272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

272144 Vanguard Twin Cylinder OHV BRIGGS & STRATTON.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

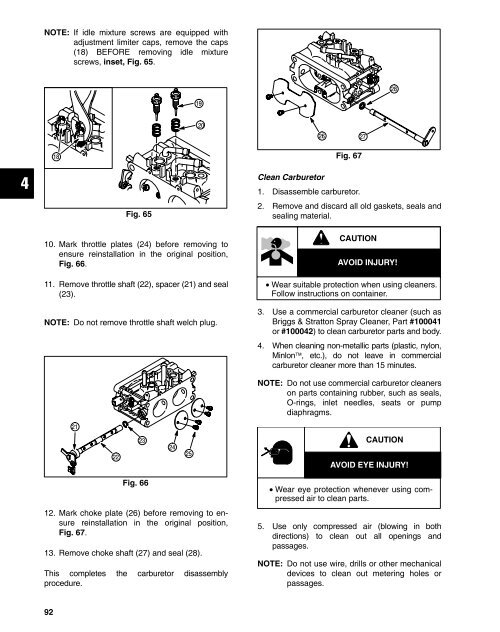

NOTE: If idle mixture screws are equipped with<br />

adjustment limiter caps, remove the caps<br />

(18) BEFORE removing idle mixture<br />

screws, inset, Fig. 65.<br />

<br />

<br />

<br />

<br />

<br />

<br />

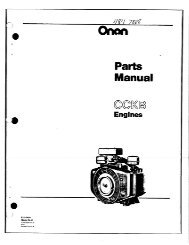

Fig. 67<br />

Fig. 65<br />

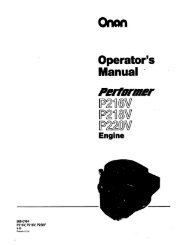

10. Mark throttle plates (24) before removing to<br />

ensure reinstallation in the original position,<br />

Fig. 66.<br />

11. Remove throttle shaft (22), spacer (21) and seal<br />

(23).<br />

NOTE: Do not remove throttle shaft welch plug.<br />

Clean Carburetor<br />

1. Disassemble carburetor.<br />

2. Remove and discard all old gaskets, seals and<br />

sealing material.<br />

CAUTION<br />

AVOID INJURY!<br />

• Wear suitable protection when using cleaners.<br />

Follow instructions on container.<br />

3. Use a commercial carburetor cleaner (such as<br />

Briggs & Stratton Spray Cleaner, Part #100041<br />

or #100042) to clean carburetor parts and body.<br />

4. When cleaning non-metallic parts (plastic, nylon,<br />

Minlon, etc.), do not leave in commercial<br />

carburetor cleaner more than 15 minutes.<br />

NOTE: Do not use commercial carburetor cleaners<br />

on parts containing rubber, such as seals,<br />

O-rings, inlet needles, seats or pump<br />

diaphragms.<br />

<br />

<br />

<br />

<br />

<br />

CAUTION<br />

AVOID EYE INJURY!<br />

Fig. 66<br />

12. Mark choke plate (26) before removing to ensure<br />

reinstallation in the original position,<br />

Fig. 67.<br />

13. Remove choke shaft (27) and seal (28).<br />

This completes the carburetor disassembly<br />

procedure.<br />

• Wear eye protection whenever using compressed<br />

air to clean parts.<br />

5. Use only compressed air (blowing in both<br />

directions) to clean out all openings and<br />

passages.<br />

NOTE: Do not use wire, drills or other mechanical<br />

devices to clean out metering holes or<br />

passages.<br />

92