Carriage, Handling and Storage of Dangerous Goods along

Carriage, Handling and Storage of Dangerous Goods along

Carriage, Handling and Storage of Dangerous Goods along

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

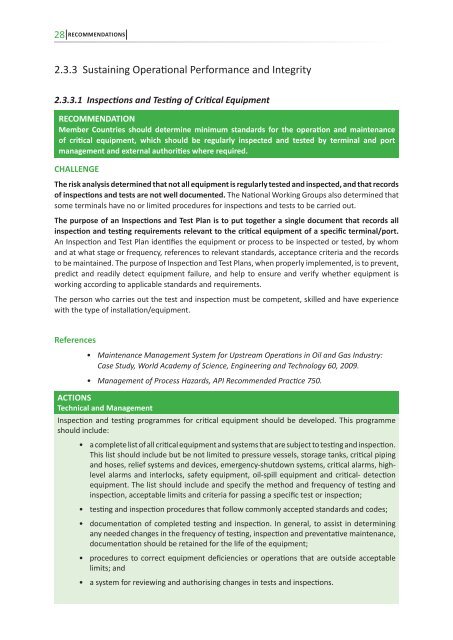

28 RECOMMENDATIONS<br />

2.3.3 Sustaining Operational Performance <strong>and</strong> Integrity<br />

2.3.3.1 Inspections <strong>and</strong> Testing <strong>of</strong> Critical Equipment<br />

RECOMMENDATION<br />

Member Countries should determine minimum st<strong>and</strong>ards for the operation <strong>and</strong> maintenance<br />

<strong>of</strong> critical equipment, which should be regularly inspected <strong>and</strong> tested by terminal <strong>and</strong> port<br />

management <strong>and</strong> external authorities where required.<br />

CHALLENGE<br />

The risk analysis determined that not all equipment is regularly tested <strong>and</strong> inspected, <strong>and</strong> that records<br />

<strong>of</strong> inspections <strong>and</strong> tests are not well documented. The National Working Groups also determined that<br />

some terminals have no or limited procedures for inspections <strong>and</strong> tests to be carried out.<br />

The purpose <strong>of</strong> an Inspections <strong>and</strong> Test Plan is to put together a single document that records all<br />

inspection <strong>and</strong> testing requirements relevant to the critical equipment <strong>of</strong> a specific terminal/port.<br />

An Inspection <strong>and</strong> Test Plan identifies the equipment or process to be inspected or tested, by whom<br />

<strong>and</strong> at what stage or frequency, references to relevant st<strong>and</strong>ards, acceptance criteria <strong>and</strong> the records<br />

to be maintained. The purpose <strong>of</strong> Inspection <strong>and</strong> Test Plans, when properly implemented, is to prevent,<br />

predict <strong>and</strong> readily detect equipment failure, <strong>and</strong> help to ensure <strong>and</strong> verify whether equipment is<br />

working according to applicable st<strong>and</strong>ards <strong>and</strong> requirements.<br />

The person who carries out the test <strong>and</strong> inspection must be competent, skilled <strong>and</strong> have experience<br />

with the type <strong>of</strong> installation/equipment.<br />

References<br />

• Maintenance Management System for Upstream Operations in Oil <strong>and</strong> Gas Industry:<br />

Case Study, World Academy <strong>of</strong> Science, Engineering <strong>and</strong> Technology 60, 2009.<br />

• Management <strong>of</strong> Process Hazards, API Recommended Practice 750.<br />

ACTIONS<br />

Technical <strong>and</strong> Management<br />

Inspection <strong>and</strong> testing programmes for critical equipment should be developed. This programme<br />

should include:<br />

• a complete list <strong>of</strong> all critical equipment <strong>and</strong> systems that are subject to testing <strong>and</strong> inspection.<br />

This list should include but be not limited to pressure vessels, storage tanks, critical piping<br />

<strong>and</strong> hoses, relief systems <strong>and</strong> devices, emergency-shutdown systems, critical alarms, highlevel<br />

alarms <strong>and</strong> interlocks, safety equipment, oil-spill equipment <strong>and</strong> critical- detection<br />

equipment. The list should include <strong>and</strong> specify the method <strong>and</strong> frequency <strong>of</strong> testing <strong>and</strong><br />

inspection, acceptable limits <strong>and</strong> criteria for passing a specific test or inspection;<br />

• testing <strong>and</strong> inspection procedures that follow commonly accepted st<strong>and</strong>ards <strong>and</strong> codes;<br />

• documentation <strong>of</strong> completed testing <strong>and</strong> inspection. In general, to assist in determining<br />

any needed changes in the frequency <strong>of</strong> testing, inspection <strong>and</strong> preventative maintenance,<br />

documentation should be retained for the life <strong>of</strong> the equipment;<br />

• procedures to correct equipment deficiencies or operations that are outside acceptable<br />

limits; <strong>and</strong><br />

• a system for reviewing <strong>and</strong> authorising changes in tests <strong>and</strong> inspections.