272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Most complaints concerning engine operation can be<br />

classified as one or more of the following:<br />

1. Will not start<br />

2. Hard starting<br />

3. Lack of power<br />

<br />

<br />

4. Runs rough<br />

5. Vibration<br />

6. Overheating<br />

7. High oil consumption<br />

<br />

<br />

NOTE: What appears to be an engine problem may<br />

actually be the fault of the powered<br />

equipment. If equipment is suspect, see<br />

Equipment Affecting Engine Operation.<br />

SYSTEMATIC CHECK<br />

A systematic check of the engine can be performed<br />

in minutes, and is an accurate method of<br />

determining the source of the problem. The basic<br />

procedure is the same for all engine models.<br />

Variations, by model, will be shown under the subject<br />

heading. If the engine will not start and the cause is<br />

not apparent, perform a systematic check in the<br />

following order:<br />

1. Ignition<br />

2. Carburetion<br />

3. Compression<br />

Ignition<br />

Test Using Electric Starter<br />

NOTE: Magnetron ignition systems require a<br />

minimum of 350 RPM to produce spark.<br />

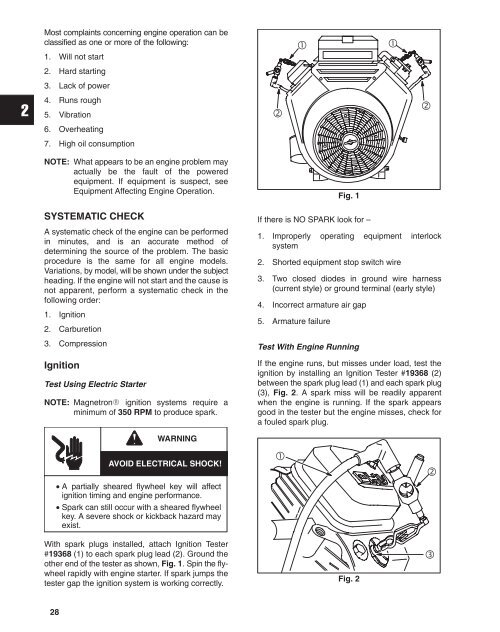

Fig. 1<br />

If there is NO SPARK look for –<br />

1. Improperly operating equipment interlock<br />

system<br />

2. Shorted equipment stop switch wire<br />

3. Two closed diodes in ground wire harness<br />

(current style) or ground terminal (early style)<br />

4. Incorrect armature air gap<br />

5. Armature failure<br />

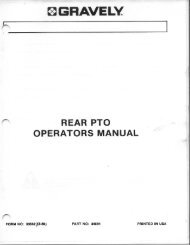

Test With Engine Running<br />

If the engine runs, but misses under load, test the<br />

ignition by installing an Ignition Tester #19368 (2)<br />

between the spark plug lead (1) and each spark plug<br />

(3), Fig. 2. A spark miss will be readily apparent<br />

when the engine is running. If the spark appears<br />

good in the tester but the engine misses, check for<br />

a fouled spark plug.<br />

WARNING<br />

AVOID ELECTRICAL SHOCK!<br />

• A partially sheared flywheel key will affect<br />

ignition timing and engine performance.<br />

• Spark can still occur with a sheared flywheel<br />

key. A severe shock or kickback hazard may<br />

exist.<br />

<br />

<br />

With spark plugs installed, attach Ignition Tester<br />

#19368 (1) to each spark plug lead (2). Ground the<br />

other end of the tester as shown, Fig. 1. Spin the flywheel<br />

rapidly with engine starter. If spark jumps the<br />

tester gap the ignition system is working correctly.<br />

Fig. 2<br />

<br />

28