buradan - Yangın

buradan - Yangın

buradan - Yangın

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

So apart from the impact on our lives, why are fires in warehouse<br />

so different to fire in other buildings?<br />

Here we have the fire triangle which I’m sure we are all familiar<br />

with. It highlights that in order to start and maintain a fire we need<br />

Oxygen, fuel and heat. Remove one of these and the triangle<br />

collapses and the fire will be extinguished. It is on this principle<br />

that fire suppression systems are based. In the case of sprinklers<br />

systems they work by cooling the fire with water droplets and by<br />

reducing the available fuel by pre-wetting the goods stored.<br />

Figure 3. Potential risk at side effect increase<br />

What we sometimes forget is that if we increase one or more of the<br />

three elements then the fire size will increase. If you have more<br />

heat, add more fuel or if you make more oxygen available then you<br />

will have a bigger fire.<br />

Warehouses by their very nature have the potential to significantly<br />

increase all three sides of the fire triangle, creating bigger fires than<br />

you would expect in say an office or shopping centre. It is against<br />

this unique challenge that sprinklers have proven themselves<br />

robust enough to tackle these difficult fires and yet adaptable so<br />

that they can cope with the ever changing demands of modern<br />

day logistics.<br />

Figure 4. Effect of fuel side on warehouse fires<br />

The amount of fuel available to a fire will certainly influence its size<br />

and no-one can deny that in today’s warehousing we have high<br />

concentrations of flammable materials.<br />

We only have to walk into any DIY store to see mixtures of<br />

flammable liquids stored next to aerosols and wooden furniture, all<br />

to great heights and with little space between the racks.<br />

In commercial distribution centres the situation is further worsened<br />

as more goods of more variety are stored. As land becomes harder<br />

or more expensive to obtain the result is that we store higher and<br />

higher – 20meters or more is not unheard of – further concentrating<br />

BİLDİRİLER KİTABI TÜYAK<br />

PROCEEDINGS BOOK 2009<br />

the goods. As fire travels vertically very quickly, this can have a<br />

dramatic impact on the size of fire.<br />

Packaging nowadays is almost entirely made of flammable<br />

materials, from expanded polystyrene around electrical goods<br />

to cardboard sleeves around food we add a huge amount of<br />

flammable materials to what we store – making the situation even<br />

worse. Even the pallets alone used in warehouses constitute a<br />

severe fire risk and unused pallets should ideally be stored outside<br />

of the building. So even if what you store is a relatively low fire risk,<br />

the packaging alone may create a major fire risk.<br />

Clearly if you compare this to other risks such as hotels,<br />

supermarkets or office developments then the fire loading – or<br />

available material to burn – is much higher.<br />

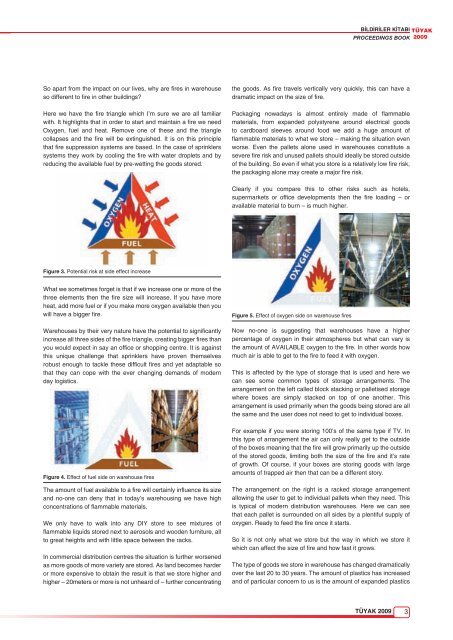

Figure 5. Effect of oxygen side on warehouse fires<br />

Now no-one is suggesting that warehouses have a higher<br />

percentage of oxygen in their atmospheres but what can vary is<br />

the amount of AVAILABLE oxygen to the fire. In other words how<br />

much air is able to get to the fire to feed it with oxygen.<br />

This is affected by the type of storage that is used and here we<br />

can see some common types of storage arrangements. The<br />

arrangement on the left called block stacking or palletised storage<br />

where boxes are simply stacked on top of one another. This<br />

arrangement is used primarily when the goods being stored are all<br />

the same and the user does not need to get to individual boxes.<br />

For example if you were storing 100’s of the same type if TV. In<br />

this type of arrangement the air can only really get to the outside<br />

of the boxes meaning that the fire will grow primarily up the outside<br />

of the stored goods, limiting both the size of the fire and it’s rate<br />

of growth. Of course, if your boxes are storing goods with large<br />

amounts of trapped air then that can be a different story.<br />

The arrangement on the right is a racked storage arrangement<br />

allowing the user to get to individual pallets when they need. This<br />

is typical of modern distribution warehouses. Here we can see<br />

that each pallet is surrounded on all sides by a plentiful supply of<br />

oxygen. Ready to feed the fire once it starts.<br />

So it is not only what we store but the way in which we store it<br />

which can affect the size of fire and how fast it grows.<br />

The type of goods we store in warehouse has changed dramatically<br />

over the last 20 to 30 years. The amount of plastics has increased<br />

and of particular concern to us is the amount of expanded plastics<br />

TÜYAK 2009<br />

3