- Page 1 and 2: .••• ..J ~L'" ('1ty ";~';'t~l

- Page 3 and 4: ~~:., .. -,~~!. ~Jt:L' ·,BU' RESTR

- Page 5 and 6: i· .. ldil Subject Deck lug - - -

- Page 7 and 8: VI Maintenance and operating instru

- Page 9 and 10: Subject VIII Maintenance and operat

- Page 11 and 12: Maintenance and operating instructi

- Page 13 and 14: XII Subject Page Sight (cont'd.) Te

- Page 15 and 16: Subject Rammer XIV stroking control

- Page 17 and 18: PREFACE This edition of Ordnance Pa

- Page 19 and 20: 198 to point below a 24 inch diamet

- Page 21 and 22: 200 (b) Undervoltage protection.- A

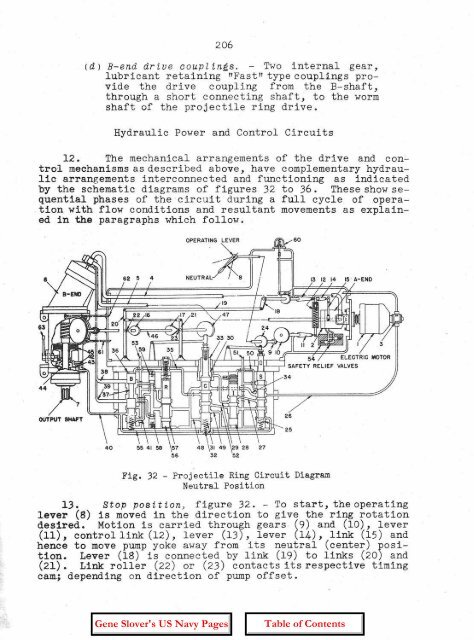

- Page 23 and 24: 202 response through gearing rotate

- Page 25: 204 The control link centering spri

- Page 29 and 30: 208 line (34) to line (35) then int

- Page 31 and 32: OUTPUT SHAFT 210 While doing so, ac

- Page 33 and 34: 212 (c ) start the electric motor.

- Page 35 and 36: CAM ROLLER CLEARANCE SHORT CAM LINK

- Page 37 and 38: 216 When this unit is properly asse

- Page 39 and 40: 218 Operating Trouble Diagnosis 35.

- Page 41 and 42: 220 38. Projectile ring inoperative

- Page 43 and 44: 222 yoke completely over. If operat

- Page 45 and 46: 224 (C) Hydraulic chatter or hammer

- Page 47 and 48: 226 180226-7 and lock washers 19673

- Page 49 and 50: , 228 Inasmuch as spring 271718-10

- Page 51 and 52: I - 230 Disc plates 271695-5 and 27

- Page 53 and 54: 232 THIS PAGE IS BLANK

- Page 55 and 56: 234 cylinder piston and attached ra

- Page 57 and 58: 236 Motor Data Type - - - - - 60 cy

- Page 59 and 60: 238 20. The fulcrwn and cradle asse

- Page 61 and 62: 240 ments of piston and cy.l i.nde

- Page 63 and 64: HOIST N~ LOWER SUPPLY TANK LEGEND M

- Page 65 and 66: 244 29. Tube pawl control mechanism

- Page 67 and 68: 246 32. The hydraulic arrangement o

- Page 69 and 70: 248 (C) Latch release. - The latch

- Page 71 and 72: .250 (f) Before operating the hoist

- Page 73 and 74: 252 50. Brake adjustment. - Refer d

- Page 75 and 76: 254 Fig. 50 - By-Pass Valve Adjustm

- Page 77 and 78:

256 without dis~urbing any of the h

- Page 79 and 80:

258 3. The components of each of th

- Page 81 and 82:

260 The Trunk Upper Door 11. The tr

- Page 83 and 84:

262 Powder Car 17. The powder car i

- Page 85 and 86:

264 ate and stop the car. when the

- Page 87 and 88:

STARTING LEVER SOLENOID "a" ---LJ.J

- Page 89 and 90:

268 the dog locking latch (upper do

- Page 91 and 92:

270 celera tion, in this method of

- Page 93 and 94:

272 39. Control l er . - The contro

- Page 95 and 96:

274 18 by 24 inch hatch. The disman

- Page 97 and 98:

276 to the linkage which controls t

- Page 99 and 100:

278 adjustable control rods. Needle

- Page 101 and 102:

280 position. This opens switch 6 a

- Page 103 and 104:

282 striction. The limits of adjust

- Page 105 and 106:

284 circui t is vented. The venting

- Page 107 and 108:

286 to the "E'Lec t.r-Lc aL" contro

- Page 109 and 110:

288 ual control. Observe the accura

- Page 111 and 112:

290 (a) With the control selector l

- Page 113 and 114:

292 (5) Nowadjust the length of the

- Page 115 and 116:

294 be lowered at a rate of six inc

- Page 117 and 118:

296 HOisting acceleration c am, -Ma

- Page 119 and 120:

CAM CLAMP SCREWS LOWERING DECELERAT

- Page 121 and 122:

LOWERING ACCELERATION CAM HOISTING

- Page 123 and 124:

302 Removethe two screws 196825-7,

- Page 125 and 126:

304 and the control rods between th

- Page 127 and 128:

306 see whether the faces of the br

- Page 129 and 130:

308 (1) The control pump relief val

- Page 131 and 132:

310 (8) Excessive leakage in the sy

- Page 133 and 134:

312 as whenusing "Ser'vo Electrical

- Page 135 and 136:

314 vibration for equipments of thi

- Page 137 and 138:

316 opposi te. It is good practice

- Page 139 and 140:

318 of assembly and to rm m.mi z e

- Page 141 and 142:

320 the end of the short lever 2742

- Page 143 and 144:

322 125. To reassemble the valve bl

- Page 145 and 146:

324 inspection purposes. The oil is

- Page 147 and 148:

326 143. To reassemble the brake ba

- Page 149 and 150:

328 154. To remove the oil seal (dr

- Page 151 and 152:

330 cylinder bearing pin 274319-1 t

- Page 153 and 154:

332 is to be sprung far enough to p

- Page 155 and 156:

334 274349-4 over the end of the ro

- Page 157 and 158:

I 336 (r) Thereafter proceed as fol

- Page 159 and 160:

I 338 (0) Before assembling the cam

- Page 161 and 162:

340 181. Safety car stop device cyl

- Page 163 and 164:

342 2. Thus t.ur-r-e t sights are p

- Page 165 and 166:

344 gun layer's and turret train op

- Page 167 and 168:

346 bevel gears are shaft connected

- Page 169 and 170:

348 holder except that there is pro

- Page 171 and 172:

350 37. The sight angle bevel gear

- Page 173 and 174:

352 90 0 adjustable head prism, a c

- Page 175 and 176:

354 train, to indicate that the tur

- Page 177 and 178:

356 all combinations where both sid

- Page 179 and 180:

358 adjustable coupling irnrnediate

- Page 181 and 182:

, i I ! 360 scri bed on the s truc

- Page 183 and 184:

362 shutter operating mechanism in

- Page 185 and 186:

364 INSTALLATION 2. A new hydraulic

- Page 187 and 188:

366 The tinning of male threads of

- Page 189 and 190:

368 if necessary. Furthermore whene

- Page 191 and 192:

370 acteristics shall not be made.

- Page 193 and 194:

372 THIS PAGE IS BLANK

- Page 195 and 196:

374 Appendix I (cont'd) 16-inch Tur

- Page 197 and 198:

376 Appendix I (cont'd) 16-inch Tur

- Page 199 and 200:

378 Appendix I (cont1d) 16-inch Tur

- Page 201 and 202:

380 Appendix I (conttd) 16-inch Tur

- Page 203 and 204:

382 AppendlX I (cont'd) 16-inch Tur

- Page 205 and 206:

384 Appendix I (cont'd.) l6-inch Tu

- Page 207 and 208:

386 Appendix I (contld.) 16-inch Tu

- Page 209 and 210:

388 Appendix I (contI d.) 16-inch T

- Page 211 and 212:

390 Appendix I (cont'd.) l6-inch Tu

- Page 213 and 214:

Chapter VIII references. 392 Symbol

- Page 215 and 216:

394 THIS PAGE IS BLANK

- Page 217 and 218:

396 (h) Adjust micrometer couplings

- Page 219 and 220:

398 of sight should cut the target

- Page 221 and 222:

Qhapter IX (contrd.). Control gear