service manual ar-203e ar-203e x ar-m200 ar-m201 model ar-5420

service manual ar-203e ar-203e x ar-m200 ar-m201 model ar-5420

service manual ar-203e ar-203e x ar-m200 ar-m201 model ar-5420

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

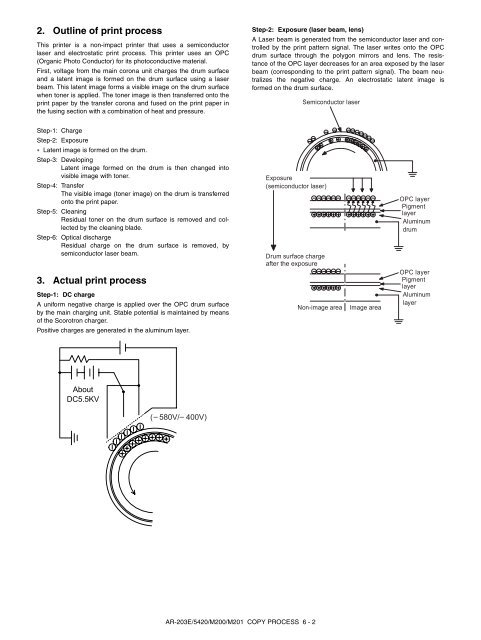

2. Outline of print process<br />

This printer is a non-impact printer that uses a semiconductor<br />

laser and electrostatic print process. This printer uses an OPC<br />

(Organic Photo Conductor) for its photoconductive material.<br />

First, voltage from the main corona unit ch<strong>ar</strong>ges the drum surface<br />

and a latent image is formed on the drum surface using a laser<br />

beam. This latent image forms a visible image on the drum surface<br />

when toner is applied. The toner image is then transferred onto the<br />

print paper by the transfer corona and fused on the print paper in<br />

the fusing section with a combination of heat and pressure.<br />

Step-1: Ch<strong>ar</strong>ge<br />

Step-2: Exposure<br />

∗ Latent image is formed on the drum.<br />

Step-3: Developing<br />

Latent image formed on the drum is then changed into<br />

visible image with toner.<br />

Step-4: Transfer<br />

The visible image (toner image) on the drum is transferred<br />

onto the print paper.<br />

Step-5: Cleaning<br />

Residual toner on the drum surface is removed and collected<br />

by the cleaning blade.<br />

Step-6: Optical disch<strong>ar</strong>ge<br />

Residual ch<strong>ar</strong>ge on the drum surface is removed, by<br />

semiconductor laser beam.<br />

3. Actual print process<br />

Step-1: DC ch<strong>ar</strong>ge<br />

A uniform negative ch<strong>ar</strong>ge is applied over the OPC drum surface<br />

by the main ch<strong>ar</strong>ging unit. Stable potential is maintained by means<br />

of the Scorotron ch<strong>ar</strong>ger.<br />

Positive ch<strong>ar</strong>ges <strong>ar</strong>e generated in the aluminum layer.<br />

About<br />

DC5.5KV<br />

( 580V/ 400V)<br />

AR-203E/<strong>5420</strong>/M200/M201 COPY PROCESS 6 - 2<br />

Step-2: Exposure (laser beam, lens)<br />

A Laser beam is generated from the semiconductor laser and controlled<br />

by the print pattern signal. The laser writes onto the OPC<br />

drum surface through the polygon mirrors and lens. The resistance<br />

of the OPC layer decreases for an <strong>ar</strong>ea exposed by the laser<br />

beam (corresponding to the print pattern signal). The beam neutralizes<br />

the negative ch<strong>ar</strong>ge. An electrostatic latent image is<br />

formed on the drum surface.<br />

Exposure<br />

(semiconductor laser)<br />

Drum surface ch<strong>ar</strong>ge<br />

after the exposure<br />

Semiconductor laser<br />

Non-image <strong>ar</strong>ea Image <strong>ar</strong>ea<br />

OPC layer<br />

Pigment<br />

layer<br />

Aluminum<br />

drum<br />

OPC layer<br />

Pigment<br />

layer<br />

Aluminum<br />

layer