II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

II International Symposium on Carbon for Catalysis ABSTRACTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PP-I-34<br />

practically identical [2], it is possible to determine the pore volume inside the aggregates<br />

according to the quantity absorbed DBP with corrective factors.<br />

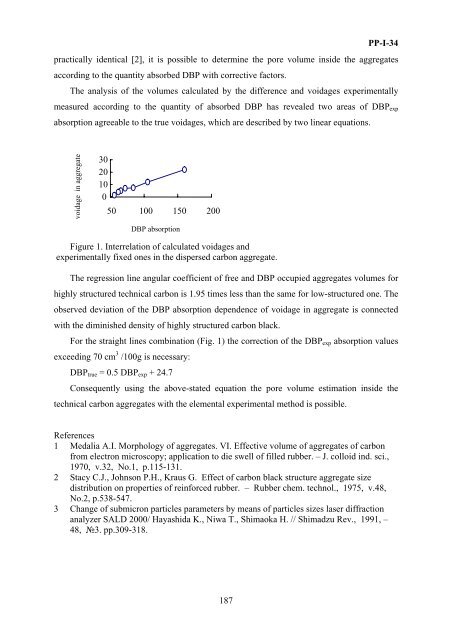

The analysis of the volumes calculated by the difference and voidages experimentally<br />

measured according to the quantity of absorbed DBP has revealed two areas of DBP ехр<br />

absorpti<strong>on</strong> agreeable to the true voidages, which are described by two linear equati<strong>on</strong>s.<br />

voidage in aggregate<br />

30<br />

20<br />

10<br />

0<br />

50 100 150 200<br />

DBP absorpti<strong>on</strong><br />

Figure 1. Interrelati<strong>on</strong> of calculated voidages and<br />

experimentally fixed <strong>on</strong>es in the dispersed carb<strong>on</strong> aggregate.<br />

The regressi<strong>on</strong> line angular coefficient of free and DBP occupied aggregates volumes <strong>for</strong><br />

highly structured technical carb<strong>on</strong> is 1.95 times less than the same <strong>for</strong> low-structured <strong>on</strong>e. The<br />

observed deviati<strong>on</strong> of the DBP absorpti<strong>on</strong> dependence of voidage in aggregate is c<strong>on</strong>nected<br />

with the diminished density of highly structured carb<strong>on</strong> black.<br />

For the straight lines combinati<strong>on</strong> (Fig. 1) the correcti<strong>on</strong> of the DBP exp absorpti<strong>on</strong> values<br />

exceeding 70 cm 3 /100g is necessary:<br />

DBP true = 0.5 DBP exp + 24.7<br />

C<strong>on</strong>sequently using the above-stated equati<strong>on</strong> the pore volume estimati<strong>on</strong> inside the<br />

technical carb<strong>on</strong> aggregates with the elemental experimental method is possible.<br />

References<br />

1 Medalia A.I. Morphology of aggregates. VI. Effective volume of aggregates of carb<strong>on</strong><br />

from electr<strong>on</strong> microscopy; applicati<strong>on</strong> to die swell of filled rubber. – J. colloid ind. sci.,<br />

1970, v.32, No.1, p.115-131.<br />

2 Stacy C.J., Johns<strong>on</strong> P.H., Kraus G. Effect of carb<strong>on</strong> black structure aggregate size<br />

distributi<strong>on</strong> <strong>on</strong> properties of rein<strong>for</strong>ced rubber. – Rubber chem. technol., 1975, v.48,<br />

No.2, p.538-547.<br />

3 Change of submicr<strong>on</strong> particles parameters by means of particles sizes laser diffracti<strong>on</strong><br />

analyzer SALD 2000/ Hayashida K., Niwa T., Shimaoka H. // Shimadzu Rev., 1991, –<br />

48, №3. pp.309-318.<br />

187