Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5-4-3 Electronic Gear<br />

Electronic gear ratio parameter can be used to scale the command output pulse.<br />

This would be useful in transmission applications where move distance per move command pulse<br />

has to be scaled due to mechanical requirements.<br />

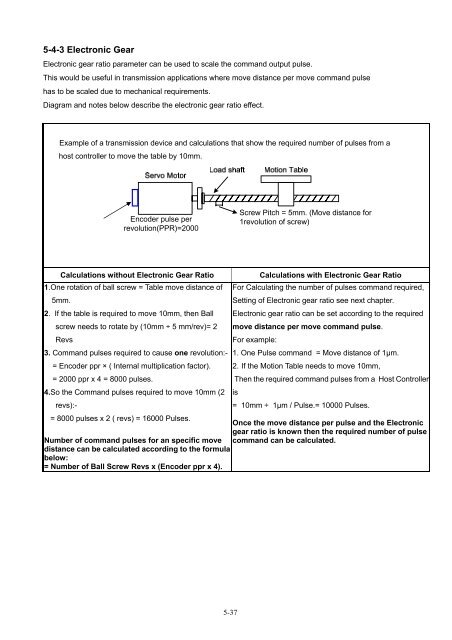

Diagram and notes below describe the electronic gear ratio effect.<br />

Example of a transmission device and calculations that show the required number of pulses from a<br />

host controller to move the table by 10mm.<br />

Encoder pulse per<br />

revolution(PPR)=2000<br />

Screw Pitch = 5mm. (Move distance for<br />

1revolution of screw)<br />

Calculations without Electronic Gear Ratio<br />

Calculations with Electronic Gear Ratio<br />

1.One rotation of ball screw = Table move distance of For Calculating the number of pulses command required,<br />

5mm.<br />

Setting of Electronic gear ratio see next chapter.<br />

2. If the table is required to move 10mm, then Ball Electronic gear ratio can be set according to the required<br />

screw needs to rotate by (10mm ÷ 5 mm/rev)= 2 move distance per move command pulse.<br />

Revs<br />

For example:<br />

3. Command pulses required to cause one revolution:- 1. One Pulse command = Move distance of 1μm.<br />

= Encoder ppr × ( Internal multiplication factor). 2. If the Motion Table needs to move 10mm,<br />

= 2000 ppr x 4 = 8000 pulses.<br />

Then the required command pulses from a Host Controller<br />

4.So the Command pulses required to move 10mm (2 is<br />

revs):-<br />

= 10mm ÷ 1μm / Pulse.= 10000 Pulses.<br />

= 8000 pulses x 2 ( revs) = 16000 Pulses.<br />

Once the move distance per pulse and the Electronic<br />

gear ratio is known then the required number of pulse<br />

Number of command pulses for an specific move command can be calculated.<br />

distance can be calculated according to the formula<br />

below:<br />

= Number of Ball Screw Revs x (Encoder ppr x 4).<br />

5-37