FLK Gas Sampling System - MPIP - Free

FLK Gas Sampling System - MPIP - Free

FLK Gas Sampling System - MPIP - Free

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SQ256 Retraction Device<br />

The probe can be traversed using a compressed air motor. Insertion and retraction are possible by interchanging<br />

the compressed air feed on the motor.<br />

The retraction device must be aligned such that the probe is in the correct position in the kiln or cyclone in the<br />

inserted state.<br />

The centre of the probe must be positioned about 5-10mm above the centre of the probe inlet. The height can be<br />

adjusted by washers on the probe or by shims on the support.<br />

Then weld the connecting piece with the outer casing of the kiln or cyclone. Seal the pipe inside the kiln or cyclone<br />

with special cement. Permanently fix the traverse rail at the front and back.<br />

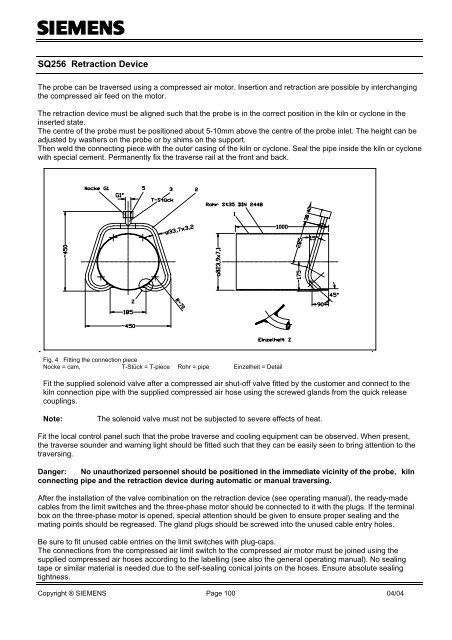

Fig. 4 Fitting the connection piece<br />

Nocke = cam, T-Stück = T-piece Rohr = pipe Einzelheit = Detail<br />

Fit the supplied solenoid valve after a compressed air shut-off valve fitted by the customer and connect to the<br />

kiln connection pipe with the supplied compressed air hose using the screwed glands from the quick release<br />

couplings.<br />

Note:<br />

The solenoid valve must not be subjected to severe effects of heat.<br />

Fit the local control panel such that the probe traverse and cooling equipment can be observed. When present,<br />

the traverse sounder and warning light should be fitted such that they can be easily seen to bring attention to the<br />

traversing.<br />

Danger: No unauthorized personnel should be positioned in the immediate vicinity of the probe, kiln<br />

connecting pipe and the retraction device during automatic or manual traversing.<br />

After the installation of the valve combination on the retraction device (see operating manual), the ready-made<br />

cables from the limit switches and the three-phase motor should be connected to it with the plugs. If the terminal<br />

box on the three-phase motor is opened, special attention should be given to ensure proper sealing and the<br />

mating points should be regreased. The gland plugs should be screwed into the unused cable entry holes.<br />

Be sure to fit unused cable entries on the limit switches with plug-caps.<br />

The connections from the compressed air limit switch to the compressed air motor must be joined using the<br />

supplied compressed air hoses according to the labelling (see also the general operating manual). No sealing<br />

tape or similar material is needed due to the self-sealing conical joints on the hoses. Ensure absolute sealing<br />

tightness.<br />

Copyright ® SIEMENS Page 100 04/04

![[ ]](https://img.yumpu.com/53283450/1/184x260/-.jpg?quality=85)