Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

Adding gas from biomass to the gas grid - SGC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

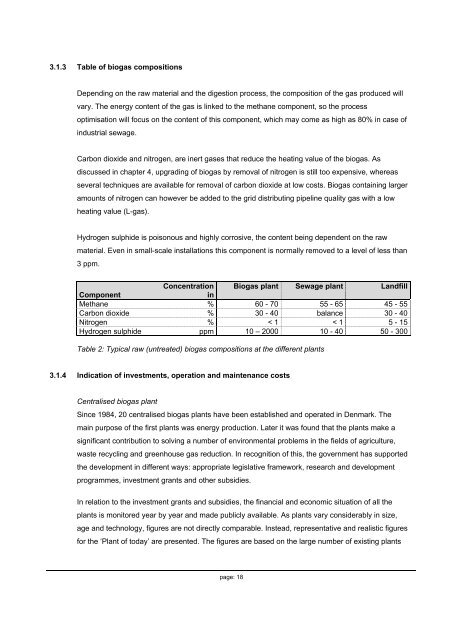

3.1.3 Table of bio<strong>gas</strong> compositionsDepending on <strong>the</strong> raw material and <strong>the</strong> digestion process, <strong>the</strong> composition of <strong>the</strong> <strong>gas</strong> produced willvary. The energy content of <strong>the</strong> <strong>gas</strong> is linked <strong>to</strong> <strong>the</strong> methane component, so <strong>the</strong> processoptimisation will focus on <strong>the</strong> content of this component, which may come as high as 80% in case ofindustrial sewage.Carbon dioxide and nitrogen, are inert <strong>gas</strong>es that reduce <strong>the</strong> heating value of <strong>the</strong> bio<strong>gas</strong>. Asdiscussed in chapter 4, upgrading of bio<strong>gas</strong> by removal of nitrogen is still <strong>to</strong>o expensive, whereasseveral techniques are available for removal of carbon dioxide at low costs. Bio<strong>gas</strong> containing largeramounts of nitrogen can however be added <strong>to</strong> <strong>the</strong> <strong>grid</strong> distributing pipeline quality <strong>gas</strong> with a lowheating value (L-<strong>gas</strong>).Hydrogen sulphide is poisonous and highly corrosive, <strong>the</strong> content being dependent on <strong>the</strong> rawmaterial. Even in small-scale installations this component is normally removed <strong>to</strong> a level of less than3 ppm.Concentration Bio<strong>gas</strong> plant Sewage plant LandfillComponentinMethane % 60 - 70 55 - 65 45 - 55Carbon dioxide % 30 - 40 balance 30 - 40Nitrogen % < 1 < 1 5 - 15Hydrogen sulphide ppm10 – 2000 10 - 40 50 - 300Table 2: Typical raw (untreated) bio<strong>gas</strong> compositions at <strong>the</strong> different plants3.1.4 Indication of investments, operation and maintenance costsCentralised bio<strong>gas</strong> plantSince 1984, 20 centralised bio<strong>gas</strong> plants have been established and operated in Denmark. Themain purpose of <strong>the</strong> first plants was energy production. Later it was found that <strong>the</strong> plants make asignificant contribution <strong>to</strong> solving a number of environmental problems in <strong>the</strong> fields of agriculture,waste recycling and greenhouse <strong>gas</strong> reduction. In recognition of this, <strong>the</strong> government has supported<strong>the</strong> development in different ways: appropriate legislative framework, research and developmentprogrammes, investment grants and o<strong>the</strong>r subsidies.In relation <strong>to</strong> <strong>the</strong> investment grants and subsidies, <strong>the</strong> financial and economic situation of all <strong>the</strong>plants is moni<strong>to</strong>red year by year and made publicly available. As plants vary considerably in size,age and technology, figures are not directly comparable. Instead, representative and realistic figuresfor <strong>the</strong> ‘Plant of <strong>to</strong>day’ are presented. The figures are based on <strong>the</strong> large number of existing plantspage: 18