OP-755 Part 2 Pages 197-401 - Personal Page of GENE SLOVER

OP-755 Part 2 Pages 197-401 - Personal Page of GENE SLOVER

OP-755 Part 2 Pages 197-401 - Personal Page of GENE SLOVER

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

235<br />

head ports and the design <strong>of</strong> the<br />

piston assembly operate to provide<br />

dashpot buffing at both extremes<br />

<strong>of</strong> piston stroke. The upper<br />

head buffing space is equipped<br />

with needle type vent valve.<br />

10. The piston and rod assembly<br />

is a single cupped-leather<br />

type whi ch operates to seal by<br />

pressure distension. It consists<br />

<strong>of</strong> a steel rod (2.5 in. dia.) and<br />

a bronze piston, Hith the leather<br />

secured by bolted attdclnuent thru<br />

a piston folloHer. This follower<br />

is shaped to prevent collapse <strong>of</strong><br />

the leather and to function as the<br />

dOHn stroke buffer plunger.<br />

The upper end <strong>of</strong> the rod is secured<br />

to the crosshead Hith a steel pin<br />

(1. 5 in. dia.) 'lockedin place Hi th<br />

1/2 inch set screw.<br />

11. The cylinder head pressure<br />

ports are flange coupled to<br />

special steel leads (2.375 ins.<br />

dia.) which extend upward Hi th<br />

!ieasyllbends to attachment Hith<br />

the A-end valve plate on the electric<br />

deck.<br />

Power Drive Assembly<br />

12. The power drives for<br />

all hoists are located on the electric<br />

deck with arrangement as<br />

shown on drawing number 215940.<br />

Each power plant consists <strong>of</strong> an<br />

electric motor with controller<br />

panel and remote push-button station,<br />

a reduction gear, a variable<br />

displacement pump and a solenoid<br />

brake.<br />

13. El ec t r i c motor. - The<br />

electric motor is an induction type<br />

<strong>of</strong> ccmmercLaL manufacture (RelianceElec.<br />

&Eng. Co.) mounted vi.t.h<br />

rotor axis horizontal and having<br />

the following specification data.<br />

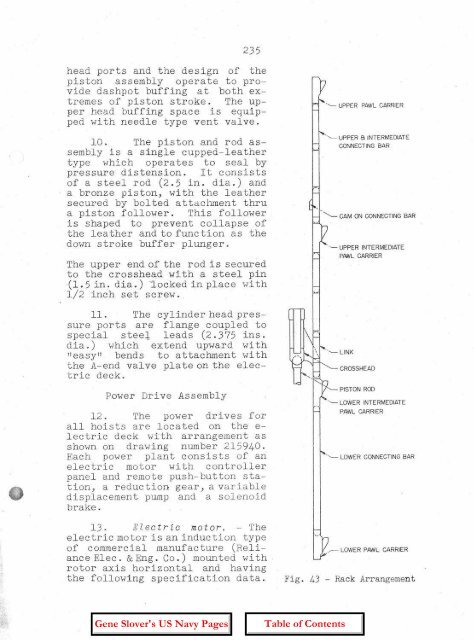

" ',- UPPER PAWL CARRIER<br />

'~ UPPER B INTERMEDIATE<br />

CONNECTING BAR<br />

"------ CAM ON CONNECTING BAR<br />

'~UPPER INTERMEDIATE<br />

PAWL CARRIER<br />

CROSSHEAD<br />

PISTON ROD<br />

'~LOWER INTERMEDIATE<br />

PAWL CARRIER<br />

'- LOWER CONNECTING BAR<br />

.r=:; LOWER PAWL CARRIER<br />

Fig. 43 - Rack Arrangement