272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cylinder</strong> Leakdown Test<br />

Use a leakdown tester to test the sealing capability<br />

of each cylinder. Follow the instructions for the leakdown<br />

tester you are using to determine the likely<br />

problem area(s).<br />

<br />

1. Run engine for 5 minutes allowing engine to<br />

reach operating temperature.<br />

NOTE: If the engine is cold or cannot be started, air<br />

flow may be higher (gauge readings lower)<br />

because compression components are not<br />

at normal operating temperatures.<br />

2. Remove spark plug from engine. Disconnect<br />

crankcase breather tube.<br />

3. Rotate crankshaft in direction of operation until<br />

piston is at Top Dead Center (TDC) of the compression<br />

stroke.<br />

4. Hold flywheel nut with socket and breaker bar.<br />

NOTE: Hold the crankshaft with the piston at TDC<br />

to minimize the chance of rotation.<br />

CAUTION<br />

AVOID INJURY!<br />

• Injury could occur if the crankshaft is<br />

allowed to rotate or if the engine is not<br />

securely fastened to a stand or to the<br />

application.<br />

5. Connect tester to a shop air source with<br />

minimum air pressure of 70 psi (480 kPa).<br />

6. Install outlet hose into spark plug hole of cylinder<br />

being tested. Insure O-ring is seated to prevent<br />

air leak at spark plug hole. Connect other end to<br />

tester.<br />

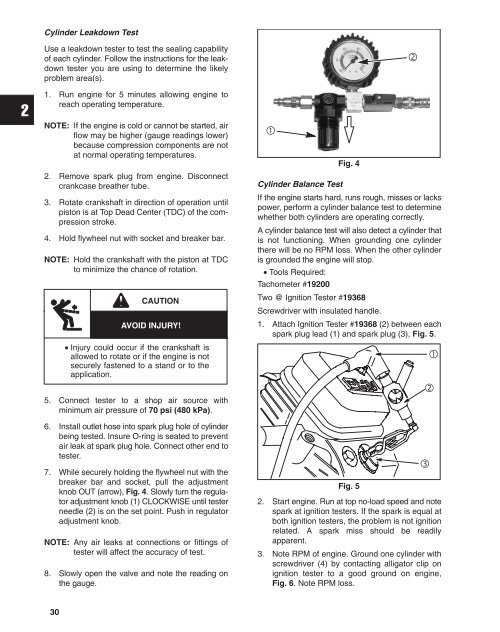

7. While securely holding the flywheel nut with the<br />

breaker bar and socket, pull the adjustment<br />

knob OUT (arrow), Fig. 4. Slowly turn the regulator<br />

adjustment knob (1) CLOCKWISE until tester<br />

needle (2) is on the set point. Push in regulator<br />

adjustment knob.<br />

NOTE: Any air leaks at connections or fittings of<br />

tester will affect the accuracy of test.<br />

8. Slowly open the valve and note the reading on<br />

the gauge.<br />

<br />

Fig. 4<br />

<strong>Cylinder</strong> Balance Test<br />

If the engine starts hard, runs rough, misses or lacks<br />

power, perform a cylinder balance test to determine<br />

whether both cylinders are operating correctly.<br />

A cylinder balance test will also detect a cylinder that<br />

is not functioning. When grounding one cylinder<br />

there will be no RPM loss. When the other cylinder<br />

is grounded the engine will stop.<br />

• Tools Required:<br />

Tachometer #19200<br />

Two @ Ignition Tester #19368<br />

Screwdriver with insulated handle.<br />

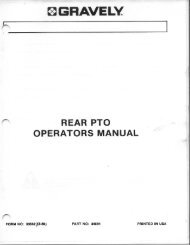

1. Attach Ignition Tester #19368 (2) between each<br />

spark plug lead (1) and spark plug (3), Fig. 5.<br />

Fig. 5<br />

<br />

<br />

<br />

2. Start engine. Run at top no-load speed and note<br />

spark at ignition testers. If the spark is equal at<br />

both ignition testers, the problem is not ignition<br />

related. A spark miss should be readily<br />

apparent.<br />

3. Note RPM of engine. Ground one cylinder with<br />

screwdriver (4) by contacting alligator clip on<br />

ignition tester to a good ground on engine,<br />

Fig. 6. Note RPM loss.<br />

30