Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

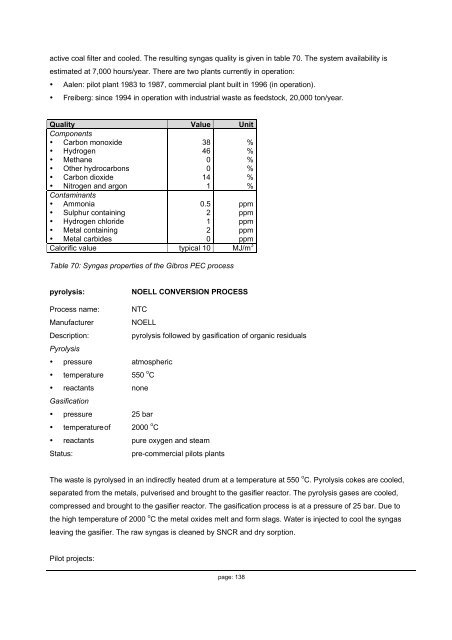

active coal filter and cooled. The resulting syn<strong>gas</strong> quality is given in table 70. The system availability isestimated at 7,000 hours/year. There are two plants currently in operation:• Aalen: pilot plant 1983 <strong>to</strong> 1987, commercial plant built in 1996 (in operation).• Freiberg: since 1994 in operation with industrial waste as feeds<strong>to</strong>ck, 20,000 <strong>to</strong>n/year.Quality Value UnitComponents• Carbon monoxide38 %• Hydrogen46 %• Methane0 %• O<strong>the</strong>r hydrocarbons0 %• Carbon dioxide14 %• Nitrogen and argon1 %Contaminants• Ammonia0.5 ppm• Sulphur containing2 ppm• Hydrogen chloride1 ppm• Metal containing2 ppm• Metal carbides0 ppmCalorific value typical 10 MJ/m 3Table 70: Syn<strong>gas</strong> properties of <strong>the</strong> Gibros PEC processpyrolysis:NOELL CONVERSION PROCESSProcess name: NTCManufacturerNOELLDescription:pyrolysis followed by <strong>gas</strong>ification of organic residualsPyrolysis• pressure atmospheric• temperature 550 o C• reactants noneGasification• pressure 25 bar• temperatureof 2000 o C• reactants pure oxygen and steamStatus:pre-commercial pilots plantsThe waste is pyrolysed in an indirectly heated drum at a temperature at 550 o C. Pyrolysis cokes are cooled,separated <strong>from</strong> <strong>the</strong> metals, pulverised and brought <strong>to</strong> <strong>the</strong> <strong>gas</strong>ifier reac<strong>to</strong>r. The pyrolysis <strong>gas</strong>es are cooled,compressed and brought <strong>to</strong> <strong>the</strong> <strong>gas</strong>ifier reac<strong>to</strong>r. The <strong>gas</strong>ification process is at a pressure of 25 bar. Due <strong>to</strong><strong>the</strong> high temperature of 2000 o C <strong>the</strong> metal oxides melt and form slags. Water is injected <strong>to</strong> cool <strong>the</strong> syn<strong>gas</strong>leaving <strong>the</strong> <strong>gas</strong>ifier. The raw syn<strong>gas</strong> is cleaned by SNCR and dry sorption.Pilot projects:page: 138