CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

High Performance Minipump<br />

N. Schmid, T. Burch, P. Schmid, H. F. Knapp, J. Auerswald, S. Berchtold<br />

A high performance bidirectional minipump is being developed with a width of only 8 mm <strong>and</strong> a mass of only 7 g including motor.<br />

A variety of pumps can be used for metering purposes such<br />

as syringe pumps, piston pumps, peristaltic pumps, gearwheel<br />

pumps <strong>and</strong> diaphragm pumps. However, only some are<br />

available in a small size configuration. Most of these small<br />

pumps operate with diaphragms or gearwheels. But even<br />

these pumps can still be relatively bulky <strong>and</strong> heavy <strong>and</strong> in<br />

particular diaphragm pumps offer neither continuous flow nor<br />

are they pulsation free.<br />

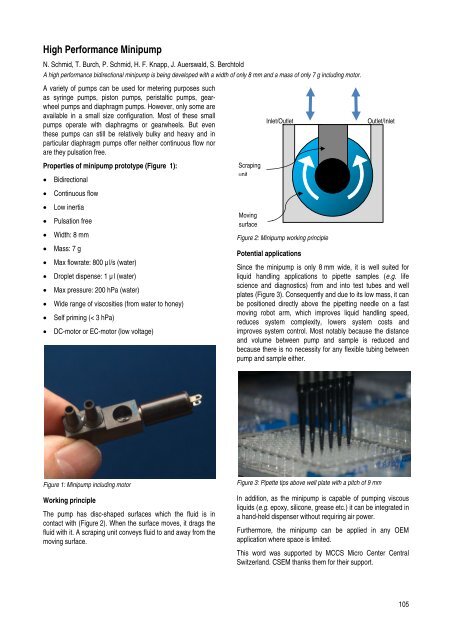

Properties of minipump prototype (Figure 1):<br />

• Bidirectional<br />

• Continuous flow<br />

• Low inertia<br />

• Pulsation free<br />

• Width: 8 mm<br />

• Mass: 7 g<br />

• Max flowrate: 800 µl/s (water)<br />

• Droplet dispense: 1 µl (water)<br />

• Max pressure: 200 hPa (water)<br />

• Wide range of viscosities (from water to honey)<br />

• Self priming (< 3 hPa)<br />

• DC-motor or EC-motor (low voltage)<br />

Figure 1: Minipump including motor<br />

Working principle<br />

The pump has disc-shaped surfaces which the fluid is in<br />

contact with (Figure 2). When the surface moves, it drags the<br />

fluid with it. A scraping unit conveys fluid to <strong>and</strong> away from the<br />

moving surface.<br />

Scraping<br />

unit<br />

Moving<br />

surface<br />

Inlet/Outlet Outlet/Inlet<br />

Figure 2: Minipump working principle<br />

Potential applications<br />

Since the minipump is only 8 mm wide, it is well suited for<br />

liquid h<strong>and</strong>ling applications to pipette samples (e.g. life<br />

science <strong>and</strong> diagnostics) from <strong>and</strong> into test tubes <strong>and</strong> well<br />

plates (Figure 3). Consequently <strong>and</strong> due to its low mass, it can<br />

be positioned directly above the pipetting needle on a fast<br />

moving robot arm, which improves liquid h<strong>and</strong>ling speed,<br />

reduces system complexity, lowers system costs <strong>and</strong><br />

improves system control. Most notably because the distance<br />

<strong>and</strong> volume between pump <strong>and</strong> sample is reduced <strong>and</strong><br />

because there is no necessity for any flexible tubing between<br />

pump <strong>and</strong> sample either.<br />

Figure 3: Pipette tips above well plate with a pitch of 9 mm<br />

In addition, as the minipump is capable of pumping viscous<br />

liquids (e.g. epoxy, silicone, grease etc.) it can be integrated in<br />

a h<strong>and</strong>-held dispenser without requiring air power.<br />

Furthermore, the minipump can be applied in any OEM<br />

application where space is limited.<br />

This word was supported by MCCS Micro Center Central<br />

Switzerl<strong>and</strong>. <strong>CSEM</strong> thanks them for their support.<br />

105