Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

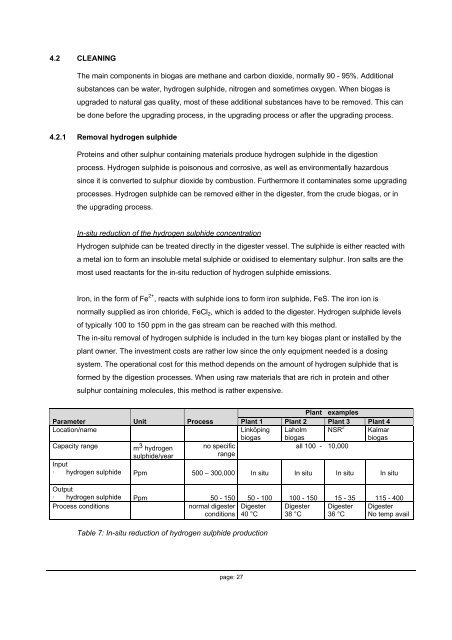

4.2 CLEANINGThe main components in bio<strong>gas</strong> are methane and carbon dioxide, normally 90 - 95%. Additionalsubstances can be water, hydrogen sulphide, nitrogen and sometimes oxygen. When bio<strong>gas</strong> isupgraded <strong>to</strong> natural <strong>gas</strong> quality, most of <strong>the</strong>se additional substances have <strong>to</strong> be removed. This canbe done before <strong>the</strong> upgrading process, in <strong>the</strong> upgrading process or after <strong>the</strong> upgrading process.4.2.1 Removal hydrogen sulphideProteins and o<strong>the</strong>r sulphur containing materials produce hydrogen sulphide in <strong>the</strong> digestionprocess. Hydrogen sulphide is poisonous and corrosive, as well as environmentally hazardoussince it is converted <strong>to</strong> sulphur dioxide by combustion. Fur<strong>the</strong>rmore it contaminates some upgradingprocesses. Hydrogen sulphide can be removed ei<strong>the</strong>r in <strong>the</strong> digester, <strong>from</strong> <strong>the</strong> crude bio<strong>gas</strong>, or in<strong>the</strong> upgrading process.In-situ reduction of <strong>the</strong> hydrogen sulphide concentrationHydrogen sulphide can be treated directly in <strong>the</strong> digester vessel. The sulphide is ei<strong>the</strong>r reacted witha metal ion <strong>to</strong> form an insoluble metal sulphide or oxidised <strong>to</strong> elementary sulphur. Iron salts are <strong>the</strong>most used reactants for <strong>the</strong> in-situ reduction of hydrogen sulphide emissions.Iron, in <strong>the</strong> form of Fe 2+ , reacts with sulphide ions <strong>to</strong> form iron sulphide, FeS. The iron ion isnormally supplied as iron chloride, FeCl 2 , which is added <strong>to</strong> <strong>the</strong> digester. Hydrogen sulphide levelsof typically 100 <strong>to</strong> 150 ppm in <strong>the</strong> <strong>gas</strong> stream can be reached with this method.The in-situ removal of hydrogen sulphide is included in <strong>the</strong> turn key bio<strong>gas</strong> plant or installed by <strong>the</strong>plant owner. The investment costs are ra<strong>the</strong>r low since <strong>the</strong> only equipment needed is a dosingsystem. The operational cost for this method depends on <strong>the</strong> amount of hydrogen sulphide that isformed by <strong>the</strong> digestion processes. When using raw materials that are rich in protein and o<strong>the</strong>rsulphur containing molecules, this method is ra<strong>the</strong>r expensive.Plant examplesParameter Unit Process Plant 1 Plant 2 Plant 3 Plant 4Location/nameLinköpingbio<strong>gas</strong>Laholmbio<strong>gas</strong>NSR 2 Kalmarbio<strong>gas</strong>Capacity rangem 3 hydrogen no specificall 100 - 10,000sulphide/yearrangeInput· hydrogen sulphide Ppm500 – 300,000 In situ In situ In situ In situOutput· hydrogen sulphide Ppm50 - 150 50 - 100 100 - 150 15 - 35 115 - 400Process conditionsnormal digesterconditionsDigester40 °CDigester38 °CDigester36 °CDigesterNo temp availTable 7: In-situ reduction of hydrogen sulphide productionpage: 27