You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

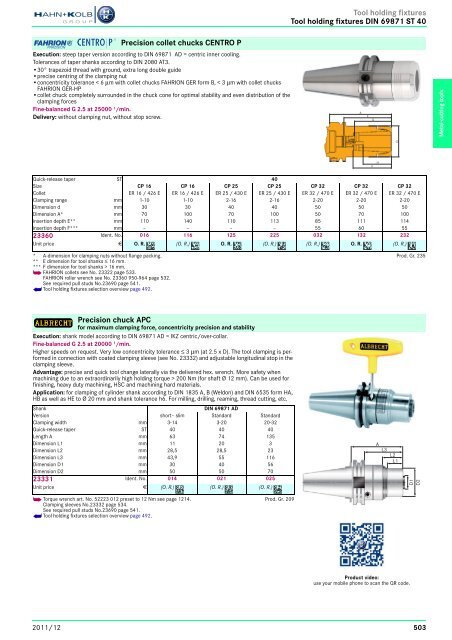

Tool holding fixturesTool holding fixtures DIN 69871 ST 40Continued next pagePrecision collet chucks C<strong>EN</strong>TRO PExecution: steep taper version according to DIN 69871 AD = centric inner cooling.Tolerances of taper shanks according to DIN 2080 AT3.•30° trapezoid thread with ground, extra long double guide•precise centring of the clamping nut•concentricity tolerance < 6 μm with collet chucks FAHRION GER form B, < 3 μm with collet chucksFAHRION GER-HP•collet chuck completely surrounded in the chuck cone for optimal stability and even distribution of theclamping forcesFine-balanced G 2.5 at 25000 1 /min.Delivery: without clamping nut, without stop screw.AEGDMetal-cutting toolsFHQuick-release taper ST 40Size CP 16 CP 16 CP 25 CP 25 CP 32 CP 32 CP 32Collet ER 16 / 426 E ER 16 / 426 E ER 25 / 430 E ER 25 / 430 E ER 32 / 470 E ER 32 / 470 E ER 32 / 470 E<strong>Clamping</strong> range mm 1-10 1-10 2-16 2-16 2-20 2-20 2-20Dimension d mm 30 30 40 40 50 50 50Dimension A* mm 70 100 70 100 50 70 100insertion depth E** mm 110 140 110 113 85 111 114insertion depth F*** mm – – – – 55 60 5523360 Ident. No. 016 116 125 225 032 132 232Unit price E O. R. (O. R.) O. R. (O. R.) (O. R.) O. R. (O. R.)* A-dimension for clamping nuts without flange packing.** E dimension for tool shanks ≤ 16 mm.*** F dimension for tool shanks > 16 mm.h FAHRION collets see No. 23322 page 533.FAHRION roller wrench see No. 23360 950-964 page 532.See required pull studs No.23690 page 541.i Tool holding fixtures selection overview page 492.Prod. Gr. 235Continued next pagePrecision chuck APCfor maximum clamping force, concentricity precision and stabilityExecution: shank model according to DIN 69871 AD = IKZ centric/over-collar.Fine-balanced G 2.5 at 20000 1 /min.Higher speeds on request. Very low concentricity tolerance ≤ 3 μm (at 2.5 x D). The tool clamping is performedin connection with coated clamping sleeve (see No. 23332) and adjustable longitudinal stop in theclamping sleeve.Advantage: precise and quick tool change laterally via the delivered hex. wrench. More safety whenmachining due to an extraordinarily high holding torque > 200 Nm (for shaft Ø 12 mm). Can be used forfinishing, heavy duty machining, HSC and machining hard materials.Application: for clamping of cylinder shank according to DIN 1835 A, B (Weldon) and DIN 6535 form HA,HB as well as HE to Ø 20 mm and shank tolerance h6. For milling, drilling, reaming, thread cutting, etc.ShankDIN 69871 ADVersion short– slim Standard Standard<strong>Clamping</strong> width mm 3-14 3-20 20-32Quick-release taper ST 40 40 40Length A mm 63 74 135Dimension L1 mm 11 20 3Dimension L2 mm 28,5 28,5 23Dimension L3 mm 43,9 55 116Dimension D1 mm 30 40 56Dimension D2 mm 50 50 7023331 Ident. No. 014 021 025Unit price E (O. R.) (O. R.) (O. R.)AL3L2L1D1D2h Torque wrench art. No. 52223 012 preset to 12 Nm see page 1214.<strong>Clamping</strong> sleeves No.23332 page 534.See required pull studs No.23690 page 541.i Tool holding fixtures selection overview page 492.Prod. Gr. 209Product video:use your mobile phone to scan the QR code.2011/12503