CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

CSEM Scientific and Technical Report 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Batch Fabrication of Ultrathin Nanoporous Membranes<br />

A.-M. Popa, P. Niedermann, R. Pugin<br />

Block-copolymer assisted nanostructuring has been successfully employed for the definition of densely packed nanopores with a mean diameter of<br />

80 nm in silicon nitride thin films with a thickness of 100 nm. The release of these films by st<strong>and</strong>ard microfabrication techniques leads to suspended<br />

nanoporous membranes with areas ranging from 100 to 16000 μm 2 .<br />

Nanoporous membranes are essential components in<br />

ultrafiltration, sensing <strong>and</strong> “smart” cell-culture devices. Most<br />

available systems, however, display poor chemical <strong>and</strong><br />

mechanical stability, broad pore size distribution, <strong>and</strong> a high<br />

aspect ratio of the nanopores (1:1000). These properties<br />

result in fast membrane degradation, poor molecular cut-off,<br />

important material losses, <strong>and</strong> long response times. In order<br />

to overcome these drawbacks <strong>CSEM</strong> has recently developed<br />

processes for the fabrication of mechanically stable ultrathin<br />

silicon nitride membranes with extremely narrow pore size<br />

distribution <strong>and</strong> nanopore aspect ratio close to 1:1 (Figure 1).<br />

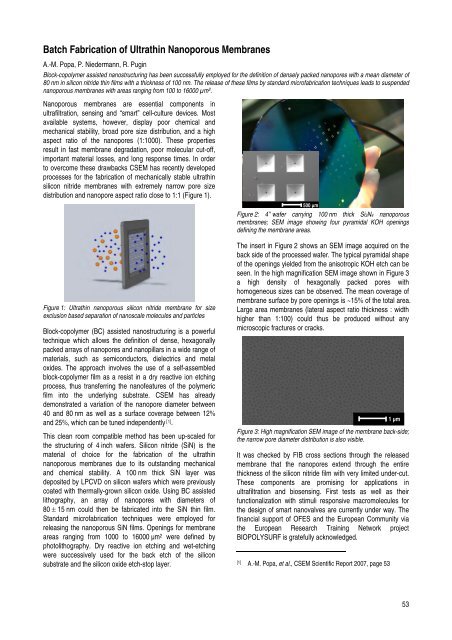

Figure 1: Ultrathin nanoporous silicon nitride membrane for size<br />

exclusion based separation of nanoscale molecules <strong>and</strong> particles<br />

Block-copolymer (BC) assisted nanostructuring is a powerful<br />

technique which allows the definition of dense, hexagonally<br />

packed arrays of nanopores <strong>and</strong> nanopillars in a wide range of<br />

materials, such as semiconductors, dielectrics <strong>and</strong> metal<br />

oxides. The approach involves the use of a self-assembled<br />

block-copolymer film as a resist in a dry reactive ion etching<br />

process, thus transferring the nanofeatures of the polymeric<br />

film into the underlying substrate. <strong>CSEM</strong> has already<br />

demonstrated a variation of the nanopore diameter between<br />

40 <strong>and</strong> 80 nm as well as a surface coverage between 12%<br />

<strong>and</strong> 25%, which can be tuned independently [1] .<br />

This clean room compatible method has been up-scaled for<br />

the structuring of 4 inch wafers. Silicon nitride (SiN) is the<br />

material of choice for the fabrication of the ultrathin<br />

nanoporous membranes due to its outst<strong>and</strong>ing mechanical<br />

<strong>and</strong> chemical stability. A 100 nm thick SiN layer was<br />

deposited by LPCVD on silicon wafers which were previously<br />

coated with thermally-grown silicon oxide. Using BC assisted<br />

lithography, an array of nanopores with diameters of<br />

80 ± 15 nm could then be fabricated into the SiN thin film.<br />

St<strong>and</strong>ard microfabrication techniques were employed for<br />

releasing the nanoporous SiN films. Openings for membrane<br />

areas ranging from 1000 to 16000 μm 2 were defined by<br />

photolithography. Dry reactive ion etching <strong>and</strong> wet-etching<br />

were successively used for the back etch of the silicon<br />

substrate <strong>and</strong> the silicon oxide etch-stop layer.<br />

500 μm<br />

Figure 2: 4’’ wafer carrying 100 nm thick Si3N4 nanoporous<br />

membranes; SEM image showing four pyramidal KOH openings<br />

defining the membrane areas.<br />

The insert in Figure 2 shows an SEM image acquired on the<br />

back side of the processed wafer. The typical pyramidal shape<br />

of the openings yielded from the anisotropic KOH etch can be<br />

seen. In the high magnification SEM image shown in Figure 3<br />

a high density of hexagonally packed pores with<br />

homogeneous sizes can be observed. The mean coverage of<br />

membrane surface by pore openings is ~15% of the total area.<br />

Large area membranes (lateral aspect ratio thickness : width<br />

higher than 1:100) could thus be produced without any<br />

microscopic fractures or cracks.<br />

Figure 3: High magnification SEM image of the membrane back-side;<br />

the narrow pore diameter distribution is also visible.<br />

It was checked by FIB cross sections through the released<br />

membrane that the nanopores extend through the entire<br />

thickness of the silicon nitride film with very limited under-cut.<br />

These components are promising for applications in<br />

ultrafiltration <strong>and</strong> biosensing. First tests as well as their<br />

functionalization with stimuli responsive macromolecules for<br />

the design of smart nanovalves are currently under way. The<br />

financial support of OFES <strong>and</strong> the European Community via<br />

the European Research Training Network project<br />

BIOPOLYSURF is gratefully acknowledged.<br />

[1] A.-M. Popa, et al., <strong>CSEM</strong> <strong>Scientific</strong> <strong>Report</strong> 2007, page 53<br />

1 μm<br />

53