272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GENERAL INFORMATION<br />

Install new piston rings whenever the engine is<br />

disassembled for major servicing or overhaul,<br />

providing that cylinder bores are within specification.<br />

<br />

1. Remove any carbon or ridge at the top of the<br />

cylinder bore. This will prevent breaking the<br />

rings when removing the piston and connecting<br />

rod from the engine.<br />

2. Remove the connecting rod cap. Push the<br />

piston and connecting rod out through the top of<br />

the cylinder.<br />

3. Measure cylinder bores before checking pistons<br />

and rings. If cylinder bores require re-sizing it is<br />

not necessary to check pistons and rings, since<br />

a new oversized piston assembly will be used.<br />

Resize a cylinder bore if it is more than 0.003” (0.08<br />

mm) oversize, or 0.0015” (0.04 mm) out of round.<br />

Disassemble<br />

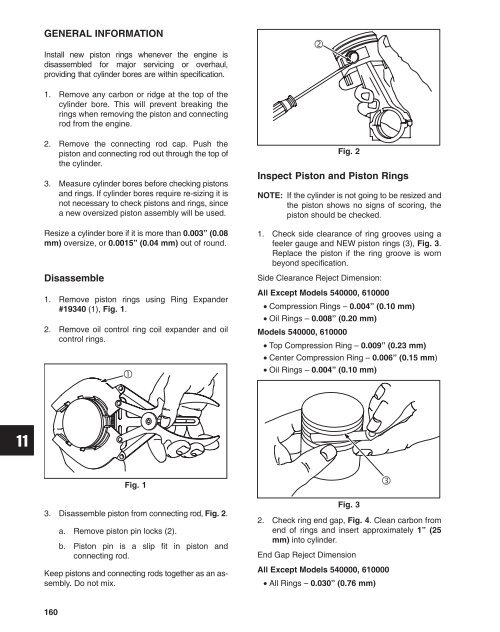

1. Remove piston rings using Ring Expander<br />

#19340 (1), Fig. 1.<br />

2. Remove oil control ring coil expander and oil<br />

control rings.<br />

<br />

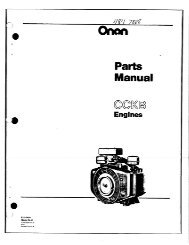

Fig. 2<br />

Inspect Piston and Piston Rings<br />

NOTE: If the cylinder is not going to be resized and<br />

the piston shows no signs of scoring, the<br />

piston should be checked.<br />

1. Check side clearance of ring grooves using a<br />

feeler gauge and NEW piston rings (3), Fig. 3.<br />

Replace the piston if the ring groove is worn<br />

beyond specification.<br />

Side Clearance Reject Dimension:<br />

All Except Models 540000, 610000<br />

• Compression Rings – 0.004” (0.10 mm)<br />

• Oil Rings – 0.008” (0.20 mm)<br />

Models 540000, 610000<br />

• Top Compression Ring – 0.009” (0.23 mm)<br />

• Center Compression Ring – 0.006” (0.15 mm)<br />

• Oil Rings – 0.004” (0.10 mm)<br />

Fig. 1<br />

3. Disassemble piston from connecting rod, Fig. 2.<br />

a. Remove piston pin locks (2).<br />

b. Piston pin is a slip fit in piston and<br />

connecting rod.<br />

Keep pistons and connecting rods together as an assembly.<br />

Do not mix.<br />

Fig. 3<br />

<br />

2. Check ring end gap, Fig. 4. Clean carbon from<br />

end of rings and insert approximately 1” (25<br />

mm) into cylinder.<br />

End Gap Reject Dimension<br />

All Except Models 540000, 610000<br />

• All Rings – 0.030” (0.76 mm)<br />

160