II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PP-I-33<br />

c<strong>on</strong>sistence of the process, and the recovering in the surface area, which is <strong>on</strong>e of the most<br />

important factors affecting the activity of these catalysts.<br />

The regenerati<strong>on</strong> tests have been carried out in a bench scale fluidized bed reactor. The<br />

following activati<strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s have been studied: (1) activating agent: CO 2 (2) activati<strong>on</strong><br />

temperature: 900, 925 and 950º C; (3) carb<strong>on</strong> residence time: 2 and 4 hours.<br />

Table 1 shows the results obtained<br />

Catalyst Burn off (%) BET Area (m 2 /g)<br />

CG Norit fresh - 1300<br />

<strong>for</strong> the Activated Carb<strong>on</strong>-CG<br />

CG Norit deactivated - 111 NORIT. A lineal relati<strong>on</strong>ship<br />

CG Norit regenerated<br />

CG Norit regenerated<br />

CG Norit regenerated<br />

925ºC 2 hours 30 1287<br />

900ºC 2 hours<br />

900ºC 4 hours<br />

CG Norit regenerated<br />

5<br />

15<br />

303,6<br />

606,4<br />

925ºC 4 hours 57 1860<br />

between % of weight loss (% of<br />

burn off) and surface area can be<br />

observed. A compromise between<br />

% burn off and surface area<br />

recovered must be accomplished in<br />

order to assure that the process is self-c<strong>on</strong>sistent. For this reas<strong>on</strong>, the optimum regenerati<strong>on</strong><br />

c<strong>on</strong>diti<strong>on</strong>s selected were 900ºC- 4 hours and 925ºC- 2 hours. In both c<strong>on</strong>diti<strong>on</strong>s, the weight<br />

loss is under 30%, taking into account that after each reacti<strong>on</strong> step, 400mg/g carb<strong>on</strong> is<br />

deposited, which corresp<strong>on</strong>ds to a 40% of the catalyst mass. The recovering of the surface<br />

area is over 50% in both c<strong>on</strong>diti<strong>on</strong>s.<br />

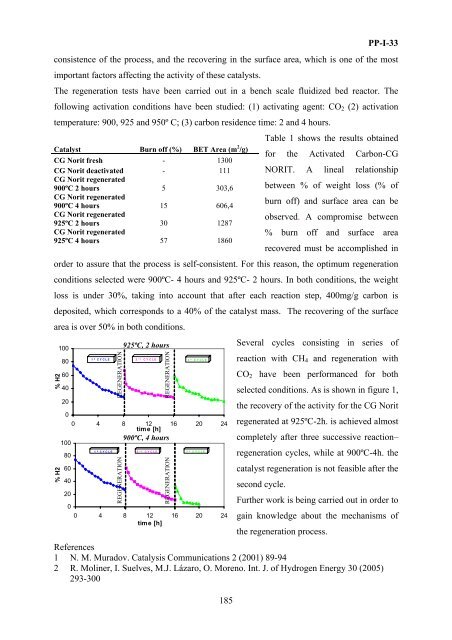

% H2<br />

% H2<br />

100<br />

80<br />

60<br />

40<br />

20<br />

REGENERATION<br />

REGENERATION<br />

925ºC, , 2 hours<br />

REGENERATION<br />

1 st CYCLE 2 nd CYCLE 3 th CYCLE<br />

0<br />

0 4 900ºC, 8 412hours<br />

16 20 24<br />

time [h]<br />

900ºC, 4 hours<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

REGENERATION<br />

ERATION<br />

REGENERATION<br />

1 st CYCLE 2 nd CYCLE 3 th CYCLE<br />

REGEN<br />

REGENER<br />

0 4 8 12 16 20 24<br />

time [h]<br />

Several cycles c<strong>on</strong>sisting in series of<br />

reacti<strong>on</strong> with CH 4 and regenerati<strong>on</strong> with<br />

CO 2 have been per<strong>for</strong>manced <strong>for</strong> both<br />

selected c<strong>on</strong>diti<strong>on</strong>s. As is shown in figure 1,<br />

the recovery of the activity <strong>for</strong> the CG Norit<br />

regenerated at 925ºC-2h. is achieved almost<br />

completely after three successive reacti<strong>on</strong>–<br />

regenerati<strong>on</strong> cycles, while at 900ºC-4h. the<br />

catalyst regenerati<strong>on</strong> is not feasible after the<br />

sec<strong>on</strong>d cycle.<br />

Further work is being carried out in order to<br />

gain knowledge about the mechanisms of<br />

the regenerati<strong>on</strong> process.<br />

References<br />

1 N. M. Muradov. <strong>Catalysis</strong> Communicati<strong>on</strong>s 2 (2001) 89-94<br />

2 R. Moliner, I. Suelves, M.J. Lázaro, O. Moreno. Int. J. of Hydrogen Energy 30 (2005)<br />

293-300<br />

185