Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

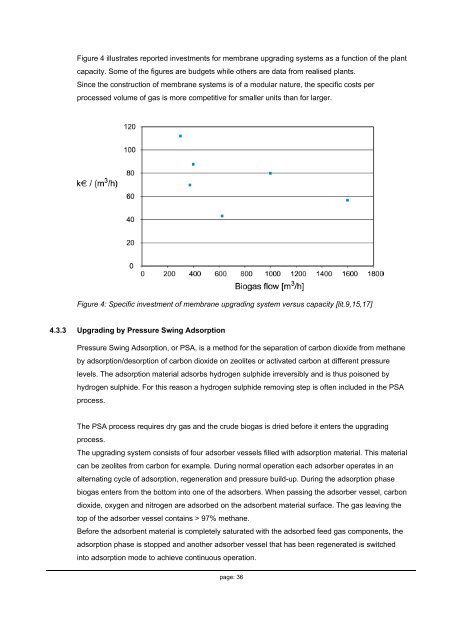

Figure 4 illustrates reported investments for membrane upgrading systems as a function of <strong>the</strong> plantcapacity. Some of <strong>the</strong> figures are budgets while o<strong>the</strong>rs are data <strong>from</strong> realised plants.Since <strong>the</strong> construction of membrane systems is of a modular nature, <strong>the</strong> specific costs perprocessed volume of <strong>gas</strong> is more competitive for smaller units than for larger.Figure 4: Specific investment of membrane upgrading system versus capacity [lit.9,15,17]4.3.3 Upgrading by Pressure Swing AdsorptionPressure Swing Adsorption, or PSA, is a method for <strong>the</strong> separation of carbon dioxide <strong>from</strong> methaneby adsorption/desorption of carbon dioxide on zeolites or activated carbon at different pressurelevels. The adsorption material adsorbs hydrogen sulphide irreversibly and is thus poisoned byhydrogen sulphide. For this reason a hydrogen sulphide removing step is often included in <strong>the</strong> PSAprocess.The PSA process requires dry <strong>gas</strong> and <strong>the</strong> crude bio<strong>gas</strong> is dried before it enters <strong>the</strong> upgradingprocess.The upgrading system consists of four adsorber vessels filled with adsorption material. This materialcan be zeolites <strong>from</strong> carbon for example. During normal operation each adsorber operates in analternating cycle of adsorption, regeneration and pressure build-up. During <strong>the</strong> adsorption phasebio<strong>gas</strong> enters <strong>from</strong> <strong>the</strong> bot<strong>to</strong>m in<strong>to</strong> one of <strong>the</strong> adsorbers. When passing <strong>the</strong> adsorber vessel, carbondioxide, oxygen and nitrogen are adsorbed on <strong>the</strong> adsorbent material surface. The <strong>gas</strong> leaving <strong>the</strong><strong>to</strong>p of <strong>the</strong> adsorber vessel contains > 97% methane.Before <strong>the</strong> adsorbent material is completely saturated with <strong>the</strong> adsorbed feed <strong>gas</strong> components, <strong>the</strong>adsorption phase is s<strong>to</strong>pped and ano<strong>the</strong>r adsorber vessel that has been regenerated is switchedin<strong>to</strong> adsorption mode <strong>to</strong> achieve continuous operation.page: 36