London Wider Waste Strategy - London - Greater London Authority

London Wider Waste Strategy - London - Greater London Authority

London Wider Waste Strategy - London - Greater London Authority

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

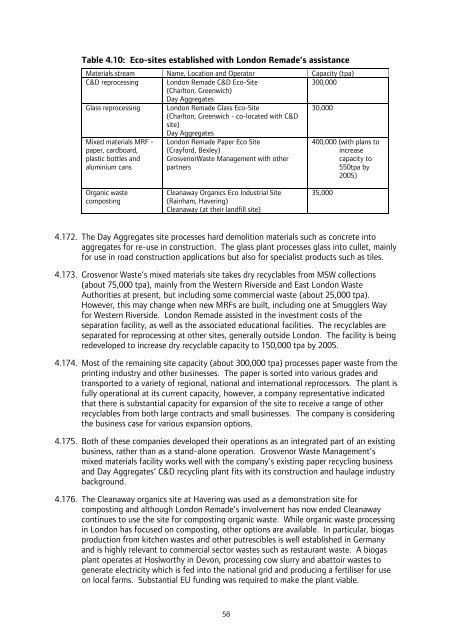

Table 4.10: Eco-sites established with <strong>London</strong> Remade’s assistance<br />

Materials stream Name, Location and Operator Capacity (tpa)<br />

C&D reprocessing <strong>London</strong> Remade C&D Eco-Site<br />

(Charlton, Greenwich)<br />

Day Aggregates<br />

300,000<br />

Glass reprocessing <strong>London</strong> Remade Glass Eco-Site<br />

(Charlton, Greenwich - co-located with C&D<br />

site)<br />

Day Aggregates<br />

30,000<br />

Mixed materials MRF - <strong>London</strong> Remade Paper Eco Site<br />

400,000 (with plans to<br />

paper, cardboard, (Crayford, Bexley)<br />

increase<br />

plastic bottles and Grosvenor<strong>Waste</strong> Management with other<br />

capacity to<br />

aluminium cans partners<br />

550tpa by<br />

2005)<br />

Organic waste<br />

composting<br />

Cleanaway Organics Eco Industrial Site<br />

(Rainham, Havering)<br />

Cleanaway (at their landfill site)<br />

35,000<br />

4.172. The Day Aggregates site processes hard demolition materials such as concrete into<br />

aggregates for re-use in construction. The glass plant processes glass into cullet, mainly<br />

for use in road construction applications but also for specialist products such as tiles.<br />

4.173. Grosvenor <strong>Waste</strong>’s mixed materials site takes dry recyclables from MSW collections<br />

(about 75,000 tpa), mainly from the Western Riverside and East <strong>London</strong> <strong>Waste</strong><br />

Authorities at present, but including some commercial waste (about 25,000 tpa).<br />

However, this may change when new MRFs are built, including one at Smugglers Way<br />

for Western Riverside. <strong>London</strong> Remade assisted in the investment costs of the<br />

separation facility, as well as the associated educational facilities. The recyclables are<br />

separated for reprocessing at other sites, generally outside <strong>London</strong>. The facility is being<br />

redeveloped to increase dry recyclable capacity to 150,000 tpa by 2005.<br />

4.174. Most of the remaining site capacity (about 300,000 tpa) processes paper waste from the<br />

printing industry and other businesses. The paper is sorted into various grades and<br />

transported to a variety of regional, national and international reprocessors. The plant is<br />

fully operational at its current capacity, however, a company representative indicated<br />

that there is substantial capacity for expansion of the site to receive a range of other<br />

recyclables from both large contracts and small businesses. The company is considering<br />

the business case for various expansion options.<br />

4.175. Both of these companies developed their operations as an integrated part of an existing<br />

business, rather than as a stand-alone operation. Grosvenor <strong>Waste</strong> Management’s<br />

mixed materials facility works well with the company’s existing paper recycling business<br />

and Day Aggregates’ C&D recycling plant fits with its construction and haulage industry<br />

background.<br />

4.176. The Cleanaway organics site at Havering was used as a demonstration site for<br />

composting and although <strong>London</strong> Remade’s involvement has now ended Cleanaway<br />

continues to use the site for composting organic waste. While organic waste processing<br />

in <strong>London</strong> has focused on composting, other options are available. In particular, biogas<br />

production from kitchen wastes and other putrescibles is well established in Germany<br />

and is highly relevant to commercial sector wastes such as restaurant waste. A biogas<br />

plant operates at Hoslworthy in Devon, processing cow slurry and abattoir wastes to<br />

generate electricity which is fed into the national grid and producing a fertiliser for use<br />

on local farms. Substantial EU funding was required to make the plant viable.<br />

58