhigher clamping power. The holding force can be adjusted thereby making it easier to align the workpiece.Advantages:•compact construction and hence low weight•nominal holding power 80 N/cm²•pole plate available with holes for driving pins and centring aids<strong>Clamping</strong> plates Ø A mm 100 150 200 250 300Height h mm 50 50 52 52 54Centre Ø B (H7) mm 60 110 160 200 250Centring depth C mm 4 4 4 4 4Centring bore D/F (if requested) mm 20 x 14 20 x 14 22 x 16 22 x 16 22 x 18Hole circle Ø E (for fastening) mm 80 130 180 230 280Fastening holes M8 M8 M10 M10 M12Magnetic active length L mm 77 117 169 213 265Pole pitch St/Nf mm 1,5/0,5 1,5/0,5 1,5/0,5 1,5/0,5 1,5/0,5Wearing thickness mm 5 5 5 5 5Weight Kg 3 7 12 19 2824366 Ident. No. 100 150 200 250 300Unit price E (O. R.) (O. R.) (O. R.) (O. R.) (O. R.)MALDBEF28 HCMetal-cutting toolsProd. Gr. 230Continued next pagePermanent-magnet magnetic round chucks FERROMAXwith parallel pole pitchApplication: for lathes and grinding machines, dividing and tracer divider devices.Execution: suited for clamping of plates, double and reinforced ceramic magnetic system, max. clampingforce from a work piece thickness of 8 mm, magnetic field height 8 mm, integrated, concentric groove facilitatethe centring of the work piece, holes or profiles up to a depth of 6 mm can be integrated into theclamping surface, up to 22 mm can be integrated into the steel poles, in the centre, a centring bore hole ispossible, max. depth 22 mm, max. Ø 22 mm, at Ø 200-400 mm - adhesive force infinitely variable.Delivery: with chuck key<strong>Clamping</strong> plates Ø A mm 200 250 300 350 400Height h mm 78 78 78 78 78Centre Ø B H 7 mm 150 200 250 300 300Centring depth C mm 4,5 4,5 4,5 4,5 4,5Centring bore D/F (if requested) mm 22 22 22 22 22Hole circle Ø E for fastening mm 182 232 285 334 375Fastening holes M 4xM8 4xM8 4xM8 4xM8 6xM10Magnetic active length L mm 173 199 238 290 323Pole pitch St/Nf mm 8/5 8/5 12/5 12/5 12/5Height pole flange mm 28 28 28 28 28Of which wearing mm 8 8 8 8 8Switching points Number 1 1 1 1 1Weight Kg 12 17 27 40 5624370 Ident. No. 200 250 300 350d 400dUnit price E O. R. O. R. O. R. (O. R.) (O. R.)d = Delivered ex works, postage and packaging excluded.h Other sizes up to Ø 800 mm available on request.Prod. Gr. 230Continued next pagePermanent-magnet magnetic round chucks NEOSTARwith radial pole pitchApplication: for lathes and grinding machines.Execution: suitable for clamping annular work pieces, high clamping force due to neodymium magneticsystem, balanced design, suitable for high speeds, adhesive force infinitely adjustable, a through-bore 'C'can be made in the centre.<strong>Clamping</strong> plates Ø A mm 150 200 250 300 350 400Centre Ø D h7 mm 50 60 80 150 170 200Magnet-free Zone B mm 20 28 30 40 40 40Through-bore max. C mm 24 30 50 58 58 58Hole circle E/F mm 80/120 110/180 140/220 180/260 220/300 260/340Fastening holes M/P 8 x M6/8 8 x M6/8 8 x M6/8 8 x M8/10 8 x M8/12 8 x M8/12Height h mm 57 57 70 73 73 75Height pole flange mm 18 18 18 18 18 18Of which wearing mm 7 7 7 7 7 7Number of poles 10 12 16 16 20 20Weight Kg 8 14 27 41 55 7524376 Ident. No. 150 200 250 300d 350d 400dUnit price E O. R. O. R. O. R. (O. R.) (O. R.) (O. R.)d = Delivered ex works, postage and packaging excluded.h Other sizes up to Ø 800 mm available on request.Supporting plates see page 586.Prod. Gr. 230PGC max.BDEFAMH2011/12585

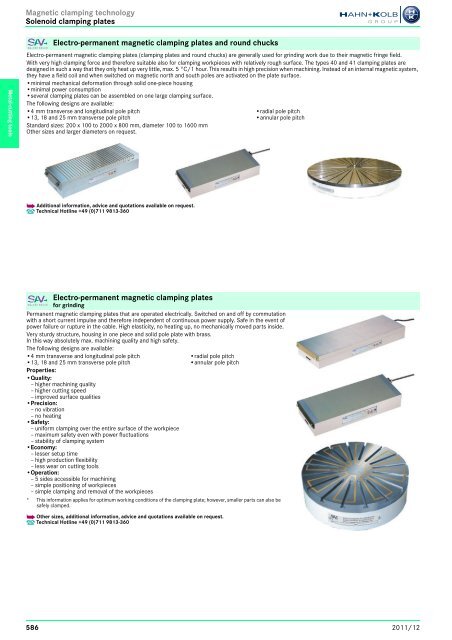

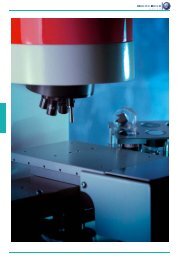

Magnetic clamping technologySolenoid clamping platesMetal-cutting toolsContinued next pageElectro-permanent magnetic clamping plates and round chucksElectro-permanent magnetic clamping plates (clamping plates and round chucks) are generally used for grinding work due to their magnetic fringe field.With very high clamping force and therefore suitable also for clamping workpieces with relatively rough surface. The types 40 and 41 clamping plates aredesigned in such a way that they only heat up very little, max. 5 °C/1 hour. This results in high precision when machining. Instead of an internal magnetic system,they have a field coil and when switched on magnetic north and south poles are activated on the plate surface.•minimal mechanical deformation through solid one-piece housing•minimal power consumption•several clamping plates can be assembled on one large clamping surface.The following designs are available:•4 mm transverse and longitudinal pole pitch•13, 18 and 25 mm transverse pole pitchStandard sizes: 200 x 100 to 2000 x 800 mm, diameter 100 to 1600 mmOther sizes and larger diameters on request.•radial pole pitch•annular pole pitchh Additional information, advice and quotations available on request.t Technical Hotline +49 (0)711 9813-360Continued next pageElectro-permanent magnetic clamping platesfor grindingPermanent magnetic clamping plates that are operated electrically. Switched on and off by commutationwith a short current impulse and therefore independent of continuous power supply. Safe in the event ofpower failure or rupture in the cable. High elasticity, no heating up, no mechanically moved parts inside.Very sturdy structure, housing in one piece and solid pole plate with brass.In this way absolutely max. machining quality and high safety.The following designs are available:•4 mm transverse and longitudinal pole pitch•13, 18 and 25 mm transverse pole pitch•radial pole pitch•annular pole pitchProperties:•Quality:– higher machining quality– higher cutting speed– improved surface qualities•Precision:– no vibration– no heating•Safety:– uniform clamping over the entire surface of the workpiece– maximum safety even with power fluctuations– stability of clamping system•Economy:– lesser setup time– high production flexibility–less wear on cutting tools•Operation:– 5 sides accessible for machining– simple positioning of workpieces– simple clamping and removal of the workpieces* This information applies for optimum working conditions of the clamping plate; however, smaller parts can also besafely clamped.h Other sizes, additional information, advice and quotations available on request.t Technical Hotline +49 (0)711 9813-360586 2011/12