II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OP-<str<strong>on</strong>g>II</str<strong>on</strong>g>-10<br />

The dehydrogenati<strong>on</strong> reacti<strong>on</strong> of decalin was tested m<strong>on</strong>itoring the hydrogen evoluti<strong>on</strong><br />

volumetrically in a batch reactor at atmospheric pressure, under nitrogen atmosphere, heating<br />

over the boiling point of the reactant and refluxing. The tested factors were the percentage of<br />

Pt in the catalyst (1%, 3%), the temperature (513K, 533K) and the decalin/catalyst ratio (2,<br />

2.7, 3.3 and 4 ml/g).<br />

Results and discussi<strong>on</strong><br />

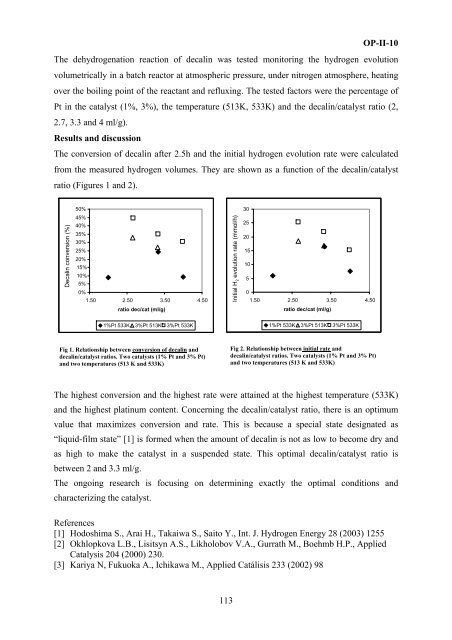

The c<strong>on</strong>versi<strong>on</strong> of decalin after 2.5h and the initial hydrogen evoluti<strong>on</strong> rate were calculated<br />

from the measured hydrogen volumes. They are shown as a functi<strong>on</strong> of the decalin/catalyst<br />

ratio (Figures 1 and 2).<br />

50%<br />

30<br />

Decalin c<strong>on</strong>versi<strong>on</strong> (%)<br />

45%<br />

40%<br />

35%<br />

30%<br />

25%<br />

20%<br />

15%<br />

10%<br />

5%<br />

0%<br />

1.50 2.50 3.50 4.50<br />

Initial H 2 evoluti<strong>on</strong> rate (mmol/h)<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

1.50 2.50 3.50 4.50<br />

ratio dec/cat (ml/g)<br />

ratio dec/cat (ml/g)<br />

1%Pt 533K 3%Pt 513K 3%Pt 533K<br />

1%Pt 533K 3%Pt 513K 3%Pt 533K<br />

Fig 1. Relati<strong>on</strong>ship between c<strong>on</strong>versi<strong>on</strong> of decalin and<br />

decalin/catalyst ratios. Two catalysts (1% Pt and 3% Pt)<br />

and two temperatures (513 K and 533K)<br />

Fig 2. Relati<strong>on</strong>ship between initial rate and<br />

decalin/catalyst ratios. Two catalysts (1% Pt and 3% Pt)<br />

and two temperatures (513 K and 533K)<br />

The highest c<strong>on</strong>versi<strong>on</strong> and the highest rate were attained at the highest temperature (533K)<br />

and the highest platinum c<strong>on</strong>tent. C<strong>on</strong>cerning the decalin/catalyst ratio, there is an optimum<br />

value that maximizes c<strong>on</strong>versi<strong>on</strong> and rate. This is because a special state designated as<br />

“liquid-film state” [1] is <strong>for</strong>med when the amount of decalin is not as low to become dry and<br />

as high to make the catalyst in a suspended state. This optimal decalin/catalyst ratio is<br />

between 2 and 3.3 ml/g.<br />

The <strong>on</strong>going research is focusing <strong>on</strong> determining exactly the optimal c<strong>on</strong>diti<strong>on</strong>s and<br />

characterizing the catalyst.<br />

References<br />

[1] Hodoshima S., Arai H., Takaiwa S., Saito Y., Int. J. Hydrogen Energy 28 (2003) 1255<br />

[2] Okhlopkova L.B., Lisitsyn A.S., Likholobov V.A., Gurrath M., Boehmb H.P., Applied<br />

<strong>Catalysis</strong> 204 (2000) 230.<br />

[3] Kariya N, Fukuoka A., Ichikawa M., Applied Catálisis 233 (2002) 98<br />

113