Edwin Jan Klein - Universiteit Twente

Edwin Jan Klein - Universiteit Twente

Edwin Jan Klein - Universiteit Twente

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

123<br />

Fabrication<br />

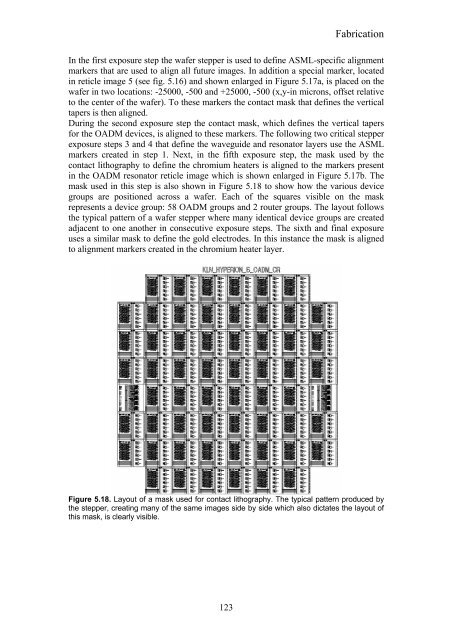

In the first exposure step the wafer stepper is used to define ASML-specific alignment<br />

markers that are used to align all future images. In addition a special marker, located<br />

in reticle image 5 (see fig. 5.16) and shown enlarged in Figure 5.17a, is placed on the<br />

wafer in two locations: -25000, -500 and +25000, -500 (x,y-in microns, offset relative<br />

to the center of the wafer). To these markers the contact mask that defines the vertical<br />

tapers is then aligned.<br />

During the second exposure step the contact mask, which defines the vertical tapers<br />

for the OADM devices, is aligned to these markers. The following two critical stepper<br />

exposure steps 3 and 4 that define the waveguide and resonator layers use the ASML<br />

markers created in step 1. Next, in the fifth exposure step, the mask used by the<br />

contact lithography to define the chromium heaters is aligned to the markers present<br />

in the OADM resonator reticle image which is shown enlarged in Figure 5.17b. The<br />

mask used in this step is also shown in Figure 5.18 to show how the various device<br />

groups are positioned across a wafer. Each of the squares visible on the mask<br />

represents a device group: 58 OADM groups and 2 router groups. The layout follows<br />

the typical pattern of a wafer stepper where many identical device groups are created<br />

adjacent to one another in consecutive exposure steps. The sixth and final exposure<br />

uses a similar mask to define the gold electrodes. In this instance the mask is aligned<br />

to alignment markers created in the chromium heater layer.<br />

Figure 5.18. Layout of a mask used for contact lithography. The typical pattern produced by<br />

the stepper, creating many of the same images side by side which also dictates the layout of<br />

this mask, is clearly visible.