- Page 1 and 2:

®Established 1981Advanced Test Equ

- Page 3 and 4:

WARRANTYKeithley Instruments, Inc.

- Page 5 and 6:

Manual Print HistoryThe print histo

- Page 7 and 8:

If you are using a test fixture, ke

- Page 9 and 10:

Table of Contents1 General Informat

- Page 11 and 12:

4.10.3 Scanning examples ..........

- Page 13:

5.13.4 :FCHannels ................

- Page 16 and 17:

List of Illustrations2 Card Install

- Page 18 and 19:

6 Theory of OperationFigure 6-1 Mod

- Page 20 and 21:

8 MaintenanceTable 8-1Table 8-2Tabl

- Page 22 and 23:

General Informationthorized repair

- Page 24 and 25:

Card InstallationNOTEIf using the s

- Page 26 and 27:

3Getting Started3.1 IntroductionThi

- Page 28 and 29:

Getting StartedWARNING: INTERCONNEC

- Page 30 and 31:

Getting StartedSLOT 112ROW34COLUMN

- Page 32 and 33:

Getting Started3.6 Overview of scan

- Page 34 and 35:

Getting Started3.7.2 Close and open

- Page 36 and 37:

Getting Started2. If the scan list

- Page 38 and 39:

Getting Started3.8 Switching card c

- Page 40 and 41:

Getting Started3.9.2 Close and Open

- Page 42 and 43:

Getting StartedSCPI (Standard Comma

- Page 44 and 45:

Getting Started3.10.5 Abbreviated s

- Page 46 and 47:

Getting Started20 OUTPUT 707; “:s

- Page 48 and 49:

4Front Panel Operation4.1 Introduct

- Page 50 and 51:

Front Panel OperationAnnunciatorsTa

- Page 52 and 53:

Front Panel Operation3COLUMNSLOT 1

- Page 54 and 55:

Front Panel OperationNot all Model

- Page 56 and 57: Front Panel Operationthe VFD which

- Page 58 and 59: Front Panel OperationFront panel ke

- Page 60 and 61: Front Panel OperationSlot 111 2 3 4

- Page 62 and 63: Front Panel Operation4.8 Channel li

- Page 64 and 65: Front Panel OperationStep 3. Enter

- Page 66 and 67: Front Panel Operationd. Click the I

- Page 68 and 69: Front Panel OperationIdleOPEN ALLId

- Page 70 and 71: Front Panel OperationChannel layerN

- Page 72 and 73: Front Panel Operationsatisfy a chan

- Page 74 and 75: Front Panel OperationExample 3:ARM

- Page 76 and 77: Front Panel Operation6. To store th

- Page 78 and 79: Front Panel Operation8. The INFO ke

- Page 80 and 81: Front Panel Operation4.12.2 GPIBThe

- Page 82 and 83: Front Panel OperationPerform the fo

- Page 84 and 85: Front Panel OperationPlace the curs

- Page 86 and 87: Front Panel OperationThe message in

- Page 88 and 89: Front Panel Operation4.14 Scan conf

- Page 90 and 91: Front Panel OperationTable 4-7 (con

- Page 92 and 93: Front Panel Operationline. Perform

- Page 94 and 95: Front Panel Operation2. To retain t

- Page 96 and 97: Front Panel OperationPerform the fo

- Page 98 and 99: Front Panel Operation4.14.4 Channel

- Page 100 and 101: Front Panel Operation3. Interlocked

- Page 102 and 103: Front Panel OperationPin 7 - Digita

- Page 104 and 105: Front Panel OperationCHANNELREADY4.

- Page 108 and 109: Front Panel OperationDUT#11OUTPUTDU

- Page 110 and 111: Front Panel OperationBypass7002Pres

- Page 112 and 113: Front Panel OperationDUT#11OUTPUTHI

- Page 114 and 115: Front Panel Operation7002Press STEP

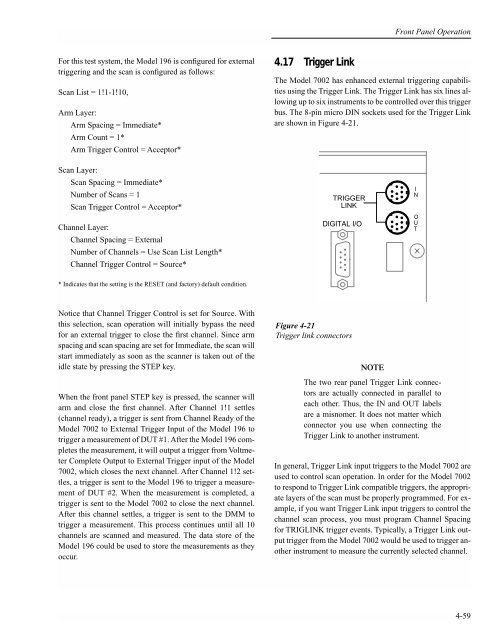

- Page 116 and 117: Front Panel OperationINOUTTriggerLi

- Page 118 and 119: Front Panel Operationmeter to measu

- Page 120 and 121: 5IEEE-488 Reference5.1 Introduction

- Page 122 and 123: IEEE-488 ReferenceIEEE-488Table 5-1

- Page 124 and 125: IEEE-488 ReferenceNOTEController pr

- Page 126 and 127: IEEE-488 ReferenceTriggerTransition

- Page 128 and 129: IEEE-488 ReferenceStandard Event St

- Page 130 and 131: IEEE-488 ReferenceThe filter can be

- Page 132 and 133: IEEE-488 ReferenceArm Condition Reg

- Page 134 and 135: IEEE-488 ReferenceAlwaysZeroLay2Lay

- Page 136 and 137: IEEE-488 ReferenceAlwaysZeroSeq1(B1

- Page 138 and 139: IEEE-488 Reference5.6.6 Questionabl

- Page 140 and 141: IEEE-488 ReferenceReading this regi

- Page 142 and 143: IEEE-488 ReferenceB6 is called the

- Page 144: IEEE-488 Reference:ABORt*RST:SYST:P

- Page 147 and 148: IEEE-488 ReferenceWith the Manual c

- Page 149 and 150: IEEE-488 Reference5.8.2 IFC (interf

- Page 151 and 152: IEEE-488 Reference5-32

- Page 153: IEEE-488 Reference• While ignorin

- Page 156 and 157:

IEEE-488 Referenceas command paths.

- Page 158 and 159:

IEEE-488 ReferenceResponse messages

- Page 160 and 161:

IEEE-488 Reference5.10 Common comma

- Page 162 and 163:

IEEE-488 Reference5.10.1 *CLS ⎯ c

- Page 164 and 165:

IEEE-488 Referencewhere; CME (bit B

- Page 166 and 167:

IEEE-488 Reference5.10.4 *ESR? ⎯

- Page 168 and 169:

IEEE-488 Reference5.10.5 *IDN? ⎯

- Page 170 and 171:

IEEE-488 ReferenceNOTESee *OPC?, *T

- Page 172 and 173:

IEEE-488 ReferenceAfter *OPC? is ex

- Page 174 and 175:

IEEE-488 Reference5.10.9 *RCL ⎯ r

- Page 176 and 177:

IEEE-488 ReferenceTable 5-5Default

- Page 178 and 179:

IEEE-488 Reference5.10.12 *SRE ⎯

- Page 180 and 181:

IEEE-488 Reference5.10.13 *SRE? ⎯

- Page 182 and 183:

IEEE-488 ReferenceBit 5, Event Summ

- Page 184 and 185:

IEEE-488 Reference5.10.16 *TST? ⎯

- Page 186 and 187:

IEEE-488 ReferenceLine 70 Wait unti

- Page 188 and 189:

IEEE-488 ReferenceSCPI command subs

- Page 190 and 191:

IEEE-488 Reference5.11 :DISPlay sub

- Page 192 and 193:

:DISPlay subsystemIEEE-488 Referenc

- Page 194 and 195:

:DISPlay subsystemIEEE-488 Referenc

- Page 196 and 197:

IEEE-488 Reference5.12 :OUTPut subs

- Page 198 and 199:

IEEE-488 Reference5.13 [:ROUTe] sub

- Page 200 and 201:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 202 and 203:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 204 and 205:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 206 and 207:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 208 and 209:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 210 and 211:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 212 and 213:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 214 and 215:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 216 and 217:

[:ROUTe] subsystemIEEE-488 Referenc

- Page 218 and 219:

IEEE-488 Reference5.14 Sense subsys

- Page 220 and 221:

IEEE-488 Reference5.15 :SOURce subs

- Page 222 and 223:

IEEE-488 Reference5.16 :STATus subs

- Page 224 and 225:

:STATus SubsystemIEEE-488 Reference

- Page 226 and 227:

:STATus SubsystemIEEE-488 Reference

- Page 228 and 229:

:STATus SubsystemIEEE-488 Reference

- Page 230 and 231:

:STATus SubsystemIEEE-488 Reference

- Page 232 and 233:

:STATus SubsystemIEEE-488 Reference

- Page 234 and 235:

:STATus SubsystemIEEE-488 Reference

- Page 236 and 237:

:STATus SubsystemIEEE-488 Reference

- Page 238 and 239:

:STATus SubsystemIEEE-488 Reference

- Page 240 and 241:

:STATus SubsystemIEEE-488 Reference

- Page 242 and 243:

:STATus SubsystemIEEE-488 Reference

- Page 244 and 245:

:STATus SubsystemIEEE-488 Reference

- Page 246 and 247:

IEEE-488 Reference5.17 :SYSTem subs

- Page 248 and 249:

:SYSTem SubsystemIEEE-488 Reference

- Page 250 and 251:

IEEE-488 Reference5.18 Trigger subs

- Page 252 and 253:

Trigger subsystemIEEE-488 Reference

- Page 254 and 255:

Trigger subsystemIEEE-488 Reference

- Page 256 and 257:

Trigger subsystemIEEE-488 Reference

- Page 258 and 259:

Trigger subsystemIEEE-488 Reference

- Page 260 and 261:

Trigger subsystemIEEE-488 Reference

- Page 262 and 263:

Trigger subsystemIEEE-488 Reference

- Page 264 and 265:

Trigger subsystemIEEE-488 Reference

- Page 266 and 267:

6Theory of Operation6.1 Introductio

- Page 268 and 269:

Theory of Operation6.3 Control func

- Page 270 and 271:

Theory of Operation6.4 Relay contro

- Page 272 and 273:

Theory of OperationID data is conta

- Page 274 and 275:

Theory of OperationFromDigitalBoard

- Page 276 and 277:

Theory of Operationµ DINConnectorT

- Page 278 and 279:

MaintenanceNOTEThe digital and disp

- Page 280 and 281:

MaintenanceFuse replacement procedu

- Page 282 and 283:

Maintenance7.6 Instrument disassemb

- Page 284 and 285:

Maintenance7.6.5 Power supplies rem

- Page 286 and 287:

Maintenance8. Press “1”, “1

- Page 288 and 289:

MaintenanceEDIT ERR REM TALK LSTN S

- Page 290 and 291:

MaintenanceTo review the error, pre

- Page 292 and 293:

MaintenanceTrigger 8 (STI8) is set

- Page 294 and 295:

MaintenanceDETAIL AREF:GRN/YELWIRE#

- Page 296 and 297:

MaintenanceBOARDS MUST BE HANDLED W

- Page 298 and 299:

MaintenanceSTEP 1FA-151-1, FASTENER

- Page 300 and 301:

MaintenanceDETAIL ACC-47, CABLEDIG

- Page 302 and 303:

Maintenance8#4-40x1/4"PFH(4 REQ'D)(

- Page 304 and 305:

Replaceable Parts

- Page 306 and 307:

Replaceable Parts

- Page 311 and 312:

Replaceable PartsTable 8-2Digital b

- Page 313 and 314:

Artisan Scientific - Quality Instru

- Page 315:

(+5V)**(+5V)**** ****** **********

- Page 318 and 319:

Replaceable PartsTable 8-3VFD displ

- Page 322 and 323:

Replaceable PartsTable 8-4Backplane

- Page 324:

Artisan Scientific - Quality Instru

- Page 327 and 328:

Replaceable Parts

- Page 331 and 332:

Replaceable PartsTable 8-6Miscellan

- Page 333 and 334:

Interface Function CodesTable A-1Mo

- Page 335 and 336:

Controller ProgramsIBM PC/XT/AT wit

- Page 337 and 338:

Controller Programs10 DEF SEG=&HC40

- Page 339 and 340:

Controller ProgramsHewlett-Packard

- Page 341 and 342:

Controller ProgramsBUS.INIT\ Initia

- Page 343 and 344:

CASCII Character Codesand IEEE-488

- Page 345 and 346:

ASCII Character Codes and IEEE-488M

- Page 347 and 348:

IEEE-488 Bus Overviewtype of instru

- Page 349 and 350:

IEEE-488 Bus Overviewdevice will re

- Page 351 and 352:

IEEE-488 Bus OverviewLAG (Listen Ad

- Page 353 and 354:

IEEE-488 Bus OverviewTable D-2Hexad

- Page 355 and 356:

EIEEE-488 Conformance InformationIn

- Page 357 and 358:

FSCPI Conformance InformationIntrod

- Page 359 and 360:

SCPI Conformance InformationTable F

- Page 361 and 362:

SCPI Conformance InformationTable F

- Page 363 and 364:

SCPI Conformance InformationTable F

- Page 365 and 366:

IEEE-488.2 Common CommandsMnemonic

- Page 367 and 368:

SCPI Command SubsystemTable H-1DISP

- Page 369 and 370:

SCPI Command SubsystemTable H-4SENS

- Page 371 and 372:

SCPI Command SubsystemTable H-6 (co

- Page 373 and 374:

SCPI Command SubsystemTable H-8 (co

- Page 375 and 376:

QuickBasic and QuickC ProgramsMicro

- Page 377 and 378:

QuickBasic and QuickC ProgramsMicro

- Page 379 and 380:

Index:ABORt 5-134:BBMake 5-88:CLOS

- Page 381 and 382:

Scanning channels 4-20Scanning exam

- Page 383:

Specifications are subject to chang