II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OP-<str<strong>on</strong>g>II</str<strong>on</strong>g>-3<br />

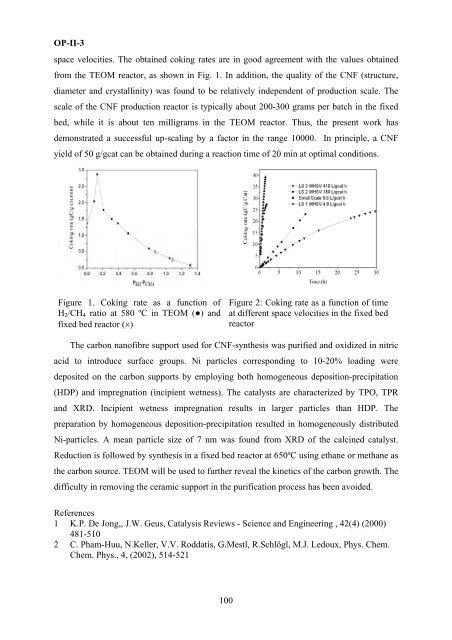

space velocities. The obtained coking rates are in good agreement with the values obtained<br />

from the TEOM reactor, as shown in Fig. 1. In additi<strong>on</strong>, the quality of the CNF (structure,<br />

diameter and crystallinity) was found to be relatively independent of producti<strong>on</strong> scale. The<br />

scale of the CNF producti<strong>on</strong> reactor is typically about 200-300 grams per batch in the fixed<br />

bed, while it is about ten milligrams in the TEOM reactor. Thus, the present work has<br />

dem<strong>on</strong>strated a successful up-scaling by a factor in the range 10000. In principle, a CNF<br />

yield of 50 g/gcat can be obtained during a reacti<strong>on</strong> time of 20 min at optimal c<strong>on</strong>diti<strong>on</strong>s.<br />

Figure 1. Coking rate as a functi<strong>on</strong> of<br />

H 2 /CH 4 ratio at 580 ºC in TEOM (●) and<br />

fixed bed reactor (×)<br />

Figure 2: Coking rate as a functi<strong>on</strong> of time<br />

at different space velocities in the fixed bed<br />

reactor<br />

The carb<strong>on</strong> nanofibre support used <strong>for</strong> CNF-synthesis was purified and oxidized in nitric<br />

acid to introduce surface groups. Ni particles corresp<strong>on</strong>ding to 10-20% loading were<br />

deposited <strong>on</strong> the carb<strong>on</strong> supports by employing both homogeneous depositi<strong>on</strong>-precipitati<strong>on</strong><br />

(HDP) and impregnati<strong>on</strong> (incipient wetness). The catalysts are characterized by TPO, TPR<br />

and XRD. Incipient wetness impregnati<strong>on</strong> results in larger particles than HDP. The<br />

preparati<strong>on</strong> by homogeneous depositi<strong>on</strong>-precipitati<strong>on</strong> resulted in homogeneously distributed<br />

Ni-particles. A mean particle size of 7 nm was found from XRD of the calcined catalyst.<br />

Reducti<strong>on</strong> is followed by synthesis in a fixed bed reactor at 650ºC using ethane or methane as<br />

the carb<strong>on</strong> source. TEOM will be used to further reveal the kinetics of the carb<strong>on</strong> growth. The<br />

difficulty in removing the ceramic support in the purificati<strong>on</strong> process has been avoided.<br />

References<br />

1 K.P. De J<strong>on</strong>g,, J.W. Geus, <strong>Catalysis</strong> Reviews - Science and Engineering , 42(4) (2000)<br />

481-510<br />

2 C. Pham-Huu, N.Keller, V.V. Roddatis, G.Mestl, R.Schlögl, M.J. Ledoux, Phys. Chem.<br />

Chem. Phys., 4, (2002), 514-521<br />

100