Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

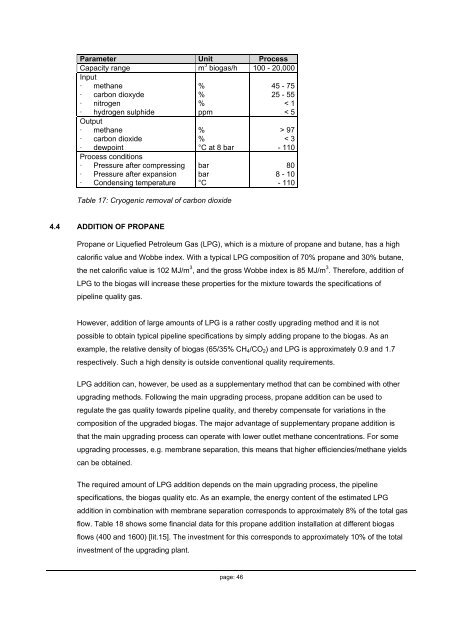

Parameter Unit ProcessCapacity range m 3 bio<strong>gas</strong>/h 100 - 20,000Input· methane· carbon dioxyde· nitrogen· hydrogen sulphideOutput· methane· carbon dioxide· dewpointProcess conditions· Pressure after compressing· Pressure after expansion· Condensing temperature%%%ppm%%°C at 8 barbarbar°CTable 17: Cryogenic removal of carbon dioxide45 - 7525 - 55< 1< 5> 97< 3- 110808 - 10- 1104.4 ADDITION OF PROPANEPropane or Liquefied Petroleum Gas (LPG), which is a mixture of propane and butane, has a highcalorific value and Wobbe index. With a typical LPG composition of 70% propane and 30% butane,<strong>the</strong> net calorific value is 102 MJ/m 3 , and <strong>the</strong> gross Wobbe index is 85 MJ/m 3 . Therefore, addition ofLPG <strong>to</strong> <strong>the</strong> bio<strong>gas</strong> will increase <strong>the</strong>se properties for <strong>the</strong> mixture <strong>to</strong>wards <strong>the</strong> specifications ofpipeline quality <strong>gas</strong>.However, addition of large amounts of LPG is a ra<strong>the</strong>r costly upgrading method and it is notpossible <strong>to</strong> obtain typical pipeline specifications by simply adding propane <strong>to</strong> <strong>the</strong> bio<strong>gas</strong>. As anexample, <strong>the</strong> relative density of bio<strong>gas</strong> (65/35% CH 4 /CO 2 ) and LPG is approximately 0.9 and 1.7respectively. Such a high density is outside conventional quality requirements.LPG addition can, however, be used as a supplementary method that can be combined with o<strong>the</strong>rupgrading methods. Following <strong>the</strong> main upgrading process, propane addition can be used <strong>to</strong>regulate <strong>the</strong> <strong>gas</strong> quality <strong>to</strong>wards pipeline quality, and <strong>the</strong>reby compensate for variations in <strong>the</strong>composition of <strong>the</strong> upgraded bio<strong>gas</strong>. The major advantage of supplementary propane addition isthat <strong>the</strong> main upgrading process can operate with lower outlet methane concentrations. For someupgrading processes, e.g. membrane separation, this means that higher efficiencies/methane yieldscan be obtained.The required amount of LPG addition depends on <strong>the</strong> main upgrading process, <strong>the</strong> pipelinespecifications, <strong>the</strong> bio<strong>gas</strong> quality etc. As an example, <strong>the</strong> energy content of <strong>the</strong> estimated LPGaddition in combination with membrane separation corresponds <strong>to</strong> approximately 8% of <strong>the</strong> <strong>to</strong>tal <strong>gas</strong>flow. Table 18 shows some financial data for this propane addition installation at different bio<strong>gas</strong>flows (400 and 1600) [lit.15]. The investment for this corresponds <strong>to</strong> approximately 10% of <strong>the</strong> <strong>to</strong>talinvestment of <strong>the</strong> upgrading plant.page: 46