CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Laser Flow Meter<br />

C. Verjus, P. Renevey, V. Neuman, J.-A. Porchet<br />

<strong>CSEM</strong> has developed together with its industrial partner DIGMESA AG [1] an innovative, non-intrusive flow measurement sensor system. In the<br />

designed prototype, the liquid flows through a straight glass tube of 4 mm internal diameter, well adapted for a nominal range of a few milliliters per<br />

minute. The measurement is based on an optical measurement technique, keeping the response time in the order of a dozen milliseconds.<br />

<strong>Technical</strong> st<strong>and</strong>ards of today for flow sensors require to be<br />

non-invasive. For the h<strong>and</strong>lings of liquids in the chemistry,<br />

food or semiconductor industries, measurements are to be<br />

performed through a straight tube to allow easy cleaning along<br />

with preventing pollution of the fluid or sensor damage.<br />

Large flows can easily be monitored non-invasively, for<br />

instance with ultrasonic devices. Low flows are more critical,<br />

particularly if the fluid does not contain particles to take<br />

advantage of the Doppler effect. Today commercially available<br />

solutions to measure flows of liquids in the millilitre per minute<br />

range are based on the thermal mass measurement principle,<br />

where the flow influences the temperature distribution up- <strong>and</strong><br />

downstream from a heating resistor. Drawbacks include a long<br />

response time <strong>and</strong> media dependency.<br />

A small-sized Swiss company, Digmesa AG [1] , developing <strong>and</strong><br />

manufacturing flow meters for over 25 years, entrusted <strong>CSEM</strong><br />

with the development of an innovative, non-intrusive sensing<br />

technology, able to measure flows in the 1-20 ml/min range.<br />

Subsequently, a new flow measurement principle has been<br />

developed <strong>and</strong> patented, involving only a laser beam crossing<br />

the straight glass tube where the media is flowing. A sensor<br />

based on this technology has been designed. Prototypes have<br />

been built to demonstrate the method, with glass tubes with<br />

an inside diameter of 4 mm as well as 0.5 mm.<br />

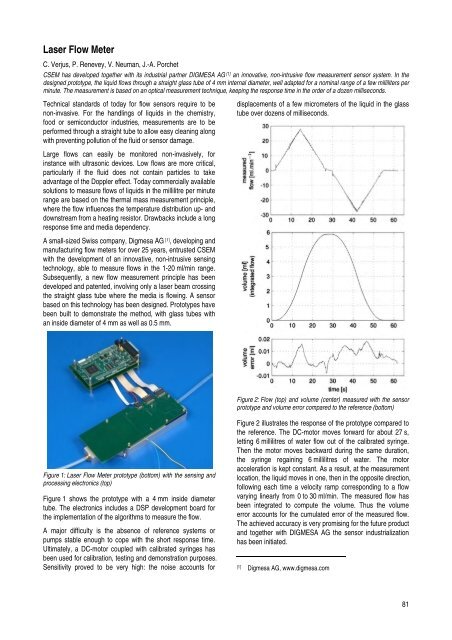

Figure 1: Laser Flow Meter prototype (bottom) with the sensing <strong>and</strong><br />

processing electronics (top)<br />

Figure 1 shows the prototype with a 4 mm inside diameter<br />

tube. The electronics includes a DSP development board for<br />

the implementation of the algorithms to measure the flow.<br />

A major difficulty is the absence of reference systems or<br />

pumps stable enough to cope with the short response time.<br />

Ultimately, a DC-motor coupled with calibrated syringes has<br />

been used for calibration, testing <strong>and</strong> demonstration purposes.<br />

Sensitivity proved to be very high: the noise accounts for<br />

displacements of a few micrometers of the liquid in the glass<br />

tube over dozens of milliseconds.<br />

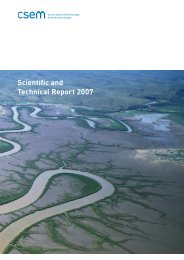

Figure 2: Flow (top) <strong>and</strong> volume (center) measured with the sensor<br />

prototype <strong>and</strong> volume error compared to the reference (bottom)<br />

Figure 2 illustrates the response of the prototype compared to<br />

the reference. The DC-motor moves forward for about 27 s,<br />

letting 6 millilitres of water flow out of the calibrated syringe.<br />

Then the motor moves backward during the same duration,<br />

the syringe regaining 6 millilitres of water. The motor<br />

acceleration is kept constant. As a result, at the measurement<br />

location, the liquid moves in one, then in the opposite direction,<br />

following each time a velocity ramp corresponding to a flow<br />

varying linearly from 0 to 30 ml/min. The measured flow has<br />

been integrated to compute the volume. Thus the volume<br />

error accounts for the cumulated error of the measured flow.<br />

The achieved accuracy is very promising for the future product<br />

<strong>and</strong> together with DIGMESA AG the sensor industrialization<br />

has been initiated.<br />

[1] Digmesa AG, www.digmesa.com<br />

81