FLK Gas Sampling System - MPIP - Free

FLK Gas Sampling System - MPIP - Free

FLK Gas Sampling System - MPIP - Free

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SQ250 <strong>FLK</strong> <strong>Gas</strong> <strong>Sampling</strong> <strong>System</strong><br />

It should be ensured that the connection between the probe and the connection point with the probe inserted always slopes<br />

down ( no collection of condensate in "water pockets"). Also further on, the pipe must be laid as already stated either rising<br />

or falling towards the analysis device.<br />

With special analyses, such as for example SO 2 , a heated measuring gas line regulated thermostatically to approx. >150°C<br />

must be used. This line is then directly connected to the measuring gas output of the heated filter. It must be fixed with<br />

mounting clamps at the connection point and routed further up to the analysis equipment.<br />

Secure all hose connections with hose clamps (e.g. Norma or UNEX K010 Hose Connectors).<br />

To prevent mechanical damage, the measuring line can be laid in steel conduit or plastic ducting. It should be ensured that<br />

edges are rounded off or fitted with plastic edging.<br />

At points where there is a risk of frost the measuring line should be laid in an insulated plastic duct running in parallel with a<br />

heater pipe. The heater must be designed such that the measuring gas line (e.g. plastic pipe) is not damaged, but freezing is<br />

not possible.<br />

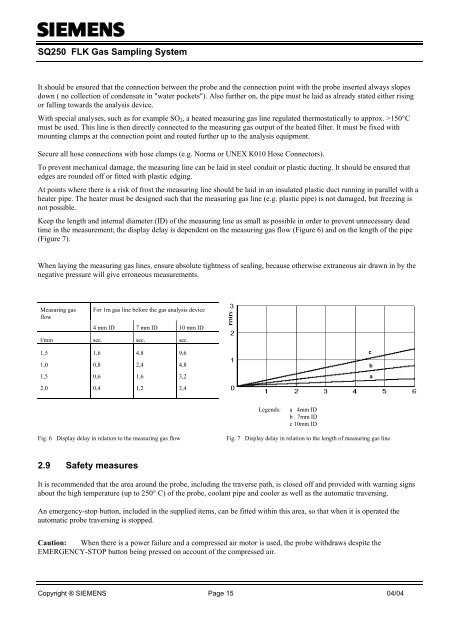

Keep the length and internal diameter (ID) of the measuring line as small as possible in order to prevent unnecessary dead<br />

time in the measurement; the display delay is dependent on the measuring gas flow (Figure 6) and on the length of the pipe<br />

(Figure 7).<br />

When laying the measuring gas lines, ensure absolute tightness of sealing, because otherwise extraneous air drawn in by the<br />

negative pressure will give erroneous measurements.<br />

Measuring gas<br />

flow<br />

For 1m gas line before the gas analysis device<br />

4 mm ID 7 mm ID 10 mm ID<br />

l/min sec. sec. sec.<br />

1,5<br />

1,6<br />

4,8<br />

9,6<br />

c<br />

1,0<br />

0,8<br />

2,4<br />

4,8<br />

b<br />

1,5<br />

0,6<br />

1,6<br />

3,2<br />

a<br />

2,0<br />

0,4<br />

1,2<br />

2,4<br />

Legends:<br />

a 4mm ID<br />

b 7mm ID<br />

c 10mm ID<br />

Fig. 6 Display delay in relation to the measuring gas flow<br />

Fig. 7 Display delay in relation to the length of measuring gas line<br />

2.9 Safety measures<br />

It is recommended that the area around the probe, including the traverse path, is closed off and provided with warning signs<br />

about the high temperature (up to 250° C) of the probe, coolant pipe and cooler as well as the automatic traversing.<br />

An emergency-stop button, included in the supplied items, can be fitted within this area, so that when it is operated the<br />

automatic probe traversing is stopped.<br />

Caution: When there is a power failure and a compressed air motor is used, the probe withdraws despite the<br />

EMERGENCY-STOP button being pressed on account of the compressed air.<br />

Copyright ® SIEMENS Page 15 04/04

![[ ]](https://img.yumpu.com/53283450/1/184x260/-.jpg?quality=85)