Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

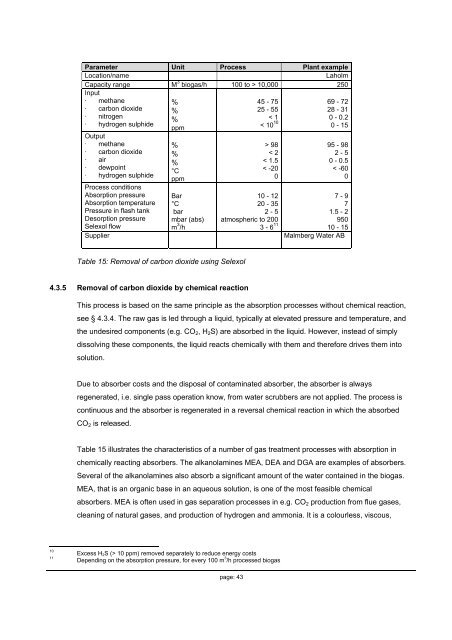

Parameter Unit Process Plant exampleLocation/nameLaholmCapacity range M 3 bio<strong>gas</strong>/h 100 <strong>to</strong> > 10,000 250Input· methane%45 - 7569 - 72· carbon dioxide %25 - 5528 - 31· nitrogen%< 10 - 0.2· hydrogen sulphideppm< 10 10 0 - 15Output· methane· carbon dioxide· air· dewpoint· hydrogen sulphideProcess conditionsAbsorption pressureAbsorption temperaturePressure in flash tankDesorption pressureSelexol flowSupplier%%%°CppmBar°Cbarmbar (abs)m 3 /h> 98< 2< 1.5< -20095 - 982 - 50 - 0.5< -60010 - 127 - 920 - 3572 - 51.5 - 2atmospheric <strong>to</strong> 2009503 - 6 11 10 - 15Malmberg Water ABTable 15: Removal of carbon dioxide using Selexol4.3.5 Removal of carbon dioxide by chemical reactionThis process is based on <strong>the</strong> same principle as <strong>the</strong> absorption processes without chemical reaction,see § 4.3.4. The raw <strong>gas</strong> is led through a liquid, typically at elevated pressure and temperature, and<strong>the</strong> undesired components (e.g. CO 2 , H 2 S) are absorbed in <strong>the</strong> liquid. However, instead of simplydissolving <strong>the</strong>se components, <strong>the</strong> liquid reacts chemically with <strong>the</strong>m and <strong>the</strong>refore drives <strong>the</strong>m in<strong>to</strong>solution.Due <strong>to</strong> absorber costs and <strong>the</strong> disposal of contaminated absorber, <strong>the</strong> absorber is alwaysregenerated, i.e. single pass operation know, <strong>from</strong> water scrubbers are not applied. The process iscontinuous and <strong>the</strong> absorber is regenerated in a reversal chemical reaction in which <strong>the</strong> absorbedCO 2 is released.Table 15 illustrates <strong>the</strong> characteristics of a number of <strong>gas</strong> treatment processes with absorption inchemically reacting absorbers. The alkanolamines MEA, DEA and DGA are examples of absorbers.Several of <strong>the</strong> alkanolamines also absorb a significant amount of <strong>the</strong> water contained in <strong>the</strong> bio<strong>gas</strong>.MEA, that is an organic base in an aqueous solution, is one of <strong>the</strong> most feasible chemicalabsorbers. MEA is often used in <strong>gas</strong> separation processes in e.g. CO 2 production <strong>from</strong> flue <strong>gas</strong>es,cleaning of natural <strong>gas</strong>es, and production of hydrogen and ammonia. It is a colourless, viscous,1011Excess H 2S (> 10 ppm) removed separately <strong>to</strong> reduce energy costsDepending on <strong>the</strong> absorption pressure, for every 100 m 3 /h processed bio<strong>gas</strong>page: 43