- Page 1 and 2:

DENSELY INTEGRATED MICRORING- RESON

- Page 3 and 4:

DENSELY INTEGRATED MICRORING- RESON

- Page 5:

To my parents…

- Page 8 and 9:

esonators is limited by the spacing

- Page 10 and 11:

iv Samenvatting Dit proefschrift be

- Page 12 and 13:

schakelaar “aan” is, dan is de

- Page 14 and 15:

3.6.2 Overlap loss reduction.......

- Page 17 and 18:

Chapter 1 Introduction The devices

- Page 19 and 20:

1.2 Broadband to the home 3 Introdu

- Page 21 and 22:

1.3 Bringing Fiber to the Home 5 In

- Page 23 and 24:

Figure 1.5. The technological scope

- Page 25:

9 Introduction these basic paramete

- Page 28 and 29:

Chapter 2 2.1 Introduction Integrat

- Page 30 and 31:

Chapter 2 light Icav2 in the cavity

- Page 32 and 33:

Chapter 2 ∆ = ⎛ β r − β g

- Page 34 and 35:

Chapter 2 2.3.3 Combined model The

- Page 36 and 37:

Chapter 2 FC 4µ 1µ 2 ⋅ χr = 2

- Page 38 and 39:

Chapter 2 P Through /P In (dB) 0 -1

- Page 40 and 41:

Chapter 2 The figure shows that it

- Page 42 and 43:

Chapter 2 In − jϕr1 2 Figure 2.1

- Page 44 and 45:

Chapter 2 differences between the f

- Page 46 and 47:

Chapter 2 M = ⋅ FSR = N ⋅ FSR F

- Page 48 and 49:

Chapter 2 the heat will therefore f

- Page 50 and 51:

Chapter 2 index. Although this can

- Page 52 and 53:

Chapter 2 resonators for instance h

- Page 54 and 55:

Chapter 2 a rather complex MEMS bas

- Page 56 and 57:

Chapter 3 3.1 Introduction The most

- Page 58 and 59:

Chapter 3 3.2.1 Drop port on-resona

- Page 60 and 61:

Chapter 3 3.2.3 Filter bandwidth In

- Page 62 and 63:

Chapter 3 (resulting in a higher ba

- Page 64 and 65:

Chapter 3 Figure 3.11. Residual cha

- Page 66 and 67:

Chapter 3 3.3 Geometrical design ch

- Page 68 and 69:

Chapter 3 resonator and the port wa

- Page 70 and 71:

Chapter 3 Another important fact wh

- Page 72 and 73:

Chapter 3 The flowchart of the desi

- Page 74 and 75:

Chapter 3 While the resonator in th

- Page 76 and 77:

Chapter 3 3.6.1 Port waveguide and

- Page 78 and 79:

Chapter 3 overlap losses are only 0

- Page 80 and 81:

Chapter 3 3.7 Component design cons

- Page 82 and 83:

Chapter 3 By maximizing the power t

- Page 84 and 85:

Chapter 3 important, due to the fac

- Page 86 and 87:

Chapter 4 4.1 Introduction As was s

- Page 88 and 89:

Chapter 4 4.2.1 Transient response

- Page 90 and 91:

Chapter 4 Under the condition that

- Page 92 and 93: Chapter 4 Figure 4.4. Screenshot of

- Page 94 and 95: Chapter 4 The equations required to

- Page 96 and 97: Chapter 4 using an approach based o

- Page 98 and 99: Chapter 4 4.5.1 Architecture The Au

- Page 100 and 101: Chapter 4 4.5.2 Simulation method A

- Page 102 and 103: Chapter 4 Figure 4.9. A Primitive w

- Page 104 and 105: Chapter 4 Listing 4.3. Pseudo code

- Page 106 and 107: Chapter 4 Listing 4.4. Pseudo code

- Page 108 and 109: Chapter 4 simulated output spectra

- Page 110 and 111: Chapter 4 Figure 4.21. The reflecto

- Page 112 and 113: Chapter 4 P Drop /P In (dB) 0 -10 -

- Page 114 and 115: Chapter 4 Figure 4.27a. OADM with r

- Page 116 and 117: Chapter 4 will propagate through th

- Page 118 and 119: Chapter 4 As demonstrated by these

- Page 120 and 121: Chapter 4 What is more interesting

- Page 122 and 123: Chapter 4 method it does allow time

- Page 124 and 125: Chapter 4 complex than the interact

- Page 126 and 127: Chapter 5 5.1 Introduction The mate

- Page 128 and 129: Chapter 5 wafer is used (step 1). T

- Page 130 and 131: Chapter 5 range of 0.9 to 1.1 µm.

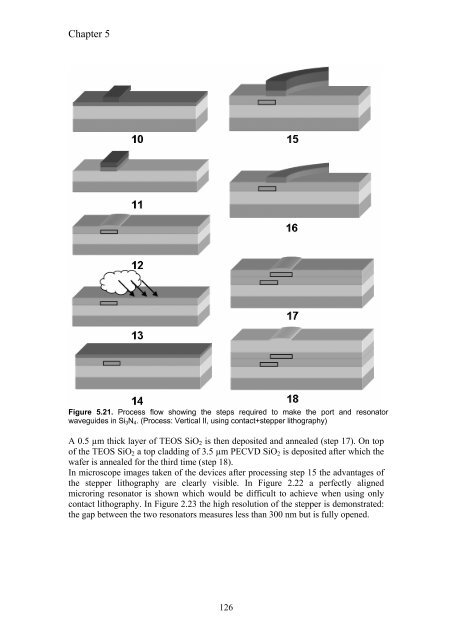

- Page 132 and 133: Chapter 5 The process flow with the

- Page 134 and 135: Chapter 5 5.3.3 Mask layout The big

- Page 136 and 137: Chapter 5 5.4. Fabrication and mask

- Page 138 and 139: Chapter 5 1. Definition of the vert

- Page 140 and 141: Chapter 5 5.4.2 Fabrication The fab

- Page 144 and 145: Chapter 5 removed using lift-off of

- Page 146 and 147: Chapter 6 6.1 Introduction About ha

- Page 148 and 149: Chapter 6 In early, comparatively s

- Page 150 and 151: Chapter 6 that the TEOS has a very

- Page 152 and 153: Chapter 6 The most important aspect

- Page 154 and 155: Chapter 6 6.2.3 Chromium heater des

- Page 156 and 157: Chapter 6 Therefore, even if the si

- Page 158 and 159: Chapter 6 Next, the heater was heat

- Page 160 and 161: Chapter 6 6.3 Characterization of s

- Page 162 and 163: Chapter 6 polarization maintaining

- Page 164 and 165: Chapter 6 the resonators in this gr

- Page 166 and 167: Chapter 6 Although the fitted coupl

- Page 168 and 169: Chapter 6 a cladding thickness of 3

- Page 170 and 171: Chapter 6 6.4 A wavelength selectiv

- Page 172 and 173: Chapter 6 A possible explanation fo

- Page 175 and 176: Chapter 7 Densely integrated device

- Page 177 and 178: Densely integrated devices for WDM-

- Page 179 and 180: Densely integrated devices for WDM-

- Page 181 and 182: Densely integrated devices for WDM-

- Page 183 and 184: 7.2.2 Spectral measurements Densely

- Page 185 and 186: Densely integrated devices for WDM-

- Page 187 and 188: Densely integrated devices for WDM-

- Page 189 and 190: Power Densely integrated devices fo

- Page 191 and 192: 7.3.4 Characterization Densely inte

- Page 193 and 194:

Densely integrated devices for WDM-

- Page 195 and 196:

Figure 7.31a. Eye pattern of the re

- Page 197:

Densely integrated devices for WDM-

- Page 200 and 201:

Chapter 8 8.1 Introduction In most

- Page 202 and 203:

Chapter 8 amount of power will be d

- Page 204 and 205:

Chapter 8 Another problem that may

- Page 206 and 207:

Chapter 8 halves that are each comp

- Page 209 and 210:

Chapter 9 Discussion and Conclusion

- Page 211 and 212:

Appendix A. Mason’s rule Several

- Page 213 and 214:

Appendix B. Crosstalk Derivation Th

- Page 215 and 216:

List of Acronyms ADSL - Asymmetric

- Page 217 and 218:

List of Symbols Q - Quality Factor

- Page 219 and 220:

Bibliography [1] Dan Schiller, “E

- Page 221 and 222:

Regions,” IEEE Photonics Technolo

- Page 223 and 224:

[66] B. E. Little, S. T. Chu, J. V.

- Page 225 and 226:

[97] H. Haeiwa, T. Naganawa and Y.

- Page 227 and 228:

[135] A. Driessen, D. H. Geuzebroek

- Page 229 and 230:

[165] T. Barwicz, M. R. Watts, M. A

- Page 231 and 232:

Publication List Patents (pending)

- Page 233 and 234:

R. Dekker, L.T.H.Hilderink, M.B.J.

- Page 235 and 236:

Networks (BB Photonics),” Interna

- Page 237 and 238:

Dankwoord/Acknowledgements Zo, dit

- Page 239:

223