II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PP-<str<strong>on</strong>g>II</str<strong>on</strong>g>-18<br />

Thus, the object of this research was to develop new effective catalysts, based of carb<strong>on</strong><br />

material sibunit <strong>for</strong> acetaldehyde synthesis by ethanol dehydrogenati<strong>on</strong>.<br />

Our previous researches have shown that based <strong>on</strong> sibunit copper-c<strong>on</strong>taining catalysts are<br />

the most effective <strong>for</strong> acetaldehyde synthesis. The maximum yield of acetaldehyde reached<br />

69,2% at 375 0 C at the presence of catalyst 3%Cu/sibunit. However such systems were<br />

unstable in the process c<strong>on</strong>diti<strong>on</strong>s. Activity of this catalyst sharply decreased at high<br />

temperatures (above 400 0 C). One of the ways of increase of catalysts stability is introducti<strong>on</strong><br />

of promoti<strong>on</strong>al additives, which interfere of copper sintering. In this c<strong>on</strong>necti<strong>on</strong> we<br />

investigated expediency of introducti<strong>on</strong> of Cr 2 O 3 additives in copper c<strong>on</strong>taining catalysts.<br />

Our studies have shown, that chrome oxide possesses of catalytic activity in ethanol<br />

trans<strong>for</strong>mati<strong>on</strong>. C<strong>on</strong>versi<strong>on</strong> of ethanol was 58% at 500 0 C at the presence of catalyst<br />

3%Cr 2 O 3 /sibunit and the main products were acetaldehyde and ethylene. Thus, the received<br />

results have allowed to assume, that the additive of small amounts of Cr 2 O 3 can increase<br />

activity of the catalyst. For acknowledgement of this assumpti<strong>on</strong> we have tested the samples<br />

of copper catalysts which c<strong>on</strong>tain Cr 2 O 3 additives in different quantities.<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Cu<br />

Cu-Cr2O3<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

350 375 400 425 450 500<br />

350 375 400 425 450 500<br />

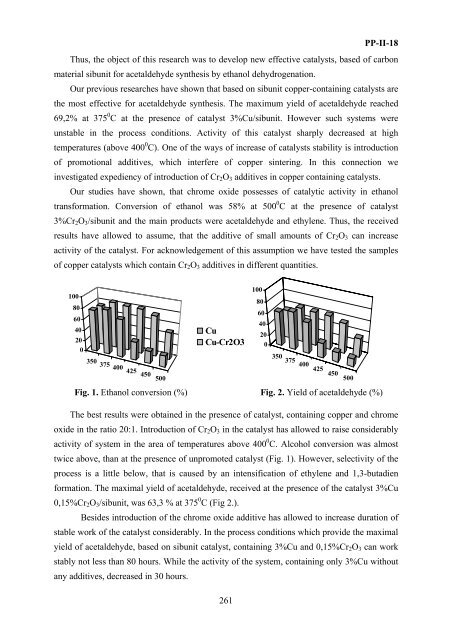

Fig. 1. Ethanol c<strong>on</strong>versi<strong>on</strong> (%) Fig. 2. Yield of acetaldehyde (%)<br />

The best results were obtained in the presence of catalyst, c<strong>on</strong>taining copper and chrome<br />

oxide in the ratio 20:1. Introducti<strong>on</strong> of Cr 2 O 3 in the catalyst has allowed to raise c<strong>on</strong>siderably<br />

activity of system in the area of temperatures above 400 0 C. Alcohol c<strong>on</strong>versi<strong>on</strong> was almost<br />

twice above, than at the presence of unpromoted catalyst (Fig. 1). However, selectivity of the<br />

process is a little below, that is caused by an intensificati<strong>on</strong> of ethylene and 1,3-butadien<br />

<strong>for</strong>mati<strong>on</strong>. The maximal yield of acetaldehyde, received at the presence of the catalyst 3%Cu<br />

0,15%Cr 2 O 3 /sibunit, was 63,3 % at 375 0 C (Fig 2.).<br />

Besides introducti<strong>on</strong> of the chrome oxide additive has allowed to increase durati<strong>on</strong> of<br />

stable work of the catalyst c<strong>on</strong>siderably. In the process c<strong>on</strong>diti<strong>on</strong>s which provide the maximal<br />

yield of acetaldehyde, based <strong>on</strong> sibunit catalyst, c<strong>on</strong>taining 3%Cu and 0,15%Cr 2 O 3 can work<br />

stably not less than 80 hours. While the activity of the system, c<strong>on</strong>taining <strong>on</strong>ly 3%Cu without<br />

any additives, decreased in 30 hours.<br />

261