OP-755 Part 2 Pages 197-401 - Personal Page of GENE SLOVER

OP-755 Part 2 Pages 197-401 - Personal Page of GENE SLOVER

OP-755 Part 2 Pages 197-401 - Personal Page of GENE SLOVER

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

236<br />

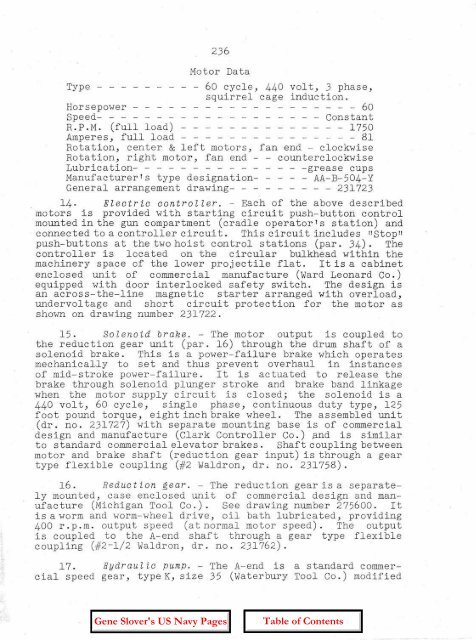

Motor Data<br />

Type - - - - - 60 cycle, 440 volt, 3 phase,<br />

squirrel cage induction.<br />

Horsepower - - - - - - - - - - - - - - - - - - - 60<br />

Speed- - - - - - - - - - - Constant<br />

R.P.M. (full load) - - - - - - - - - - - - - - 1750<br />

Amperes, full load - -- - - - - - - - 81<br />

Rotation, center & left motors, fan end - clockwise<br />

Rotation, right motor, fan end - - counterclockwise<br />

Lubrication- - - - - - - - - - - - - - -grease cups<br />

Manufacturer's type designation- - - AA-B-504-Y<br />

General arrangement drawing- - - - - - - - - 231723<br />

14. Electric controller. - Each <strong>of</strong> the above described<br />

motors is provided with starting circuit push-button control<br />

mounted in the gun compartment (cradle operator's station) and<br />

connected to a controller circui t. This circui t includes IIStopll<br />

push-buttons at the two hoist control stations (par. 34). The<br />

controller is located on the circular bulkhead within the<br />

machinery space <strong>of</strong> the lower proj ectile flat. It is a cabinet<br />

enclosed unit <strong>of</strong> commercial manufacture (Ward Leonard Co.)<br />

equipped with door interlocked safety switch. The design is<br />

an across-the-line magnetic starter arranged with overload,<br />

undervol tage and short circuit protec tion for the motor as<br />

shown on drawing number 231722.<br />

15. Solenoid brake. - The motor output is coupled to<br />

the reduction gear unit (par. 16) through the drum shaft <strong>of</strong> a<br />

solenoid brake. This is a power-failure brake which operates<br />

mechani caLl.y to set and thus prevent overhaul in instances<br />

<strong>of</strong> mid-stroke power-failure. It is actuated to release the<br />

brake through solenoid plunger stroke and brake band linkage<br />

when the motor supply circuit is closed; the solenoid is a<br />

440 volt, 60 cycle, single phase, continuous duty type, 125<br />

foot pound torque, eight inch brake wheel. The assembled unit<br />

(dr. no. 231727) with separate mounting base is <strong>of</strong> commercial<br />

design and manufacture (Clark Controller Co.) and is similar<br />

to standard commercial elevator brakes. Shaft coupling between<br />

motor and brake shaft (reduction gear input) is through a gear<br />

type flexible coupling (#2 Waldron, dr; no. 231758).<br />

16. Retiuc t ion gear. - The reduction gear is a separately<br />

mounted, case enclosed uni t <strong>of</strong> commercial design and manufacture<br />

(Michigan Tool Co.). See drawing number 275600. It<br />

is a worm and worm-wheel drive, oil bath lubricated, providing<br />

400 r.p.m. output speed (at normal motor speed). The output<br />

is coupled to the A-end shaft through a gear type flexible<br />

coupling (#2-1/2 Waldron, dr. no. 231762).<br />

17. Hydrau l i c pump. - The A-end is a standard commercial<br />

speed gear, type K, size 35 (Waterbury Tool Co.) modified