II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PP-I-20<br />

time <strong>on</strong> stream increased from 1 to 20 h and graphitic nitrogen became the main state in<br />

N-CNF produced after 20 h.<br />

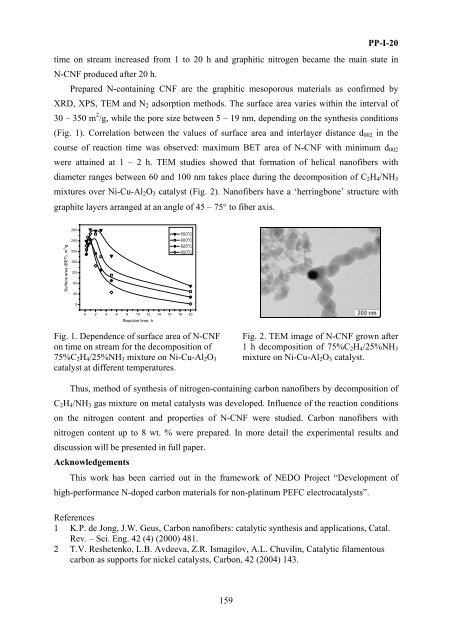

Prepared N-c<strong>on</strong>taining CNF are the graphitic mesoporous materials as c<strong>on</strong>firmed by<br />

XRD, XPS, TEM and N 2 adsorpti<strong>on</strong> methods. The surface area varies within the interval of<br />

30 – 350 m 2 /g, while the pore size between 5 – 19 nm, depending <strong>on</strong> the synthesis c<strong>on</strong>diti<strong>on</strong>s<br />

(Fig. 1). Correlati<strong>on</strong> between the values of surface area and interlayer distance d 002 in the<br />

course of reacti<strong>on</strong> time was observed: maximum BET area of N-CNF with minimum d 002<br />

were attained at 1 – 2 h. TEM studies showed that <strong>for</strong>mati<strong>on</strong> of helical nanofibers with<br />

diameter ranges between 60 and 100 nm takes place during the decompositi<strong>on</strong> of C 2 H 4 /NH 3<br />

mixtures over Ni-Cu-Al 2 O 3 catalyst (Fig. 2). Nanofibers have a ‘herringb<strong>on</strong>e’ structure with<br />

graphite layers arranged at an angle of 45 – 75° to fiber axis.<br />

Surface area (BET), m 2 /g<br />

280<br />

240<br />

200<br />

160<br />

120<br />

80<br />

40<br />

550 о С<br />

600 о С<br />

625 о С<br />

650 о С<br />

0<br />

0 2 4 6 8 10 12 14 16 18 20<br />

Reacti<strong>on</strong> time, h<br />

Fig. 1. Dependence of surface area of N-CNF<br />

<strong>on</strong> time <strong>on</strong> stream <strong>for</strong> the decompositi<strong>on</strong> of<br />

75%C 2 H 4 /25%NH 3 mixture <strong>on</strong> Ni-Cu-Al 2 O 3<br />

catalyst at different temperatures.<br />

Fig. 2. TEM image of N-CNF grown after<br />

1 h decompositi<strong>on</strong> of 75%C 2 H 4 /25%NH 3<br />

mixture <strong>on</strong> Ni-Cu-Al 2 O 3 catalyst.<br />

Thus, method of synthesis of nitrogen-c<strong>on</strong>taining carb<strong>on</strong> nanofibers by decompositi<strong>on</strong> of<br />

C 2 H 4 /NH 3 gas mixture <strong>on</strong> metal catalysts was developed. Influence of the reacti<strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s<br />

<strong>on</strong> the nitrogen c<strong>on</strong>tent and properties of N-CNF were studied. Carb<strong>on</strong> nanofibers with<br />

nitrogen c<strong>on</strong>tent up to 8 wt. % were prepared. In more detail the experimental results and<br />

discussi<strong>on</strong> will be presented in full paper.<br />

Acknowledgements<br />

This work has been carried out in the framework of NEDO Project “Development of<br />

high-per<strong>for</strong>mance N-doped carb<strong>on</strong> materials <strong>for</strong> n<strong>on</strong>-platinum PEFC electrocatalysts”.<br />

References<br />

1 K.P. de J<strong>on</strong>g, J.W. Geus, Carb<strong>on</strong> nanofibers: catalytic synthesis and applicati<strong>on</strong>s, Catal.<br />

Rev. – Sci. Eng. 42 (4) (2000) 481.<br />

2 T.V. Reshetenko, L.B. Avdeeva, Z.R. Ismagilov, A.L. Chuvilin, Catalytic filamentous<br />

carb<strong>on</strong> as supports <strong>for</strong> nickel catalysts, Carb<strong>on</strong>, 42 (2004) 143.<br />

159