Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

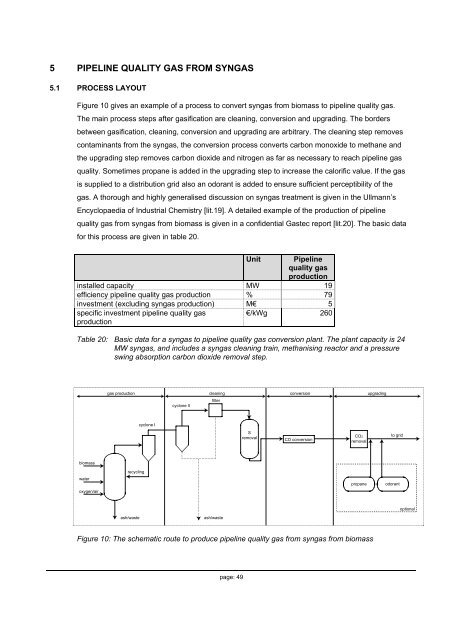

5 PIPELINE QUALITY GAS FROM SYNGAS5.1 PROCESS LAYOUTFigure 10 gives an example of a process <strong>to</strong> convert syn<strong>gas</strong> <strong>from</strong> <strong>biomass</strong> <strong>to</strong> pipeline quality <strong>gas</strong>.The main process steps after <strong>gas</strong>ification are cleaning, conversion and upgrading. The bordersbetween <strong>gas</strong>ification, cleaning, conversion and upgrading are arbitrary. The cleaning step removescontaminants <strong>from</strong> <strong>the</strong> syn<strong>gas</strong>, <strong>the</strong> conversion process converts carbon monoxide <strong>to</strong> methane and<strong>the</strong> upgrading step removes carbon dioxide and nitrogen as far as necessary <strong>to</strong> reach pipeline <strong>gas</strong>quality. Sometimes propane is added in <strong>the</strong> upgrading step <strong>to</strong> increase <strong>the</strong> calorific value. If <strong>the</strong> <strong>gas</strong>is supplied <strong>to</strong> a distribution <strong>grid</strong> also an odorant is added <strong>to</strong> ensure sufficient perceptibility of <strong>the</strong><strong>gas</strong>. A thorough and highly generalised discussion on syn<strong>gas</strong> treatment is given in <strong>the</strong> Ullmann’sEncyclopaedia of Industrial Chemistry [lit.19]. A detailed example of <strong>the</strong> production of pipelinequality <strong>gas</strong> <strong>from</strong> syn<strong>gas</strong> <strong>from</strong> <strong>biomass</strong> is given in a confidential Gastec report [lit.20]. The basic datafor this process are given in table 20.Unit Pipelinequality <strong>gas</strong>productioninstalled capacity MW 19efficiency pipeline quality <strong>gas</strong> production % 79investment (excluding syn<strong>gas</strong> production) M€ 5specific investment pipeline quality <strong>gas</strong>production€/kWg 260Table 20: Basic data for a syn<strong>gas</strong> <strong>to</strong> pipeline quality <strong>gas</strong> conversion plant. The plant capacity is 24MW syn<strong>gas</strong>, and includes a syn<strong>gas</strong> cleaning train, methanising reac<strong>to</strong>r and a pressureswing absorption carbon dioxide removal step.<strong>gas</strong> productioncleaningconversionupgradingcyclone IIfiltercyclone ISremovalCO conversionCO2removal<strong>to</strong> <strong>grid</strong><strong>biomass</strong>recyclingwaterpropaneodoran<strong>to</strong>xygen/airoptionalash/wasteash/wasteFigure 10: The schematic route <strong>to</strong> produce pipeline quality <strong>gas</strong> <strong>from</strong> syn<strong>gas</strong> <strong>from</strong> <strong>biomass</strong>page: 49