- Page 2 and 3:

1 Introduction 1.1 THE ELECTRICAL/E

- Page 4 and 5:

� S I mind that similar progressi

- Page 6 and 7:

� S I denser, which we refer to t

- Page 8 and 9:

� S I decades will probably conta

- Page 10 and 11:

� S I TABLE 1.1 Comparison of the

- Page 12 and 13:

� S I The second was originally d

- Page 14 and 15:

� S I A quick method of determini

- Page 16 and 17:

� S I revealing that the operatio

- Page 18 and 19:

� S I 1 1 2300 � � 3.333E�1

- Page 20 and 21:

� S I Since the power of ten will

- Page 22 and 23:

� S I EXAMPLE 1.14 a. Determine t

- Page 24 and 25:

� S I Initial Settings Format and

- Page 26 and 27:

� S I c. Since the division will

- Page 28 and 29:

� S I Three software packages wil

- Page 30 and 31:

� S I SECTION 1.8 Conversion with

- Page 32 and 33:

2 Current and Voltage 2.1 ATOMS AND

- Page 34 and 35:

I e V CURRENT ⏐⏐⏐ 33 the dist

- Page 36 and 37:

I e V The chemical activity of the

- Page 38 and 39:

I e V erence plane. If the weight i

- Page 40 and 41:

I e V 2.4 FIXED (dc) SUPPLIES The t

- Page 42 and 43:

I e V FIG. 2.14 Maintenance-free 12

- Page 44 and 45:

I e V batteries are relatively warm

- Page 46 and 47:

I e V EXAMPLE 2.5 a. Determine the

- Page 48 and 49:

I e V TABLE 2.1 Relative conductivi

- Page 50 and 51:

I e V be accomplished is to open th

- Page 52 and 53:

I e V (a) (c) Contact Sliding switc

- Page 54 and 55:

I e V Control switch Meter leads (a

- Page 56 and 57:

I e V tant to disconnect the charge

- Page 58 and 59:

I e V GLOSSARY ⏐⏐⏐ 57 28. Fin

- Page 60 and 61:

3 Resistance 3.1 INTRODUCTION The f

- Page 62 and 63:

R G Note that the area of the condu

- Page 64 and 65:

R G EXAMPLE 3.3 What is the resista

- Page 66 and 67:

R G RESISTANCE: METRIC UNITS ⏐⏐

- Page 68 and 69:

R G The conversion factor between r

- Page 70 and 71:

R G Absolute zero -273.15°C Inferr

- Page 72 and 73:

R G Since R 20 of Eq. (3.8) is the

- Page 74 and 75:

R G result is a tremendous saving i

- Page 76 and 77:

R G TYPES OF RESISTORS ⏐⏐⏐ 75

- Page 78 and 79:

R G TYPES OF RESISTORS ⏐⏐⏐ 77

- Page 80 and 81:

R G a 1% failure rate would reveal

- Page 82 and 83:

R G gaps. Dropping to the 10% level

- Page 84 and 85:

R G THERMISTORS ⏐⏐⏐ 83 Prelim

- Page 86 and 87:

R G APPLICATIONS ⏐⏐⏐ 85 3.14

- Page 88 and 89:

R G longer heating element in stand

- Page 90 and 91:

R G cally this law relates voltage,

- Page 92 and 93:

R G MATHCAD ⏐⏐⏐ 91 key at the

- Page 94 and 95:

R G *13. What is the new resistance

- Page 96:

R G SECTION 3.13 Varistors 58. a. R

- Page 99 and 100:

98 ⏐⏐⏐ OHM’S LAW, POWER, AN

- Page 101 and 102:

100 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 103 and 104:

102 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 105 and 106:

104 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 107 and 108:

106 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 109 and 110:

108 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 111 and 112:

110 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 113 and 114:

112 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 115 and 116:

114 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 117 and 118:

116 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 119 and 120:

118 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 121 and 122:

120 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 123 and 124:

122 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 125 and 126:

124 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 127 and 128:

126 ⏐⏐⏐ OHM’S LAW, POWER, A

- Page 130 and 131:

5 Series Circuits 5.1 INTRODUCTION

- Page 132 and 133:

S the same through series elements

- Page 134 and 135:

S Solution: RT � R1 � R2 � R3

- Page 136 and 137:

S type of element. In other words,

- Page 138 and 139:

S c. V1 � IR1 � (2 A)(4 �)

- Page 140 and 141:

S In the above discussion the curre

- Page 142 and 143:

S Voltage Sources and Ground Except

- Page 144 and 145:

S EXAMPLE 5.14 Find the voltage Vab

- Page 146 and 147:

S EXAMPLE 5.19 Using the voltage di

- Page 148 and 149:

S ∆V L 120 V 100 V 0 V L voltage

- Page 150 and 151:

S EXAMPLE 5.24 Determine the voltag

- Page 152 and 153:

S 5.11 APPLICATIONS Holiday Lights

- Page 154 and 155:

S wiring, you will find that since

- Page 156 and 157:

S and right-click on the mouse. A l

- Page 158 and 159:

S FIG. 5.68 Applying Electronics Wo

- Page 160 and 161:

S also be used to remind the progra

- Page 162 and 163:

S 3. Find the applied voltage E nec

- Page 164 and 165:

S 9. Determine the current I and th

- Page 166 and 167:

S 40 V I + R 3 R 2 R 1 V 3 - 30 �

- Page 168 and 169:

S *28. For the network of Fig. 5.97

- Page 170 and 171:

6 Parallel Circuits 6.1 INTRODUCTIO

- Page 172 and 173:

P rent level. In other words, as th

- Page 174 and 175:

P EXAMPLE 6.4 a. Find the total res

- Page 176 and 177:

P R T R 6 � R′ T � �� �

- Page 178 and 179:

P d. RT � 30 � � 30 � � 0

- Page 180 and 181:

P 0.25 S � 0.1 S � 0.05 S � 0

- Page 182 and 183:

P EXAMPLE 6.13 Determine the curren

- Page 184 and 185:

P I2 � I4 � I5 12 A � I4 �

- Page 186 and 187:

P For the particular case of two pa

- Page 188 and 189:

P and (R 1 � R 2)I 1 � R 2I R 1

- Page 190 and 191:

P A short circuit is a very low res

- Page 192 and 193:

P must therefore be zero volts, as

- Page 194 and 195:

P + E - A + - I s + - ensure a posi

- Page 196 and 197:

P 12-gage fuse link Filter capacito

- Page 198 and 199:

P car such as the lights, air condi

- Page 200 and 201:

P careful, you can work with one li

- Page 202 and 203:

P In particular, note that m (or M)

- Page 204 and 205:

P This time, rather than using mete

- Page 206 and 207:

P PROBLEMS ⏐⏐⏐ 205 *6. Determ

- Page 208 and 209:

P 14. Using the information provide

- Page 210 and 211:

P *21. Find the unknown quantities

- Page 212 and 213:

P SECTION 6.8 Open and Short Circui

- Page 214 and 215:

7 Series-Parallel Networks 7.1 SERI

- Page 216 and 217:

S S P P For parallel resistors R 1

- Page 218 and 219:

S S P P a I A E 16.8 V R 1 9 � R

- Page 220 and 221:

S S P P I s R T E 24 V R 6 � R1

- Page 222 and 223:

S S P P R 3 R 2 7 � 5 � I 3 R 4

- Page 224 and 225:

S S P P E 72 V 72 V I5 ���

- Page 226 and 227:

S S P P (6 �)I3 6 I6 ���

- Page 228 and 229:

S S P P To demonstrate the validity

- Page 230 and 231:

S S P P 7.5 POTENTIOMETER LOADING F

- Page 232 and 233:

S S P P The Ammeter The maximum cur

- Page 234 and 235:

S S P P ammeter or voltmeter becaus

- Page 236 and 237:

S S P P 120 V + - VR1 R1 + - 1 �

- Page 238 and 239:

S S P P would be created between th

- Page 240 and 241:

S S P P Note also that the current

- Page 242 and 243:

S S P P 7.9 COMPUTER ANALYSIS PSpic

- Page 244 and 245:

Heading Preprocessor directive Defi

- Page 246 and 247:

S S P P 3. For the network of Fig.

- Page 248 and 249:

S S P P 10. For the network of Fig.

- Page 250 and 251:

S S P P 17. For the configuration o

- Page 252 and 253:

S S P P 26. For the ladder network

- Page 254 and 255:

S S P P 34. Using a 50-mA, 1000-�

- Page 256 and 257:

8 Methods of Analysis and Selected

- Page 258 and 259:

N A current-source networks, it wil

- Page 260 and 261:

N A excellent approximation to drop

- Page 262 and 263:

N A EXAMPLE 8.7 Reduce the network

- Page 264 and 265:

N A of series elements. Figure 8.20

- Page 266 and 267:

N A appearing in Solution 1 in a ve

- Page 268 and 269:

N A R 1 E 1 - + + - 4 � 15 V Appl

- Page 270 and 271:

N A EXAMPLE 8.11 Consider the same

- Page 272 and 273:

N A EXAMPLE 8.13 Find the branch cu

- Page 274 and 275:

N A Node a is then used to relate t

- Page 276 and 277:

N A 1. Assign a loop current to eac

- Page 278 and 279:

N A EXAMPLE 8.18 Find the current t

- Page 280 and 281:

N A The nodal analysis method is ap

- Page 282 and 283:

N A or I � � � and V2� �

- Page 284 and 285:

N A Step 3: Included in Fig. 8.49 f

- Page 286 and 287:

N A I 3 V 1 I 1 R 3 10 � 6 A R1 4

- Page 288 and 289:

N A EXAMPLE 8.23 Write the nodal eq

- Page 290 and 291:

N A EXAMPLE 8.25 Using nodal analys

- Page 292 and 293:

N A Solution: The nodal voltages ar

- Page 294 and 295:

N A with the bottom of the determin

- Page 296 and 297:

N A any unknown quantities if mesh

- Page 298 and 299:

N A To obtain the relationships nec

- Page 300 and 301:

N A Solution: RB RC (20 �)(10 �

- Page 302 and 303:

N A 8.13 APPLICATIONS The Applicati

- Page 304 and 305:

N A or outside forces such as light

- Page 306 and 307:

N A Schematic with Nodal Voltages W

- Page 308 and 309:

N A A photograph of the outside and

- Page 310 and 311:

N A PROBLEMS SECTION 8.2 Current So

- Page 312 and 313:

N A SECTION 8.4 Current Sources in

- Page 314 and 315:

N A *16. For the transistor configu

- Page 316 and 317:

N A SECTION 8.8 Mesh Analysis (Form

- Page 318 and 319:

N A *37. Using the supernode approa

- Page 320 and 321:

N A *49. Repeat Problem 48 for the

- Page 322 and 323:

9 Network Theorems 9.1 INTRODUCTION

- Page 324 and 325:

Th This final relationship between

- Page 326 and 327:

Th The total current through the 4-

- Page 328 and 329:

I Th R 1 6 mA R 3 Current divider r

- Page 330 and 331:

Th E 1 12 V 6 � 4 V E 2 4 � (a)

- Page 332 and 333:

Th R 1 3 � R 2 6 � a R Th b b (

- Page 334 and 335: Th R 1 R 1 6 � 6 � R 4 a 3 �

- Page 336 and 337: Th 6 � R 1 R 2 12 � b R3 a R4 3

- Page 338 and 339: Th Direct Measurement of E Th and R

- Page 340 and 341: Th Conclusion: 5. Draw the Norton e

- Page 342 and 343: Th NORTON’S THEOREM ⏐⏐⏐ 341

- Page 344 and 345: Th E Th I N R N FIG. 9.78 Defining

- Page 346 and 347: Th Note, in particular, that P L is

- Page 348 and 349: Th When R L � R Th, R L h% ��

- Page 350 and 351: Th EXAMPLE 9.14 A dc generator, bat

- Page 352 and 353: Th Note Fig. 9.91, where V1 � V3

- Page 354 and 355: Th that of E 1 and E 3. The total c

- Page 356 and 357: Th combination of elements that wil

- Page 358 and 359: Th RT � R1 � R2 � (R3 � R4)

- Page 360 and 361: Th are presented with a bundle of r

- Page 362 and 363: Th FIG. 9.116 Using PSpice to deter

- Page 364 and 365: Th FIG. 9.119 Using PSpice to deter

- Page 366 and 367: Th FIG. 9.121 Plot resulting from t

- Page 368 and 369: Th 2. Using superposition, find the

- Page 370 and 371: Th *8.Find the Thévenin equivalent

- Page 372 and 373: Th 21. For each network of Fig. 9.1

- Page 374 and 375: Th SECTION 9.8 Reciprocity Theorem

- Page 376 and 377: 10 Capacitors 10.1 INTRODUCTION Thu

- Page 378 and 379: The attraction and repulsion betwee

- Page 380 and 381: w � Q, so the dielectric is also

- Page 382 and 383: d � o d d C = 5 µF A (a) C = 0.1

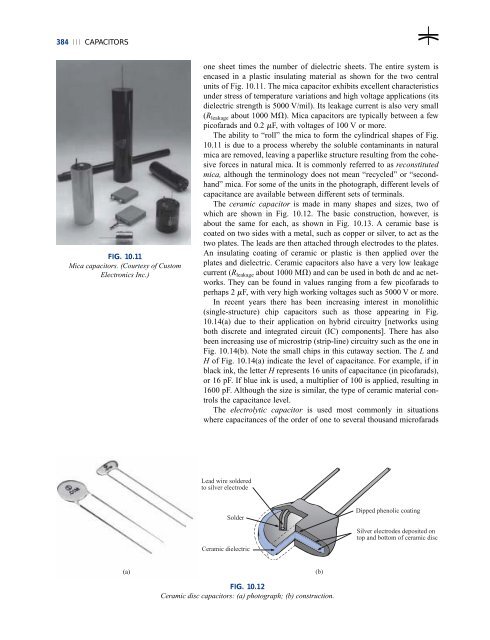

- Page 386 and 387: Dipped phenolic coating Ceramic die

- Page 388 and 389: lower potential. This capacitor can

- Page 390 and 391: Type: Miniature Axial Electrolytic

- Page 392 and 393: The factor e �t/RC is an exponent

- Page 394 and 395: after five time constants of the ch

- Page 396 and 397: which employs the function e �x a

- Page 398 and 399: Solutions: a. Charging phase: vC

- Page 400 and 401: t2 � (R2 � R3)C � (1 k��3

- Page 402 and 403: a. Find the mathematical expression

- Page 404 and 405: and C t ��t loge�1 � �v

- Page 406 and 407: 10.11 THÉVENIN EQUIVALENT: t � R

- Page 408 and 409: Solution: The network is redrawn in

- Page 410 and 411: �v 4 v 3 v2 0 v C (V) 1 t2 t3 �

- Page 412 and 413: and substituting for C T: 1/C 1 V 1

- Page 414 and 415: Solution: As previously discussed,

- Page 416 and 417: Flash Lamp The basic circuitry for

- Page 418 and 419: light in parallel with the capacito

- Page 420 and 421: Black (feed) Ground Black White Gro

- Page 422 and 423: sufficiently large to be considered

- Page 424 and 425: FIG. 10.77 Using PSpice to investig

- Page 426 and 427: Settings-AverageIC dialog box. Anal

- Page 428 and 429: 16. Find the distance in millimeter

- Page 430 and 431: 29. For the situation of Problem 25

- Page 432 and 433: *40. The capacitor of Fig. 10.100 i

- Page 434 and 435:

*47. For the network of Fig. 10.107

- Page 436 and 437:

11 Magnetic Circuits 11.1 INTRODUCT

- Page 438 and 439:

Magnetic flux lines I Conductor FIG

- Page 440 and 441:

EXAMPLE 11.1 For the core of Fig. 1

- Page 442 and 443:

Substituting, we have (11.4) The ma

- Page 444 and 445:

- H s - B max e Saturation B R d -

- Page 446 and 447:

1.4 1.3 1.2 1.1 1.0 0.9 0.8 0.7 0.6

- Page 448 and 449:

above is evidenced by the fact that

- Page 450 and 451:

An approach frequently employed in

- Page 452 and 453:

and the magnetizing force is H (she

- Page 454 and 455:

The flux density of the air gap in

- Page 456 and 457:

� � 0 Hbelbe � Hbcdelbcde �

- Page 458 and 459:

EXAMPLE 11.9 Find the magnetic flux

- Page 460 and 461:

Speakers and Microphones Electromag

- Page 462 and 463:

4,000,000,000,000 bits of informati

- Page 464 and 465:

ingly enough one that perhaps will

- Page 466 and 467:

Hall Effect Sensor The Hall effect

- Page 468 and 469:

ciently close to establish contact

- Page 470 and 471:

SECTION 11.8 Hysteresis 9. For the

- Page 472 and 473:

*18. For the series-parallel magnet

- Page 474 and 475:

12 Inductors 12.1 INTRODUCTION We h

- Page 476 and 477:

Inductors are coils of various dime

- Page 478 and 479:

(a) (d) (b) FIG. 12.10 Various type

- Page 480 and 481:

ciated with the applied ac signal m

- Page 482 and 483:

the voltage across the coil is not

- Page 484 and 485:

y 1.0 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0

- Page 486 and 487:

12.8 INITIAL VALUES This section wi

- Page 488 and 489:

Let us now test the validity of the

- Page 490 and 491:

The mathematical expression for the

- Page 492 and 493:

v R1 R1 Defined polarity + vL - v L

- Page 494 and 495:

iL � (1 � e �t/t ) t � �

- Page 496 and 497:

12.12 INDUCTORS IN SERIES AND PARAL

- Page 498 and 499:

Applying the current divider rule,

- Page 500 and 501:

EXAMPLE 12.12 Find the energy store

- Page 502 and 503:

+ Feed 120 V ac - Return ���

- Page 504 and 505:

would need for 15 W, not to mention

- Page 506 and 507:

will scatter to all sides of the mo

- Page 508 and 509:

ing trace appears in the bottom of

- Page 510 and 511:

FIG. 12.61 Using PSpice to determin

- Page 512 and 513:

Parameters, use 0 s as the Start ti

- Page 514 and 515:

*11. Find the waveform for the curr

- Page 516 and 517:

*19. For the network of Fig. 12.76:

- Page 518 and 519:

*29. The switch of Fig. 12.83 has b

- Page 520:

37. Find the voltage V 1 and the cu

- Page 523 and 524:

522 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 525 and 526:

524 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 527 and 528:

526 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 529 and 530:

528 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 531 and 532:

530 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 533 and 534:

532 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 535 and 536:

534 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 537 and 538:

536 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 539 and 540:

538 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 541 and 542:

540 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 543 and 544:

542 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 545 and 546:

544 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 547 and 548:

546 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 549 and 550:

548 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 551 and 552:

550 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 553 and 554:

552 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 555 and 556:

554 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 557 and 558:

556 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 559 and 560:

558 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 561 and 562:

560 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 563 and 564:

562 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 565 and 566:

564 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 567 and 568:

566 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 569 and 570:

568 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 571 and 572:

570 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 573 and 574:

572 ⏐⏐⏐ SINUSOIDAL ALTERNATIN

- Page 576 and 577:

14 The Basic Elements and Phasors 1

- Page 578 and 579:

� RESPONSE OF BASIC R, L, AND C E

- Page 580 and 581:

� The opposition established by a

- Page 582 and 583:

� Therefore, RESPONSE OF BASIC R,

- Page 584 and 585:

� RESPONSE OF BASIC R, L, AND C E

- Page 586 and 587:

� RESPONSE OF BASIC R, L, AND C E

- Page 588 and 589:

� RESPONSE OF BASIC R, L, AND C E

- Page 590 and 591:

� is directly related to the stra

- Page 592 and 593:

� applied. In general, therefore,

- Page 594 and 595:

� θv the voltage or current. The

- Page 596 and 597:

� EXAMPLE 14.11 Determine the ave

- Page 598 and 599:

� any number not on the real axis

- Page 600 and 601:

� Polar to Rectangular X � Z co

- Page 602 and 603:

� Reciprocal The reciprocal of a

- Page 604 and 605:

� - Multiplication To multiply tw

- Page 606 and 607:

� Solutions: a. By Eq. (14.34), b

- Page 608 and 609:

� often frustrating if one lost m

- Page 610 and 611:

� CALCULATOR AND COMPUTER METHODS

- Page 612 and 613:

� PHASORS ⏐⏐⏐ 611 is entere

- Page 614 and 615:

� PHASORS ⏐⏐⏐ 613 6 A v 1 =

- Page 616 and 617:

� PHASORS ⏐⏐⏐ 615 - 2 p 41.

- Page 618 and 619:

� COMPUTER ANALYSIS ⏐⏐⏐ 617

- Page 620 and 621:

� COMPUTER ANALYSIS ⏐⏐⏐ 619

- Page 622 and 623:

� COMPUTER ANALYSIS ⏐⏐⏐ 621

- Page 624 and 625:

� COMPUTER ANALYSIS ⏐⏐⏐ 623

- Page 626 and 627:

� PROBLEMS ⏐⏐⏐ 625 *20. For

- Page 628 and 629:

� PROBLEMS ⏐⏐⏐ 627 *47. a.

- Page 630 and 631:

15 Series and Parallel ac Circuits

- Page 632 and 633:

a c v � 100 sin qt ⇒ phasor for

- Page 634 and 635:

a c v � 24 sin qt ⇒ phasor form

- Page 636 and 637:

a c v � 15 sin qt ⇒ phasor nota

- Page 638 and 639:

a c real and imaginary axes and fin

- Page 640 and 641:

a c In rectangular form, and VR �

- Page 642 and 643:

a c Time domain: In the time domain

- Page 644 and 645:

a c or E � V R � V L � V C wh

- Page 646 and 647:

a c (6�0)*(50�30)/((6�0)�(9

- Page 648 and 649:

a c Therefore, E � �(1�3�.3

- Page 650 and 651:

a c f � 1 kHz XC � � �15.92

- Page 652 and 653:

a c f � 0 Hz XC � � ⇒ very

- Page 654 and 655:

a c ohms and the short-circuit equi

- Page 656 and 657:

a c elements by 90°, and leads the

- Page 658 and 659:

a c EXAMPLE 15.12 For the network o

- Page 660 and 661:

a c EXAMPLE 15.14 Find the admittan

- Page 662 and 663:

a c I Admittance diagram: As shown

- Page 664 and 665:

a c E Admittance diagram: As shown

- Page 666 and 667:

a c Phasor notation: As shown in Fi

- Page 668 and 669:

a c Using Eq. (15.32), we obtain G

- Page 670 and 671:

a c on the total impedance at that

- Page 672 and 673:

a c 90° 60° 45° 30° 0° θ T In

- Page 674 and 675:

a c 0° -30° -45° -60° -90° θL

- Page 676 and 677:

a c The total impedance at the freq

- Page 678 and 679:

a c Solution: Rp � 8k� Xp (resu

- Page 680 and 681:

a c I = 12 A ∠ 0° FIG. 15.95 Ser

- Page 682 and 683:

a c + e - a + v R - R impedance. Th

- Page 684 and 685:

a c Switched outlets Parallel outle

- Page 686 and 687:

a c transfer of power (see Section

- Page 688 and 689:

a c Consequently, the sound generat

- Page 690 and 691:

a c V applied 170 80.24 V(volts) V

- Page 692 and 693:

a c Run PSpice key. The result will

- Page 694 and 695:

a c Electronics Workbench We will n

- Page 696 and 697:

a c PROBLEMS SECTION 15.2 Impedance

- Page 698 and 699:

a c 7. For the circuit of Fig. 15.1

- Page 700 and 701:

a c + E = 20 V ∠ 70° - 20 � (a

- Page 702 and 703:

a c SECTION 15.7 Admittance and Sus

- Page 704 and 705:

a c 31. Repeat Problem 30 for the c

- Page 706 and 707:

a c 41. For the network of Fig. 15.

- Page 708:

a c GLOSSARY Admittance A measure o

- Page 711 and 712:

710 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 713 and 714:

712 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 715 and 716:

714 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 717 and 718:

716 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 719 and 720:

718 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 721 and 722:

720 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 723 and 724:

722 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 725 and 726:

724 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 727 and 728:

726 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 729 and 730:

728 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 731 and 732:

730 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 733 and 734:

732 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 735 and 736:

734 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 737 and 738:

736 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 739 and 740:

738 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 741 and 742:

740 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 743 and 744:

742 ⏐⏐⏐ SERIES-PARALLEL ac NE

- Page 745 and 746:

744 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 747 and 748:

746 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 749 and 750:

748 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 751 and 752:

750 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 753 and 754:

752 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 755 and 756:

754 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 757 and 758:

756 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 759 and 760:

758 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 761 and 762:

760 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 763 and 764:

762 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 765 and 766:

764 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 767 and 768:

766 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 769 and 770:

768 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 771 and 772:

770 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 773 and 774:

772 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 775 and 776:

774 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 777 and 778:

776 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 779 and 780:

778 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 781 and 782:

780 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 783 and 784:

782 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 785 and 786:

784 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 787 and 788:

786 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 789 and 790:

788 ⏐⏐⏐ METHODS OF ANALYSIS A

- Page 792 and 793:

18 Network Theorems (ac) 18.1 INTRO

- Page 794 and 795:

Th Z 1 E 1- + Z 1 I s1 j 4 � Z1

- Page 796 and 797:

Th EXAMPLE 18.4 For the network of

- Page 798 and 799:

Th pendent sources. The solution ob

- Page 800 and 801:

Th is the replacement of the term r

- Page 802 and 803:

Th Z1 � R1 � j XL1 � 6 ��

- Page 804 and 805:

Th will behave like the actual tran

- Page 806 and 807:

Th obtained by applying a source of

- Page 808 and 809:

Th Method 3: See Fig. 18.49. Eg Ig

- Page 810 and 811:

Th or Eoc�1 � � � k1k2R2

- Page 812 and 813:

Th Independent Sources The procedur

- Page 814 and 815:

Th Solution: Steps 1 and 2 (Fig. 18

- Page 816 and 817:

Th The Norton equivalent circuit ap

- Page 818 and 819:

Th so Eg(1 � h) � Ig[R1 � (1

- Page 820 and 821:

Th + E = 9 V ∠ 0° - Z1Z 2 (10

- Page 822 and 823:

Th (8.54 V) 72.93 and Pmax � �

- Page 824 and 825:

Th ��� ��� ����

- Page 826 and 827:

Th For 100 W, Is � � Np �Ip

- Page 828 and 829:

Th Redrawing the network as shown i

- Page 830 and 831:

Th 0.5 -0.5 v s (volts) 0 T /2 T -T

- Page 832 and 833:

Th culation of �32.74° of Exampl

- Page 834 and 835:

Th FIG. 18.101 Using PSpice to dete

- Page 836 and 837:

Th FIG. 18.104 The output file for

- Page 838 and 839:

Th FIG. 18.107 Using PSpice to dete

- Page 840 and 841:

Th *5. Using superposition, find th

- Page 842 and 843:

Th PROBLEMS ⏐⏐⏐ 841 11. Find

- Page 844 and 845:

Th PROBLEMS ⏐⏐⏐ 843 20. Find

- Page 846 and 847:

Th PROBLEMS ⏐⏐⏐ 845 *40. Find

- Page 848 and 849:

Th GLOSSARY ⏐⏐⏐ 847 49. Using

- Page 850 and 851:

19 Power (ac) 19.1 INTRODUCTION The

- Page 852 and 853:

P q s Power delivered to element by

- Page 854 and 855:

P q s The reason for rating some el

- Page 856 and 857:

P q s If the average power is zero,

- Page 858 and 859:

P q s 2 V and QC � �� (VAR) (

- Page 860 and 861:

P q s j I 2 X L = Q L I 2 X C = Q C

- Page 862 and 863:

P q s Thus, PT 600 W Fp ���

- Page 864 and 865:

P q s Motor: h � Pi � � �45

- Page 866 and 867:

P q s + E = E ∠0° - I L Solving

- Page 868 and 869:

P q s The equivalent parallel load

- Page 870 and 871:

P q s As the name implies, power-fa

- Page 872 and 873:

P q s duced, the eddy current loss

- Page 874 and 875:

P q s The vast majority of generato

- Page 876 and 877:

P q s 349.2 kW � 240 kW � 109.2

- Page 878 and 879:

P q s Peak icon to the right of the

- Page 880 and 881:

P q s small region below the axis i

- Page 882 and 883:

P q s 6. For the circuit of Fig. 19

- Page 884 and 885:

P q s *14. For the circuit of Fig.

- Page 886:

P q s SECTION 19.10 Effective Resis

- Page 889 and 890:

888 ⏐⏐⏐ RESONANCE E s + - Sou

- Page 891 and 892:

890 ⏐⏐⏐ RESONANCE Q L = I 2 X

- Page 893 and 894:

892 ⏐⏐⏐ RESONANCE R R( f ) 0

- Page 895 and 896:

894 ⏐⏐⏐ RESONANCE f < f s: ne

- Page 897 and 898:

896 ⏐⏐⏐ RESONANCE Solving the

- Page 899 and 900:

898 ⏐⏐⏐ RESONANCE As Q s of t

- Page 901 and 902:

900 ⏐⏐⏐ RESONANCE b. Since Qs

- Page 903 and 904:

902 ⏐⏐⏐ RESONANCE I Z T Y T R

- Page 905 and 906:

904 ⏐⏐⏐ RESONANCE R l Z Tm Z

- Page 907 and 908:

906 ⏐⏐⏐ RESONANCE Setting the

- Page 909 and 910:

908 ⏐⏐⏐ RESONANCE Inductive R

- Page 911 and 912:

910 ⏐⏐⏐ RESONANCE For an idea

- Page 913 and 914:

912 ⏐⏐⏐ RESONANCE TABLE 20.1

- Page 915 and 916:

914 ⏐⏐⏐ RESONANCE Example 20.

- Page 917 and 918:

916 ⏐⏐⏐ RESONANCE I e. Ql ≥

- Page 919 and 920:

918 ⏐⏐⏐ RESONANCE Therefore,

- Page 921 and 922:

920 ⏐⏐⏐ RESONANCE Volume Full

- Page 923 and 924:

922 ⏐⏐⏐ RESONANCE bandwidth

- Page 925 and 926:

924 ⏐⏐⏐ RESONANCE FIG. 20.43

- Page 927 and 928:

926 ⏐⏐⏐ RESONANCE cursor esta

- Page 929 and 930:

928 ⏐⏐⏐ RESONANCE FIG. 20.48

- Page 931 and 932:

930 ⏐⏐⏐ RESONANCE I 2 mA IL I

- Page 933 and 934:

932 ⏐⏐⏐ RESONANCE ZT I = 5 mA

- Page 935 and 936:

934 ⏐⏐⏐ RESONANCE Z Tp GLOSSA

- Page 937 and 938:

936 ⏐⏐⏐ TRANSFORMERS + e p -

- Page 939 and 940:

938 ⏐⏐⏐ TRANSFORMERS L p = 20

- Page 941 and 942:

940 ⏐⏐⏐ TRANSFORMERS revealin

- Page 943 and 944:

942 ⏐⏐⏐ TRANSFORMERS Since th

- Page 945 and 946:

944 ⏐⏐⏐ TRANSFORMERS Solution

- Page 947 and 948:

946 ⏐⏐⏐ TRANSFORMERS Public a

- Page 949 and 950:

948 ⏐⏐⏐ TRANSFORMERS + v x -

- Page 951 and 952:

950 ⏐⏐⏐ TRANSFORMERS + V g -

- Page 953 and 954:

952 ⏐⏐⏐ TRANSFORMERS + V g -

- Page 955 and 956:

954 ⏐⏐⏐ TRANSFORMERS (a) (b)

- Page 957 and 958:

956 ⏐⏐⏐ TRANSFORMERS polariti

- Page 959 and 960:

958 ⏐⏐⏐ TRANSFORMERS Iron cor

- Page 961 and 962:

960 ⏐⏐⏐ TRANSFORMERS Primary

- Page 963 and 964:

962 ⏐⏐⏐ TRANSFORMERS Z i + E

- Page 965 and 966:

964 ⏐⏐⏐ TRANSFORMERS Source +

- Page 967 and 968:

966 ⏐⏐⏐ TRANSFORMERS ��

- Page 969 and 970:

968 ⏐⏐⏐ TRANSFORMERS insertio

- Page 971 and 972:

970 ⏐⏐⏐ TRANSFORMERS FIG. 21.

- Page 973 and 974:

972 ⏐⏐⏐ TRANSFORMERS + Vg = 2

- Page 975 and 976:

974 ⏐⏐⏐ TRANSFORMERS q = 1000

- Page 978 and 979:

22 Polyphase Systems 22.1 INTRODUCT

- Page 980 and 981:

0.866 E m(CN) 0.866 E m(BN) This is

- Page 982 and 983:

E BC The length x is C B + - E CN E

- Page 984 and 985:

B C E BC E CA (a) ⎪ ⎬ ⎪ ⎭ E

- Page 986 and 987:

. EL � �3�Ef � (1.73)(120 V

- Page 988 and 989:

E CA = 150 V ∠ v 3 b. Vf � EL.T

- Page 990 and 991:

I Bb I AC 30° 120° It can be show

- Page 992 and 993:

The phase voltages are Van � IanZ

- Page 994 and 995:

Power Factor The power factor of th

- Page 996 and 997:

Power Factor S T � 3S f � �3

- Page 998 and 999:

A + EAN - or EAN � IfZline � Vf

- Page 1000 and 1001:

methods of determining whether the

- Page 1002 and 1003:

IBb � Ibc � Iab � 8.32 A �

- Page 1004 and 1005:

or multiphase, result in a total lo

- Page 1006 and 1007:

40,000 V �120° � 33,200 V �

- Page 1008 and 1009:

7. For the system of Fig. 22.39, fi

- Page 1010 and 1011:

C 14. Repeat Problem 13 if the phas

- Page 1012 and 1013:

3-phase ∆-connected generator Pha

- Page 1014 and 1015:

*43. The Y-Y system of Fig. 22.48 h

- Page 1016:

GLOSSARY �-connected ac generator

- Page 1019 and 1020:

1018 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1021 and 1022:

1020 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1023 and 1024:

1022 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1025 and 1026:

1024 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1027 and 1028:

1026 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1029 and 1030:

1028 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1031 and 1032:

1030 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1033 and 1034:

1032 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1035 and 1036:

1034 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1037 and 1038:

1036 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1039 and 1040:

1038 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1041 and 1042:

1040 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1043 and 1044:

1042 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1045 and 1046:

1044 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1047 and 1048:

1046 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1049 and 1050:

1048 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1051 and 1052:

1050 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1053 and 1054:

1052 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1055 and 1056:

1054 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1057 and 1058:

1056 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1059 and 1060:

1058 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1061 and 1062:

1060 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1063 and 1064:

1062 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1065 and 1066:

1064 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1067 and 1068:

1066 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1069 and 1070:

1068 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1071 and 1072:

1070 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1073 and 1074:

1072 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1075 and 1076:

1074 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1077 and 1078:

1076 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1079 and 1080:

1078 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1081 and 1082:

1080 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1083 and 1084:

1082 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1085 and 1086:

1084 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1087 and 1088:

1086 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1089 and 1090:

1088 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1091 and 1092:

1090 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1093 and 1094:

1092 ⏐⏐⏐ DECIBELS, FILTERS, A

- Page 1095 and 1096:

1094 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1097 and 1098:

1096 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1099 and 1100:

1098 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1101 and 1102:

1100 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1103 and 1104:

1102 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1105 and 1106:

1104 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1107 and 1108:

1106 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1109 and 1110:

1108 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1111 and 1112:

1110 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1113 and 1114:

1112 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1115 and 1116:

1114 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1117 and 1118:

1116 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1119 and 1120:

1118 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1121 and 1122:

1120 ⏐⏐⏐ PULSE WAVEFORMS AND

- Page 1124 and 1125:

25 Nonsinusoidal Circuits 25.1 INTR

- Page 1126 and 1127:

NON Average Value: A 0 The dc term

- Page 1128 and 1129:

NON f(t) � �f � t � � T 2

- Page 1130 and 1131:

NON EXAMPLE 25.1 Determine which co

- Page 1132 and 1133:

NON 1 sin qt i t 1 (i = 0) FIG. 25.

- Page 1134 and 1135:

NON Vm 0 v 1 (a) and v � Vm�1

- Page 1136 and 1137:

NON v(a) � V 0 � V m1 sin a �

- Page 1138 and 1139:

NON EXAMPLE 25.7 The input to the c

- Page 1140 and 1141:

NON ZT1 � 6 ��j 37.7 ��38

- Page 1142 and 1143:

NON FIG. 25.28 Using PSpice to appl

- Page 1144 and 1145:

NON you can change the range to 0 H

- Page 1146 and 1147:

NON 9. Find the total average power

- Page 1148:

NON 24. Given any nonsinusoidal fun

- Page 1151 and 1152:

1150 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1153 and 1154:

1152 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1155 and 1156:

1154 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1157 and 1158:

1156 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1159 and 1160:

1158 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1161 and 1162:

1160 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1163 and 1164:

1162 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1165 and 1166:

1164 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1167 and 1168:

1166 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1169 and 1170:

1168 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1171 and 1172:

1170 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1173 and 1174:

1172 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1175 and 1176:

1174 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1177 and 1178:

1176 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1179 and 1180:

1178 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1181 and 1182:

1180 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1183 and 1184:

1182 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1185 and 1186:

1184 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1187 and 1188:

1186 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1189 and 1190:

1188 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1191 and 1192:

1190 ⏐⏐⏐ SYSTEM ANALYSIS: AN

- Page 1193 and 1194:

1192 Appendixes APPENDIX A PSpice,

- Page 1195 and 1196:

1194 ⏐⏐⏐ APPENDIXES A.3 Mathc

- Page 1197 and 1198:

1196 ⏐⏐⏐ APPENDIXES To Conver

- Page 1199 and 1200:

1198 Appendix C DETERMINANTS Determ

- Page 1201 and 1202:

1200 ⏐⏐⏐ APPENDIXES 2 3 �3

- Page 1203 and 1204:

1202 ⏐⏐⏐ APPENDIXES x � War

- Page 1205 and 1206:

1204 ⏐⏐⏐ APPENDIXES D Note th

- Page 1207 and 1208:

1206 Appendix D COLOR CODING OF MOL

- Page 1209 and 1210:

1208 Appendix F MAGNETIC PARAMETER

- Page 1211 and 1212:

1210 ⏐⏐⏐ APPENDIXES and the p

- Page 1213 and 1214:

1212 ⏐⏐⏐ APPENDIXES 3. (a) 16

- Page 1215 and 1216:

1214 ⏐⏐⏐ APPENDIXES (b) 50(1

- Page 1217 and 1218:

1216 ⏐⏐⏐ APPENDIXES (f) 300 W

- Page 1219 and 1220:

1218 ⏐⏐⏐ APPENDIXES 9. (a) E