- Page 1 and 2:

AN ABSTRACT OF A DISSERTAION AN INV

- Page 3 and 4:

coupling and interaction terms are

- Page 5 and 6:

CERTIFICATE OF APPROVAL OF DISSERTA

- Page 7 and 8:

ACKNOWLEDGEMENTS I would like to ex

- Page 9 and 10:

vi Page 2.2 Machine Design I.......

- Page 11 and 12:

viii Page 4.2.3 Self Inductances of

- Page 13 and 14:

x Page 7.3.4 f = 30 Hz and f = 95 H

- Page 15 and 16:

xii Page 10.8 D-decomposition Metho

- Page 17 and 18:

LIST OF FIGURES xiv Page Figure 1.1

- Page 19 and 20:

Figure 3.10 The simulation of the s

- Page 21 and 22:

Figure 3.34 Measured flux densities

- Page 23 and 24:

xx Page Figure 4.8 Self-inductance

- Page 25 and 26:

Figure 5.2. Simulation results for

- Page 27 and 28:

Figure 6.8. The dynamic response of

- Page 29 and 30:

Figure 7.22. Copper losses of the m

- Page 31 and 32:

Figure 8.7. The dynamic response of

- Page 33 and 34:

Figure 9.4 Steady state analysis, (

- Page 35 and 36:

Figure 9.12. The steady state wavef

- Page 37 and 38:

xxxiv Page Figure 10.16 Pole-zero m

- Page 39 and 40:

Figure 11.2 Per phase equivalent ci

- Page 41 and 42:

CHAPTER 1 INTRODUCTION AND LITERATU

- Page 43 and 44:

The last is the recently developed

- Page 45 and 46:

It should be noted that at any time

- Page 47 and 48:

A. R. Munoz and T.A. Lipo are pione

- Page 49 and 50:

has to be modified to adapt to thes

- Page 51 and 52:

circuit model of an induction machi

- Page 53 and 54:

ωr stator rotor 13 ωr rotor (a) (

- Page 55 and 56:

1.2.4 Field Analysis Method In [5.1

- Page 57 and 58:

separated dc source, etc. From the

- Page 59 and 60:

in [8.14]. In [8.15-8.17], the stud

- Page 61 and 62:

[8.22] and the total losses of the

- Page 63 and 64:

proposed. The switching frequency i

- Page 65 and 66:

The actual rotor mechanical speed i

- Page 67 and 68:

1.2.9 Induction Machine Drive---Vec

- Page 69 and 70:

stator windings were used as flux s

- Page 71 and 72:

The rotor flux can be obtained by:

- Page 73 and 74:

The basic idea of a closed loop flu

- Page 75 and 76:

estimation. It has been claimed in

- Page 77 and 78:

{ k [ ˆ* ( i iˆ ) ] ( k) [ ˆ* Im

- Page 79 and 80:

integral and a new stretch-turn ope

- Page 81 and 82:

The most recent overview paper is g

- Page 83 and 84:

CHAPTER 2 DUAL STATOR WINDING INDUC

- Page 85 and 86:

Table 2.1 Parameters of machine des

- Page 87 and 88:

A C B 2.2.2 Air Gap Flux Density X

- Page 89 and 90:

where, ω s1 and s2 respectively.

- Page 91 and 92:

There are two unknown variables in

- Page 93 and 94:

Since small machines typically have

- Page 95 and 96:

N s E = (2.18) 4. 44 fK φ 1 m Flux

- Page 97 and 98:

conduct away the heat produced in t

- Page 99 and 100:

k cs τ s = 2 2b ⎪ ⎧ ⎡ ⎤⎪

- Page 101 and 102:

are: Fts = H ts( ave) d s ( ave) =

- Page 103 and 104:

1 2 1 = H o ( ) + H o ( ) + H cr 90

- Page 105 and 106:

The skew of the stator winding is n

- Page 107 and 108:

0 bs Figure 2.5. Detailed stator sl

- Page 109 and 110:

y: The pole pitch at the mid point

- Page 111 and 112:

L lsk = L m ( α 2) ⎪⎧ ⎡sin

- Page 113 and 114:

2.3.4 Rotor Bar Resistance r b The

- Page 115 and 116:

2.3.7 Rotor Resistance Referred to

- Page 117 and 118:

Substituting δ = π into (2.97) an

- Page 119 and 120:

atio also increases. The air gap fl

- Page 121 and 122:

From (2.105-2.108), the ratio of th

- Page 123 and 124:

2.5 Conclusions In this chapter, a

- Page 125 and 126:

A recently developed dual stator wi

- Page 127 and 128:

stator winding induction machine ba

- Page 129 and 130:

∫ H ⋅ dl = ∫ J ⋅ ds = N ⋅

- Page 131 and 132:

theory itself is correct. The inacc

- Page 133 and 134:

( θ ) ⋅ g( θ, θ ) − H ( 0)

- Page 135 and 136:

where ( θ ) n A is the average of

- Page 137 and 138:

Since the definition of the mutual

- Page 139 and 140:

3Cs1 Cs1 − Cs1 − 3Cs1 6Cs1 4Cs1

- Page 141 and 142:

3.4.2 Mutual Inductances of the ABC

- Page 143 and 144:

where, ( θ ) n is the average of t

- Page 145 and 146:

1 0 α 1 − r 2π α − r 2π Fig

- Page 147 and 148:

When the skewing factor of the roto

- Page 149 and 150:

3.6 Calculation of Stator-Rotor Mut

- Page 151 and 152:

dλ v = R ⋅ i + (3.58) dt where,

- Page 153 and 154:

3.7.1.3 Stator flux linkage in ABC

- Page 155 and 156:

where, r R is the resistance matrix

- Page 157 and 158:

Only terms in equation (3.77) which

- Page 159 and 160:

119 ( ) ⎥ ⎥ ⎥ ⎥ ⎥ ⎥ ⎥

- Page 161 and 162:

−1 −1 −1 where, λ qdr = Tr L

- Page 163 and 164:

3.16 and Figure 3.17. It is found f

- Page 165 and 166:

Figure 3.11 The simulation of the d

- Page 167 and 168:

Figure 3.14 The simulation of the s

- Page 169 and 170:

Figure 3.16 Rotor bar currents duri

- Page 171 and 172:

Phase Y Figure 3.20 Air gap flux de

- Page 173 and 174:

Figure 3.24 Total air gap flux dens

- Page 175 and 176:

Figure 3.27 The air gap flux densit

- Page 177 and 178:

Figure 3.29 Air gap flux density co

- Page 179 and 180:

Figure 3.33 Air gap flux density in

- Page 181 and 182:

All the waveforms shown above are t

- Page 183 and 184:

Figure 3.39 Air gap flux density pr

- Page 185 and 186:

Figure 3.42 Normalized spectrum of

- Page 187 and 188:

Figure 3.46 Normalized spectrum of

- Page 189 and 190:

Figure 3.49 Normalized spectrum of

- Page 191 and 192:

Figure 3.53 Normalized spectrum of

- Page 193 and 194:

CHAPTER 4 FULL MODEL SIMULATION OF

- Page 195 and 196:

Substituting (3.28) and (3.29) into

- Page 197 and 198:

Figure 4.3 Self-inductance under 20

- Page 199 and 200:

Figure 4.4 Mutual inductance under

- Page 201 and 202:

that L AB = L BA , L BC = L CB and

- Page 203 and 204:

Figure 4.8 Self-inductance under 10

- Page 205 and 206:

Figure 4.10 Mutual inductance under

- Page 207 and 208:

the assumption that the rotor skew

- Page 209 and 210:

Figure 4.15 Self-inductance under 2

- Page 211 and 212:

Figure 4.17 Mutual inductance under

- Page 213 and 214:

Figure 4.19 Mutual inductance under

- Page 215 and 216:

4.4 Mutual Inductances Calculation

- Page 217 and 218:

Figure 4.24 Stator rotor mutual ind

- Page 219 and 220:

Figure 4.25 Stator rotor mutual ind

- Page 221 and 222:

varying inductances excited by four

- Page 223 and 224:

Equations similar to (4.15-4.16) we

- Page 225 and 226:

the number of poles for the winding

- Page 227 and 228:

Figure 4.29 Dynamic response of dua

- Page 229 and 230:

(a) (b) (c) (d) Figure 4.32. Normal

- Page 231 and 232:

CHAPTER 5 FIELD ANALYSIS OF DUAL ST

- Page 233 and 234:

In the analysis that follows the fu

- Page 235 and 236:

where, C s1 is the number of series

- Page 237 and 238:

θ , ∂B1 µ 0r = ⋅ J1 θ ∂θ

- Page 239 and 240:

C C = k π ⋅ d s2 s2 s2 199 (5.19

- Page 241 and 242:

the XYZ winding set is obtained by

- Page 243 and 244:

u rpi 2π ' k − jk θ −( i−1)

- Page 245 and 246:

The corresponding flux densities in

- Page 247 and 248:

The first term in equation (5.55) i

- Page 249 and 250:

The second term in (5.64) is zero u

- Page 251 and 252:

5.2.2 Torque Equation The calculati

- Page 253 and 254:

Re j( ω ) ⎧ 1t− P1θ µ 0r j(

- Page 255 and 256:

* ( ) ( ) ( ) ⎛ P1 ⋅ ⋅ ⎞ j

- Page 257 and 258:

* Since both ( ) C 2π ∫ 0 2 * Cs

- Page 259 and 260:

(A) Induced voltage in the ABC wind

- Page 261 and 262:

5.3.3 Equation of Torque Contribute

- Page 263 and 264:

winding set works as a generator, w

- Page 265 and 266:

possible for the brushless doubly-f

- Page 267 and 268:

Since the number of rotor bar is n,

- Page 269 and 270:

5.6 Computer Simulation and Experim

- Page 271 and 272:

Figure 5.2. Simulation results for

- Page 273 and 274:

5.7. Conclusions In this chapter, u

- Page 275 and 276:

good steady-state predictions and c

- Page 277 and 278:

which are superimposed some space h

- Page 279 and 280:

(a) (b) (c) Figure 6.1: Main flux s

- Page 281 and 282:

(a) (b) (c) (d) (e) Figure 6.3: Fin

- Page 283 and 284:

(a) (b) Figure 6.5: Induced air-gap

- Page 285 and 286:

Substituting (6.7) into (6.4-6.6),

- Page 287 and 288:

L L L L L L L λ + lr1 m1 ls1 m1 lr

- Page 289 and 290:

6.4 Simulation and Experimental Res

- Page 291 and 292:

Figure 6.7 . Simulation results for

- Page 293 and 294:

Figure 6.9 Experimental results for

- Page 295 and 296:

diminish the contribution of the 6-

- Page 297 and 298:

CHAPTER 7 STEADY STATE ANALYSIS OF

- Page 299 and 300:

where, L L = (7.11) si mi iqdri λq

- Page 301 and 302:

Overall efficiency of the dual stat

- Page 303 and 304:

Figure 7.2 Stator current speed cha

- Page 305 and 306:

Figure 7.6 Power factor speed chara

- Page 307 and 308:

Figure 7.9 Power factor speed chara

- Page 309 and 310:

7.3.5 f = 35Hz and f = 90 Hz abc xy

- Page 311 and 312:

Figure 7.16 Torque speed characteri

- Page 313 and 314:

this conclusion is based on the ass

- Page 315 and 316:

Figure 7.21. ω s1 vs s2 ω when to

- Page 317 and 318:

Figure 7.25 ω s1 vs s2 ω when the

- Page 319 and 320:

Figure 7.28. Copper losses of the m

- Page 321 and 322:

7.4 Conclusions Based on the steady

- Page 323 and 324:

applications and possible use as st

- Page 325 and 326:

L pλ + λ = I − = σ (8.3) ( ω

- Page 327 and 328:

espectively. The stator q and d axi

- Page 329 and 330:

* 3 * ( V I ) V Re( M I ) 3 P p = R

- Page 331 and 332:

the modulation index of the rectifi

- Page 333 and 334:

Lie derivative and relative order d

- Page 335 and 336:

The above algorithm requires that t

- Page 337 and 338:

σ = 3 1+ K ( Vqs1iqs1 + Vds1 ds1)

- Page 339 and 340:

Butterworth polynomial with the den

- Page 341 and 342:

Table 8.1 Parameters of controllers

- Page 343 and 344:

generally the case to get a good pe

- Page 345 and 346:

Table 8.2 Machine parameters for si

- Page 347 and 348:

(a) (b) (c) (d) (e) (f) (g) Figure

- Page 349 and 350:

(a) (b) (c) (d) (e) (f) (g) (h) (i)

- Page 351 and 352:

(a) (b) (c) (d) (e) (f) (g) (h) (i)

- Page 353 and 354:

CHAPTER 9 HIGH PERFORMANCE CONTROL

- Page 355 and 356:

The qd0 voltage equations of a dual

- Page 357 and 358:

317 ( ) ( ) ( ) ( ) ( ) ⎥ ⎥ ⎥

- Page 359 and 360:

If the rotor speed and the rotor fl

- Page 361 and 362:

Infeasible region (a) Vdc1 and Vdc2

- Page 363 and 364:

The influences of the saturation of

- Page 365 and 366:

Figure 9.5(a), by varying the q-axi

- Page 367 and 368:

Figure 9.5 Steady state analysis, (

- Page 369 and 370:

L1 L3 2 ( 1− K ) Vdc1 3 = ( Vqs1i

- Page 371 and 372:

If the PI controllers are used and

- Page 373 and 374:

egulation capabilities of the contr

- Page 375 and 376:

(a) (b) (c) (d) (e) (f) (g) (h) (k)

- Page 377 and 378:

(a) (b) Figure 9.11. The starting p

- Page 379 and 380:

9.6 Conclusions The high performanc

- Page 381 and 382:

induction machine are applicable to

- Page 383 and 384:

In section 10.2, the fundamentals o

- Page 385 and 386:

The vector control of an induction

- Page 387 and 388:

possibilities for fault conditions,

- Page 389 and 390:

where, where, − r r L = (10.18) (

- Page 391 and 392:

qsi qsi * ( I I ) σ = K ⋅ − (1

- Page 393 and 394:

In the proposed control scheme, rot

- Page 395 and 396:

* ωr * ωr + + − ωr k p + ki s

- Page 397 and 398:

The value of ω 0 determines the dy

- Page 399 and 400:

10.4.4 Stator D-axis Current Contro

- Page 401 and 402:

(a) (b) (c) (d) (e) (f) Figure 10.4

- Page 403 and 404:

The proposed control scheme has als

- Page 405 and 406:

(a) (b) (c) (d) (e) (f) (g) Figure

- Page 407 and 408:

10.6 Full-order Flux Observer The c

- Page 409 and 410:

while the second three-phase windin

- Page 411 and 412:

L r L p ˆ λ ˆ ˆ (10.66) ri si r

- Page 413 and 414:

373 [ ] ( ) ( ) ( ) ( ) ( ) ( ) ( )

- Page 415 and 416:

t 2bi ⎛ rsiLri K iL ⎞ ⎛ ri K

- Page 417 and 418:

ri D i si ri ri si mi ri 2 ( K )

- Page 419 and 420:

esults show that the selected obser

- Page 421 and 422:

Figure 10.12 The poles of the 6-pol

- Page 423 and 424:

383 ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( )

- Page 425 and 426: ⎧t s ⎨ ⎩ts 1 2 = t = t 1 2 Th

- Page 427 and 428: Figure 10.15 The poles of the machi

- Page 429 and 430: X i i = X Y = Y i i ( σ , ω) ( σ

- Page 431 and 432: this error is used as the feedback.

- Page 433 and 434: ˆ ω rm The output error is expres

- Page 435 and 436: The expressions of t1 i and t2 i ar

- Page 437 and 438: 397 ( ) ( ) ( ) bi ei i bi ei i ai

- Page 439 and 440: The transfer function of rotor spee

- Page 441 and 442: (a) (b) (c) (d) Figure 10.16 Pole-z

- Page 443 and 444: Figure 10.19 Pole-zero maps with di

- Page 445 and 446: Figure 10.22 Pole-zero maps with di

- Page 447 and 448: should ensure the stability under a

- Page 449 and 450: The boundary of the speed controlle

- Page 451 and 452: 10.11 Simulation Results for Sensor

- Page 453 and 454: Figure 10.28 Speed estimation for 2

- Page 455 and 456: (a) (b) Figure 10.31 Speed estimati

- Page 457 and 458: (a) (b) (c) (d) (e) (f) Figure 10.3

- Page 459 and 460: Figure 10.34 Actual and estimated v

- Page 461 and 462: CHAPTER 11 HARDWARE IMPLEMENTATION

- Page 463 and 464: esistance for two phase windings. T

- Page 465 and 466: 11.2.3 Short Circuit Test The short

- Page 467 and 468: When the input voltages of 2-pole A

- Page 469 and 470: winding set is generating and the o

- Page 471 and 472: 11.4 Per Unit Model For the fixed p

- Page 473 and 474: 1 = 12 2 0. 0024414 The transformat

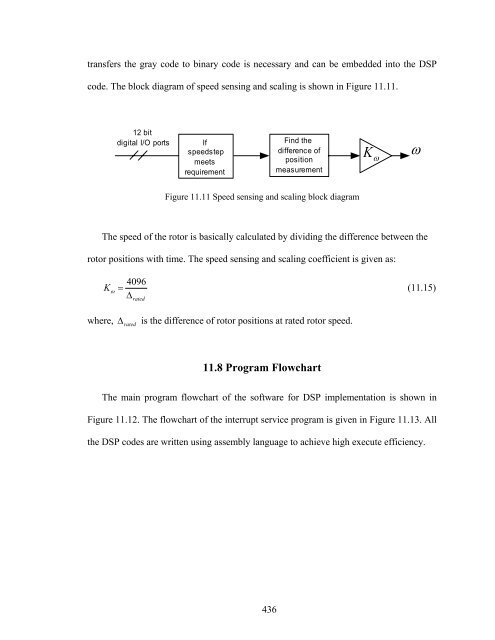

- Page 475: ase values of voltage/current. The

- Page 479 and 480: CHAPTER 12 CONCLUSIONS AND FUTURE W

- Page 481 and 482: Using the rotating-field theory and

- Page 483 and 484: each winding have been clearly show

- Page 485 and 486: voltages of different frequencies,

- Page 487 and 488: REFERENCES 447

- Page 489 and 490: [2.2]. P. C. Roberts, "A Study of B

- Page 491 and 492: [5.3]. R. A. McMahon, P. C. Roberts

- Page 493 and 494: [8.17]. O. Ojo, “Performance of s

- Page 495 and 496: [10.5]. J. C. Moreira, K. T. Hung,

- Page 497 and 498: [10.27]. M. Hinkkanen, “Analysis

- Page 499 and 500: [10.48]. K. Lee and F. Blaabjerg,

- Page 501 and 502: VITA Zhiqiao Wu was born in Shashi,

- Page 503: 3. Zhiqiao Wu and O. Ojo, "High Per