CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Silicon Nanostructuring for Controlling Surface Wettability<br />

N. Blondiaux, E. Scolan, A.-M. Popa, J. Gavillet • , R. Pugin<br />

<strong>CSEM</strong> reports on the fabrication of sub-micrometer silicon pillars with controlled aspect ratios by combining thin polymer film structuring <strong>and</strong> dry<br />

etching. The structures were used to create superhydrophobic surfaces. Depending on the aspect ratio of the pillars, different superhydrophobic<br />

wetting states were observed. Above a certain aspect ratio, the resulting surfaces have particularly good self-cleaning properties.<br />

The effect of surface roughness on wettability has received<br />

increasing research interest during the last decade. An<br />

accurate control of surface topography can indeed<br />

dramatically enhance the wetting properties [1] . Depending on<br />

their surface chemistry, rough surfaces will become either<br />

“superhydrophilic” or “superhydrophobic”. From a<br />

technological point of view, many potential applications of<br />

these effects have been demonstrated. Superhydrophilic<br />

surfaces are for instance being used for their anti-fogging<br />

properties while super-hydrophobic surfaces are interesting<br />

for their outst<strong>and</strong>ing self-cleaning properties. The most wellknown<br />

example to illustrate the latter effect is found in nature<br />

with lotus leaves which present very intricate surface micro<br />

<strong>and</strong> nanostructures.<br />

The objective of this work is to create superhydrophobic<br />

silicon surfaces by both surface structuring <strong>and</strong> surface<br />

functionalization. The dimensions of the structures have been<br />

systematically varied in order to investigate the effect of<br />

topography on wettability.<br />

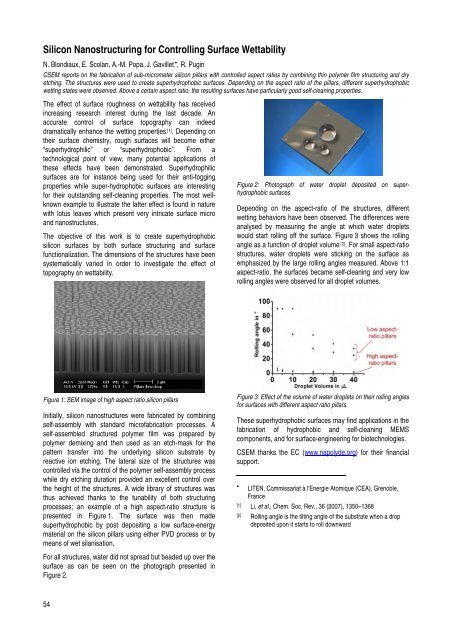

Figure 1: SEM image of high aspect ratio silicon pillars<br />

Initially, silicon nanostructures were fabricated by combining<br />

self-assembly with st<strong>and</strong>ard microfabrication processes. A<br />

self-assembled structured polymer film was prepared by<br />

polymer demixing <strong>and</strong> then used as an etch-mask for the<br />

pattern transfer into the underlying silicon substrate by<br />

reactive ion etching. The lateral size of the structures was<br />

controlled via the control of the polymer self-assembly process<br />

while dry etching duration provided an excellent control over<br />

the height of the structures. A wide library of structures was<br />

thus achieved thanks to the tunability of both structuring<br />

processes; an example of a high aspect-ratio structure is<br />

presented in Figure 1. The surface was then made<br />

superhydrophobic by post depositing a low surface-energy<br />

material on the silicon pillars using either PVD process or by<br />

means of wet silanisation.<br />

For all structures, water did not spread but beaded up over the<br />

surface as can be seen on the photograph presented in<br />

Figure 2.<br />

54<br />

Figure 2: Photograph of water droplet deposited on superhydrophobic<br />

surfaces<br />

Depending on the aspect-ratio of the structures, different<br />

wetting behaviors have been observed. The differences were<br />

analysed by measuring the angle at which water droplets<br />

would start rolling off the surface. Figure 3 shows the rolling<br />

angle as a function of droplet volume [2] . For small aspect-ratio<br />

structures, water droplets were sticking on the surface as<br />

emphasized by the large rolling angles measured. Above 1:1<br />

aspect-ratio, the surfaces became self-cleaning <strong>and</strong> very low<br />

rolling angles were observed for all droplet volumes.<br />

Figure 3: Effect of the volume of water droplets on their rolling angles<br />

for surfaces with different aspect ratio pillars<br />

These superhydrophobic surfaces may find applications in the<br />

fabrication of hydrophobic <strong>and</strong> self-cleaning MEMS<br />

components, <strong>and</strong> for surface-engineering for biotechnologies.<br />

<strong>CSEM</strong> thanks the EC (www.napolyde.org) for their financial<br />

support.<br />

•<br />

LITEN, Commissariat à l'Energie Atomique (CEA), Grenoble,<br />

France<br />

[1] Li, et al., Chem. Soc. Rev., 36 (2007), 1350–1368<br />

[2] Rolling angle is the tilting angle of the substrate when a drop<br />

deposited upon it starts to roll downward